Love this build - so many cool ideas!! Nice to see an update, thanks.

Announcement

Collapse

No announcement yet.

Little Engine, Little Tires, Little Nitrous...

Collapse

X

-

Love the clutch slipper I can see where that would really help out of the hole, does it hurt any on higher shifts like 3-4?

Is there anything you can not build!?Last edited by Russell; November 24, 2012, 08:57 AM.

Comment

-

I faceplated the Toploader, so i can shift it clutchless by bouncing off the rev limiter.

Where the Hillbilly Clutch Slipper really shines though is it's ability to get more power thru a weaker transmission than you would otherwise be able to. When using the clutch pedal, engagement on every shift is softened. I 1st came up with it when i was trying to get more out of the Saginaws. I had already had the Toploader ready to go in, but i decided to keep running the Saginaws just to see how much farther i could go. I was able to run 6.45 and a 1.456 60' using a Saginaw 4spd with a 3.50 ratio gearset, without taking the teeth off of the input shaft or 1st gear on the cluster. I did start twisting the mainshafts tho, a Hillbilly Clutch Slipper can't fix that. That's the point where the Toploader went in.Last edited by weedburner; November 24, 2012, 01:57 PM.

Comment

-

Just got through the whole thread..........pretty amazing stuff your doin.

I zeroed in on the headers.......wish your header guy was in my neck of the woods.Thom

"The object is to keep your balls on the table and knock everybody else's off..."

Comment

-

--------------------------------------------------------------------------------

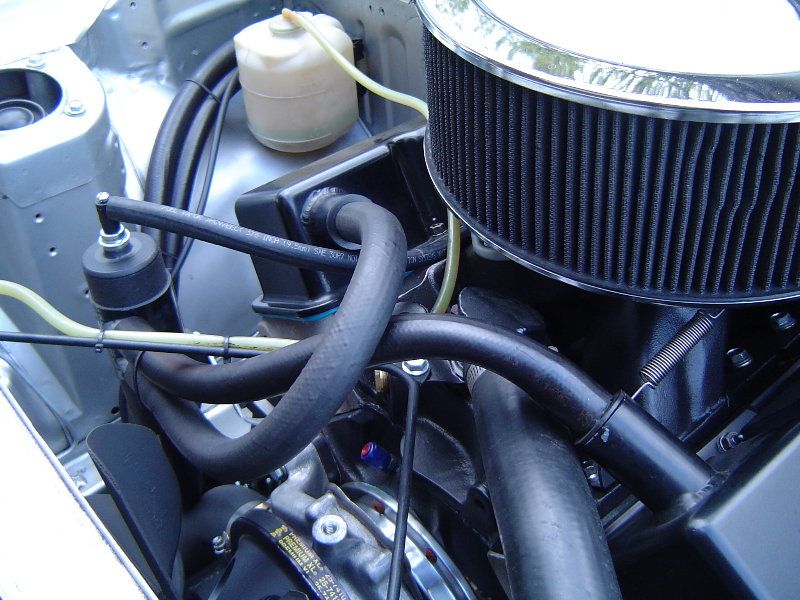

Here's an update...I went to a 3pc style bellhousing...blockplate, midplate, bell/can. Now i can remove the engine from the car with the flywheel and clutch, and leave the bell and transmission mounted in the car. I can also remove the transmission/bell/clutch/flywheel from the car without supporting the rear of the engine. I also added a couple external "ears" to the block plate, which gives me some easy attachment points for lifting the engine...

I'll take some pics of the engine lifting fixture i made for it. It plugs into the blockplate's added "ears" and into an "eye" that screws into a hole in the top of the waterpump. It fits over the complete engine with the aircleaner and distributor in place. Before i was always using some type of hokey chains trying to find a perfect balance point without damageing something. Now i have a dedicated fixture that plugs in and makes the job easy. Been thinking about attaching the radiator to the engine just to make choosing between a couple engines that much easierLast edited by weedburner; December 5, 2012, 06:04 PM.

Comment

-

That is really nice!

I wanted to 302 a first gen, because of the dizzy mostly, and being able to just flip the x-member. I retrieved an old 350 from my sisters, thinking about a second gen for it . I see them quite a bit with blown up rotary / genius turbo tuner meltdown remnants under the hood.

I may have asked this already, sorry if it's a repeat. I'm pretty sure I saw this car on Granny's page, can't find it at the moment. It's really a neat build, thanks for sharing. Last edited by Beagle; December 7, 2012, 09:38 AM.Flying south, with a flock of bird dogs.

Last edited by Beagle; December 7, 2012, 09:38 AM.Flying south, with a flock of bird dogs.

