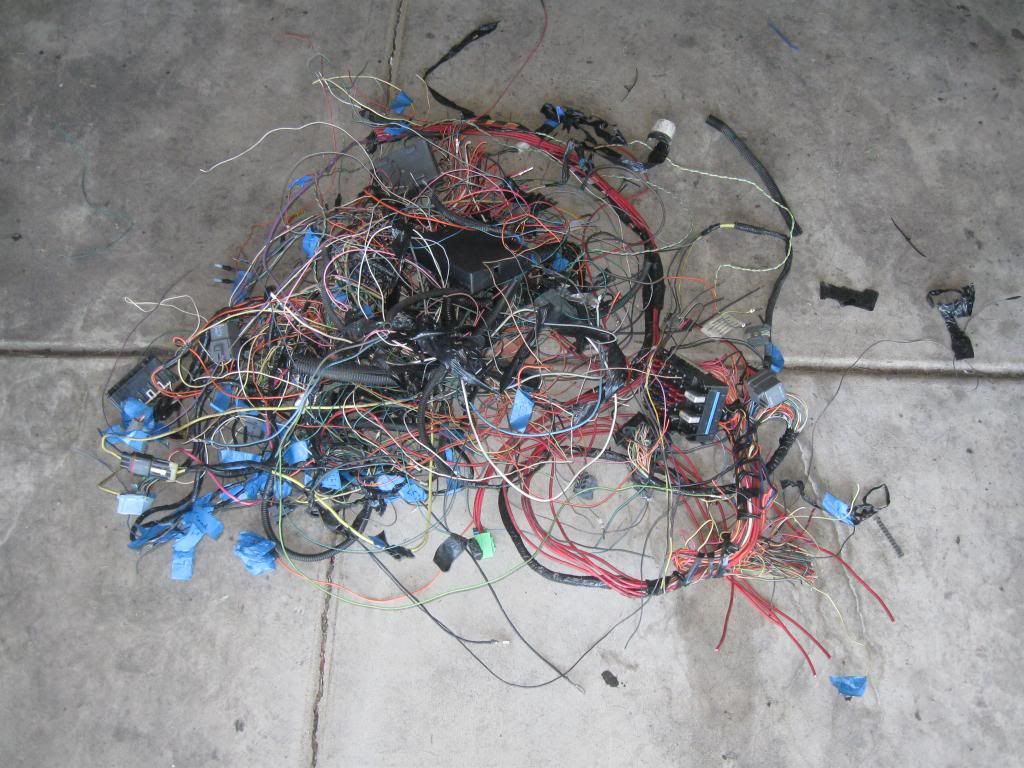

Decided that I wasn't going to mess around and just try to bandaid the wiring situation and went for the full gusto rewire of at least the harness into the interior.

As such that meant that I ripped out the entire passengers side feed through and started disconnecting everything in the interior. I'm down to the CEL, OBDII plug, switched 12V (it's unique in that it's hot in both start and run instead of just run like the stock switched power), AC request (to up the idle and switch on the fans), tach signal, performance shift (dual shift tables), and the stoplight switch for the brakes (to signal TCC unlock) left needed. Now there are a ton of wires going into the interior still and around 50% of the ones I want to go into the interior through the drivers pass through are in the passengers side harness. I got the drivers side unbundled today and soon I'll get the engine bay crossover unbundled so I can pull out and repin or solder the connections to matching colour wires on the drivers side.

Depending on time I might build my transmission control box as well and put it on the inner fender. Basically need to invert a solenoid polarity with a relay and build a logic converter for the 4L80E range switch into the 4T65E logic diagram so the ECM can take charge when I put the 4L80E in.

As such that meant that I ripped out the entire passengers side feed through and started disconnecting everything in the interior. I'm down to the CEL, OBDII plug, switched 12V (it's unique in that it's hot in both start and run instead of just run like the stock switched power), AC request (to up the idle and switch on the fans), tach signal, performance shift (dual shift tables), and the stoplight switch for the brakes (to signal TCC unlock) left needed. Now there are a ton of wires going into the interior still and around 50% of the ones I want to go into the interior through the drivers pass through are in the passengers side harness. I got the drivers side unbundled today and soon I'll get the engine bay crossover unbundled so I can pull out and repin or solder the connections to matching colour wires on the drivers side.

Depending on time I might build my transmission control box as well and put it on the inner fender. Basically need to invert a solenoid polarity with a relay and build a logic converter for the 4L80E range switch into the 4T65E logic diagram so the ECM can take charge when I put the 4L80E in.

)

)

Comment