Well my dream has come true! I have been asked to make a modern single plane intake manifold for the Early Hemi. Single plane manifolds are basically non existent for this motor and with the popularity growing on these particular motors there is certainly a need for something like this. Luckily with our EMC effort I have been cooking up a plan for a few years and now it gets to go into action!

Just thought it would be cool to share some of the process with you guys cause it is a TON of work to do. Gene Adams will be building a motor for us to test with and see how well what I come up with works! If all goes well it will be getting casted at a foundry after the core boxes are made.

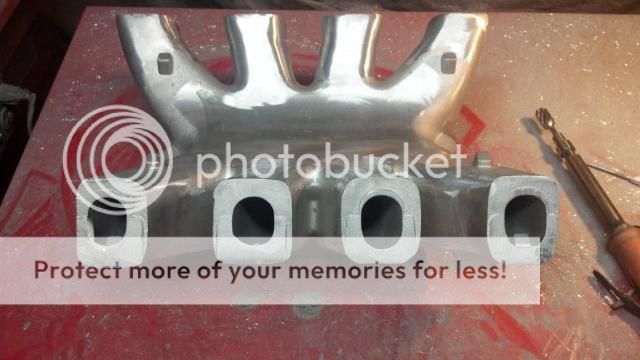

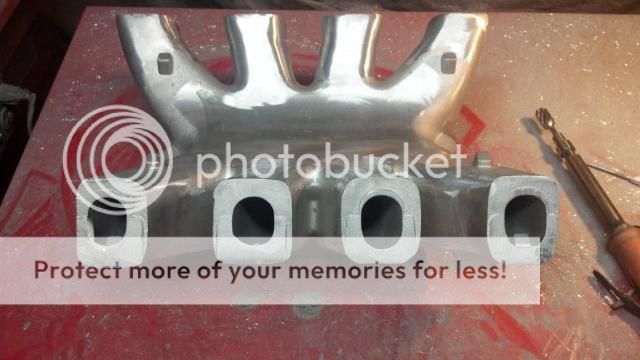

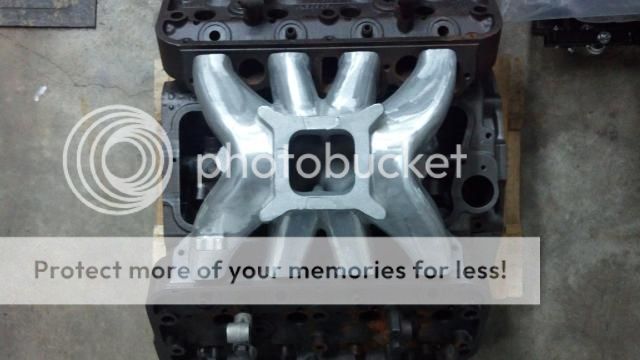

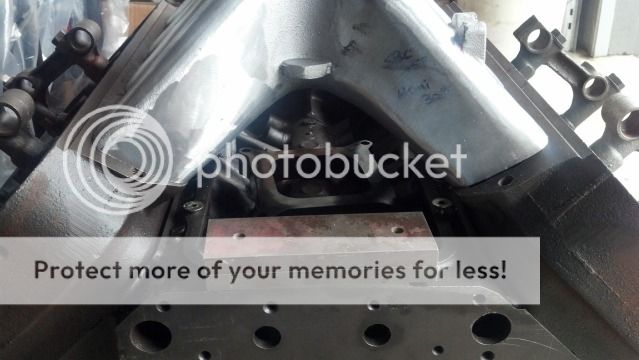

To start with, it took a long time to find a good casting to base this off of and after many attempts I found one I can make work. Its not very easy to find one that has a close enough bore spacing let alone similar bank offset. Its a kick ass piece to start off with!

Nice high runner entry and added plenum volume.

Then the fun begins - removing some of the flange pieces.

Note to self: Buy yourself a Vertical Metal Band Saw!

