So I have gotten a ton done on my Turbo6 into '64 Riviera project but I've also run across so many snags along the way I've just started writing them down so when I have to pull the motor again to fix some I can do them all.

I have the downpipe and the mid-pipe 90% done, the crossover is around 75% done. The downpipe is missing the bung for the WBO2 and thethe wastegate pipe which I can get away with but I'm trying to get everything done now. The midpipe just needs a pair of hangers and a bend after the resonator so I can clamp the axle section to it when I get to fabricating it. The crossover needs a slip joint added to help with expansion. The bad on the exhaust is that I need to pull everything including the headers to fabricate the wastegate tube and add the bungs.

The trans cooler lines hit the starter, crossover tube, frame, and just about anything coming close so I need to make new ones. At least I have the cooler mounted. It does however mean that I have 2 holes to weld up from the clamps holding the lines and wasted around 16ft of 3/8in cooler line.

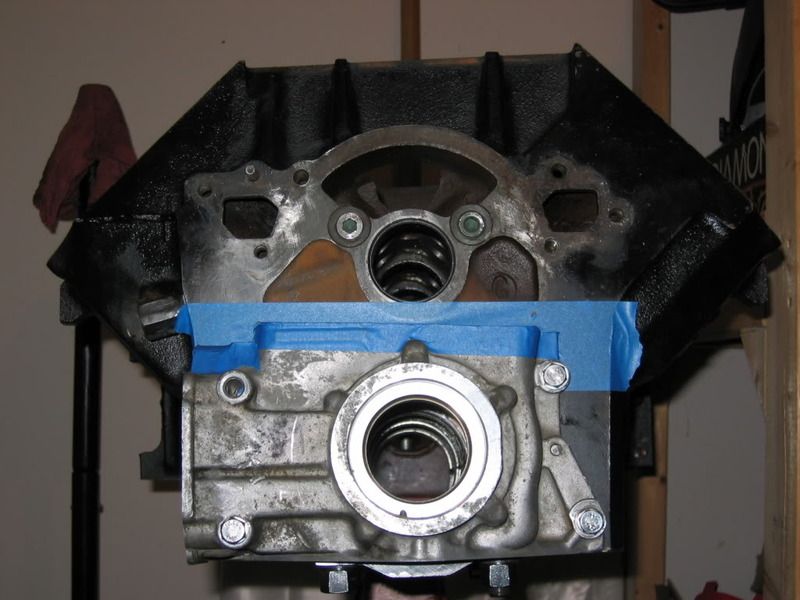

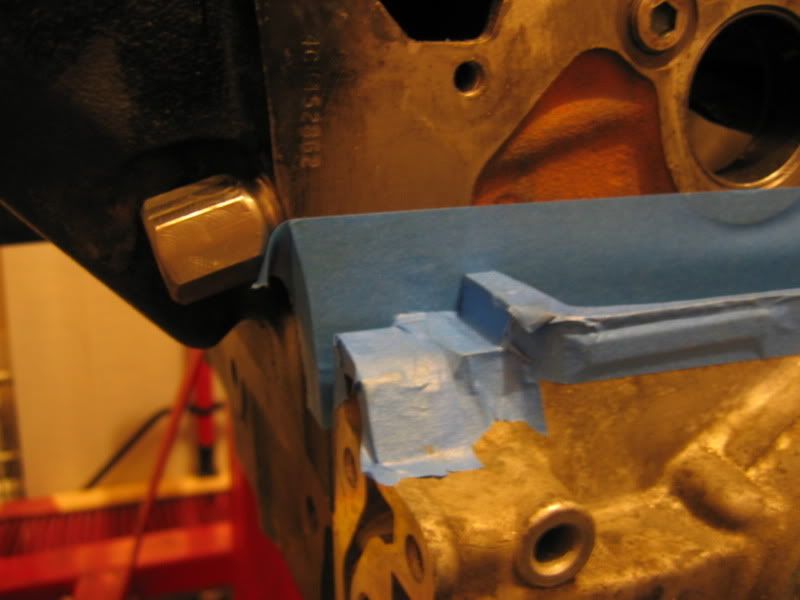

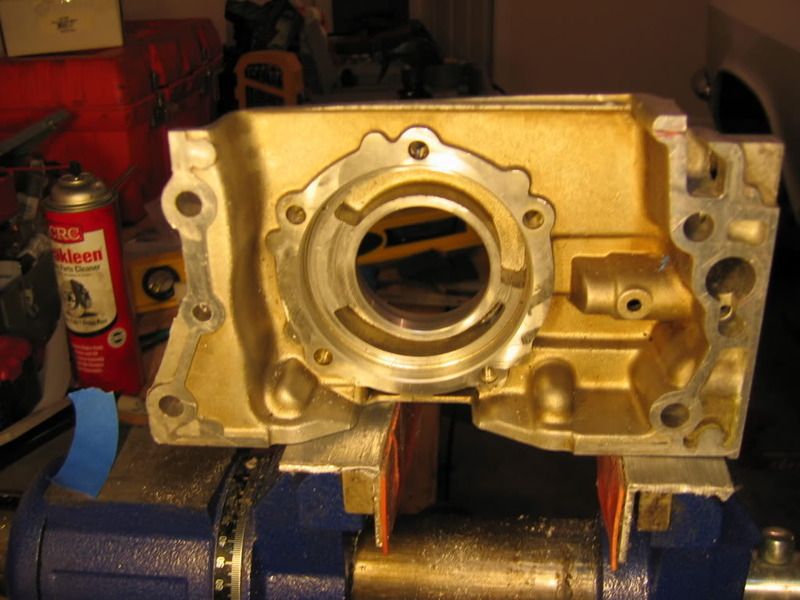

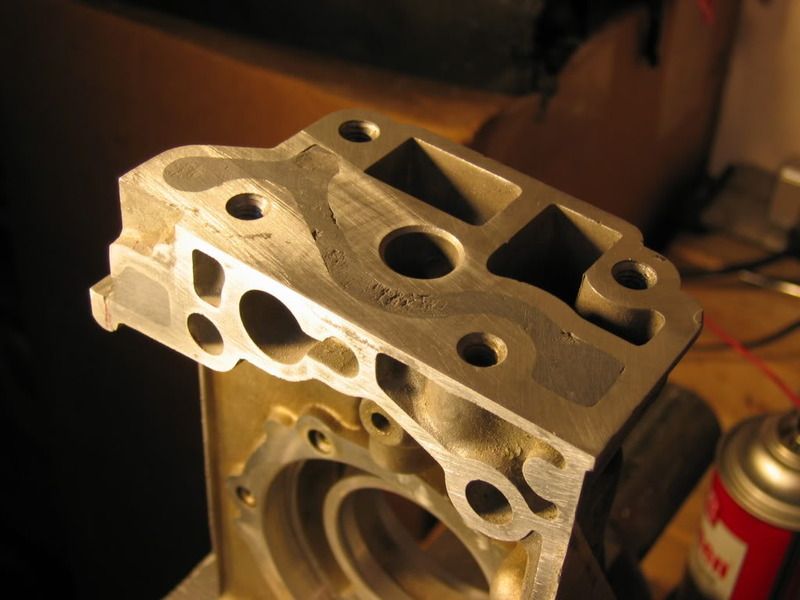

The transmission is in and thankfully I didn't fill it with fluid after replacing the pan gasket because the engine has to come out because one of the rods hits the windage tray and the drainplug leaks on the oil pan. I am about 2 clicks away from adding an oil cooler and changing my oil plumbing again. I guess this gives me a chance to pretty things up a bit while the engine is out of the bay