Comment

-

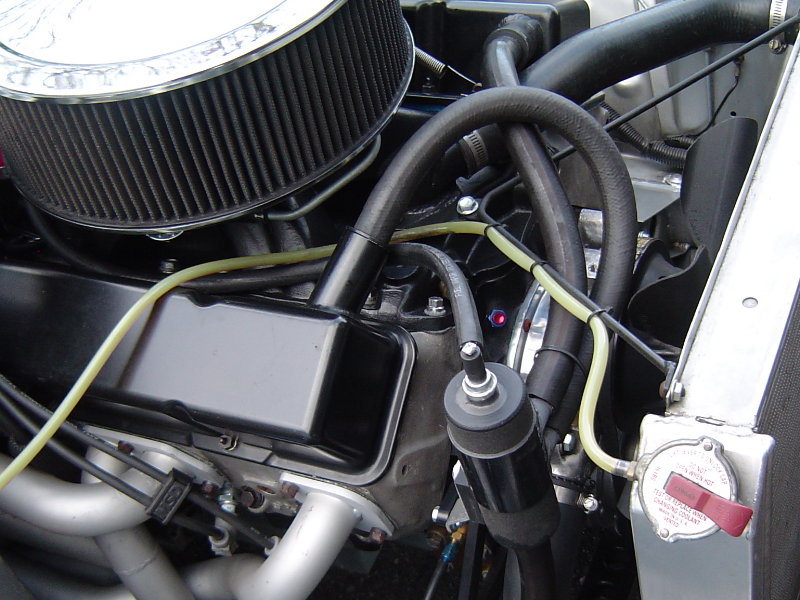

Here's another update, an improvement on the electric crankcase vacuum pump system from last year...

... i added a modified pcv valve to the top of the separator to provide crankcase vacuum for street driving. I now draw 6"Hg in the crankcase while going down the hiway without using the electric pump. When i'm on the hose, the electric pump comes on. A header style check valve on the electric pump's outlet hose allows me to shut off the electric pump and still draw a vacuum using the pcv system...

Here's a pic of the inside of a common chevy pcv valve...

I added a screw to the top of the plastic elbow so that i can now use the valve as an adjustable restriction in my sealed pcv system...

Here's a shot of the added adjustment screw...

I cut this valve apart on a lathe. If i wanted to play with the internal calibration and put it back together for use, i could use a piece of 3/4" id shrink tbe to seal the seam.

I've never gotten more than a drop of oil in the bottom of the separator tank, the pcv is not pulling any oil either...

I've got low tension (gapless top) rings in this engine, and it draws about 16"Hg in the intake. 4 spd manual, 3.73 gears, and no overdrive. It's about 2800rpm down the freeway, so without a good vacuum on the crankcase, it goes thru a quart of 5W-20 synthetic in about 250 miles. The electric vac pump worked ok by itself, but I'm getting around 20mpg out of this combo, so i wanted to squeeze a little more mileage out of it. My goal here was to take some load off of the alternator by not running the electric pump all the time (it pulls 12a). The vac pump on 12v pulled 4"Hg in the crankcase, but now I pull 6"Hg using the pcv system alone, the electric pump only has to come on when i'm on the hose.

700hp and 20mpg on 87 octane...

Comment

-

Who's electric vacuum pump are you using and how has it held up to running for longer than drag passes on a regular basis? I'd like to add an electric to my Bonneville motor but seems like it would burn up from use over 3-5min at WOT.

Thanks,Central TEXAS Sleeper

USAF Physicist

ROA# 9790

Comment

-

I'm using the Delco 215-425, pulls 4"Hg on 12v, but last year i had mine wired to run thru a dropping resistor during normal street driving so it would run cooler and last longer. For spray, the dropping resistor was bypassed for a full system 14.5v.

During constant duty on 12.5v, i've seen temps over 325F around the brushes, but it takes around 10-15 min to get that hot. If you want to run one at a constant system voltage w/ an alternator, i would suggest removing the rubber cover so that the motor can run a little cooler, maybe even clamping a heat sink to the outside of the can. I suspect that most of those that are getting long life with an alternator system probably have a wiring issue, and are likely experiencing a voltage drop that is reduceing their motor temps.

I've ran these pumps with cordless tool 18v battery packs, and they drew 8"Hg. I'm working on fitting my spare pump with a brushless motor and controller, which will allow it to spin more rpm, run cooler, and draw less current.

Comment

-

Great info!Originally posted by weedburner View PostI'm using the Delco 215-425, pulls 4"Hg on 12v, but last year i had mine wired to run thru a dropping resistor during normal street driving so it would run cooler and last longer. For spray, the dropping resistor was bypassed for a full system 14.5v.

During constant duty on 12.5v, i've seen temps over 325F around the brushes, but it takes around 10-15 min to get that hot. If you want to run one at a constant system voltage w/ an alternator, i would suggest removing the rubber cover so that the motor can run a little cooler, maybe even clamping a heat sink to the outside of the can. I suspect that most of those that are getting long life with an alternator system probably have a wiring issue, and are likely experiencing a voltage drop that is reduceing their motor temps.

I've ran these pumps with cordless tool 18v battery packs, and they drew 8"Hg. I'm working on fitting my spare pump with a brushless motor and controller, which will allow it to spin more rpm, run cooler, and draw less current.

I might even consider putting a liquid cooler (maybe pirated from a friends old liquid CPU cooler) on the motor to help keep it cool. Is this the LT1 pump or some other GM unit?

Thanks,Central TEXAS Sleeper

USAF Physicist

ROA# 9790

Comment

Comment