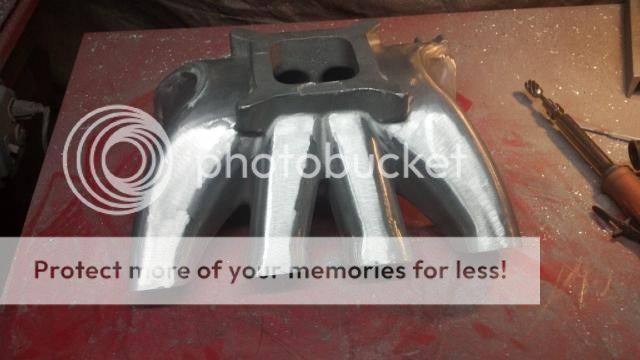

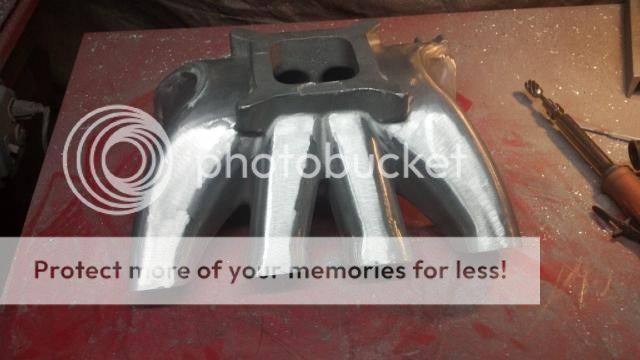

Time to start reshaping the raw unmachined casting.

Smoothed out the exterior to remove any casting flaws. I will bead blast when finished.

Only have a few more things to touch up.

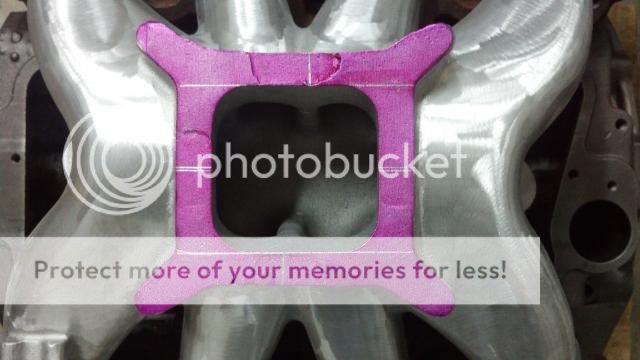

New flanges are being machined by a friend who owns a CNC Shop locally to me. Also have another guy who TIG Welds for me ready and waiting to help weld what I need done. Gene Adam's is sending me a 354 block and some stock heads to be able to mock up everything for proper fitment and before I get to porting on this manifold.

In the meantime I have been crunching some numbers on what I need for a tuned length (3rd Harmonic). With the use of some thick spacers that I need to get to the correct deck height the runner length gets longer. Luckily this is EXACTLY what I need to cater to a broader spectrum of engines. Here is something to get a rough estimate for length.

I will post more as a progress.

Just thought it would be cool to share some of the process with you guys cause it is a TON of work to do. Gene Adams will be building a motor for us to test with and see how well what I come up with works! If all goes well it will be getting casted at a foundry after the core boxes are made.

To start with, it took a long time to find a good casting to base this off of and after many attempts I found one I can make work. Its not very easy to find one that has a close enough bore spacing let alone similar bank offset. Its a kick ass piece to start off with!

Nice high runner entry and added plenum volume.

Then the fun begins - removing some of the flange pieces.

Note to self: Buy yourself a Vertical Metal Band Saw!

Time to start reshaping the raw unmachined casting.

Smoothed out the exterior to remove any casting flaws. I will bead blast when finished.

Only have a few more things to touch up.

New flanges are being machined by a friend who owns a CNC Shop locally to me. Also have another guy who TIG Welds for me ready and waiting to help weld what I need done. Gene Adam's is sending me a 354 block and some stock heads to be able to mock up everything for proper fitment and before I get to porting on this manifold.

In the meantime I have been crunching some numbers on what I need for a tuned length (3rd Harmonic). With the use of some thick spacers that I need to get to the correct deck height the runner length gets longer. Luckily this is EXACTLY what I need to cater to a broader spectrum of engines. Here is something to get a rough estimate for length.

I will post more as a progress.

. Oh well it's only time and money right? It will be worth it in the end.

. Oh well it's only time and money right? It will be worth it in the end.

Comment