I'm trying to take more piectures so maybe as I dunk the engine again I'll get enough to actually make a documentary of how I did it on photobucket.

And I thought I was so close.

I have the downpipe and the mid-pipe 90% done, the crossover is around 75% done. The downpipe is missing the bung for the WBO2 and thethe wastegate pipe which I can get away with but I'm trying to get everything done now. The midpipe just needs a pair of hangers and a bend after the resonator so I can clamp the axle section to it when I get to fabricating it. The crossover needs a slip joint added to help with expansion. The bad on the exhaust is that I need to pull everything including the headers to fabricate the wastegate tube and add the bungs.

The trans cooler lines hit the starter, crossover tube, frame, and just about anything coming close so I need to make new ones. At least I have the cooler mounted. It does however mean that I have 2 holes to weld up from the clamps holding the lines and wasted around 16ft of 3/8in cooler line.

The transmission is in and thankfully I didn't fill it with fluid after replacing the pan gasket because the engine has to come out because one of the rods hits the windage tray and the drainplug leaks on the oil pan. I am about 2 clicks away from adding an oil cooler and changing my oil plumbing again. I guess this gives me a chance to pretty things up a bit while the engine is out of the bay

I'm trying to take more piectures so maybe as I dunk the engine again I'll get enough to actually make a documentary of how I did it on photobucket.

And I thought I was so close.

Comment