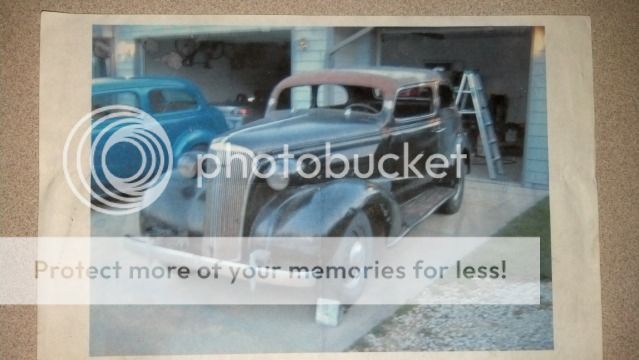

Not really mine, actually its my dad's street rod project but he doesn't use a computer period! This is a really nice ride and I wanted to share since he won't. He bought the car a few years back over in Iowa for a song - all original running and rust free! I think he paid $3800 for it?

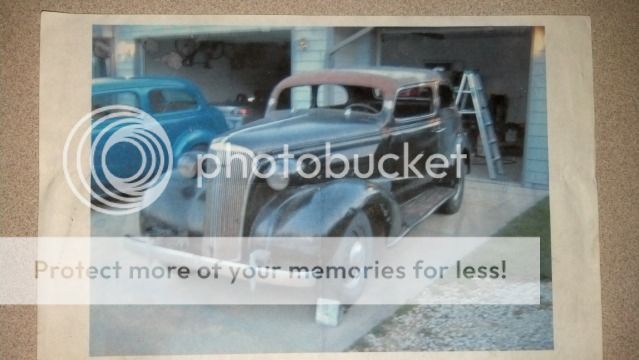

We stripped the car down and sent it to a local guy who chopped the top 2 inches and tilted the rear glass forward some. This old guy is simply AMAZING at what he does, the precision and the geometry used to chop a top. Everything was TIG welded even down to the window trim rings for the inside. Very reasonably priced too for the quality of work he does out of his one car garage! This pic was taken after the top got chopped and it is sitting next to a stock bodied car just like his.

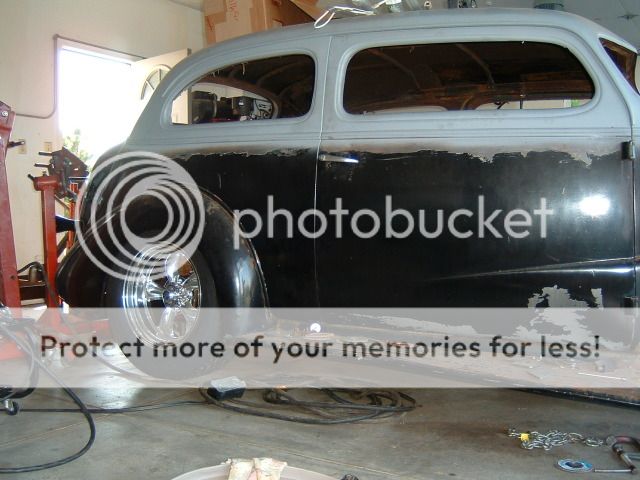

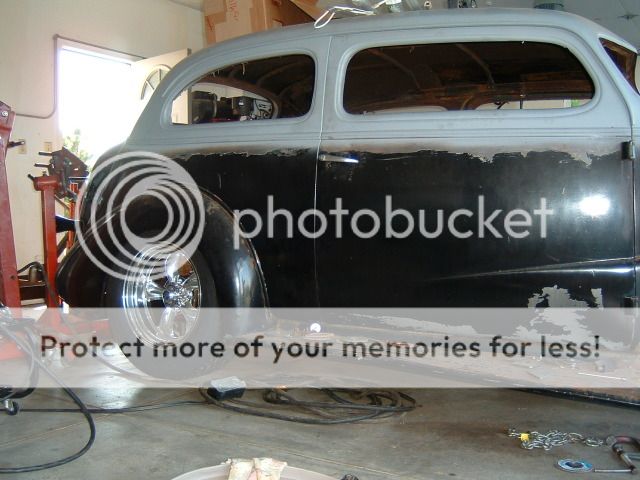

Next was getting the main shell body work done before which included a new firewall for the SBC to have some room. Very little work needed to be done since it was in such good shape. We needed some more room in the rear wheel wells since I went with a wider tire so we added a 2" filler piece the the rear fender (not pictured) which not only moved the metal out but also lowered the wheel well opening to create a lower look. Now the rear fender and front fender share the same width (rear originally narrower) and it looks properly proportioned. We also started doing the chassis work - installed a Mustang II front suspension, rear triangulated four link w/ Ford 9", etc.

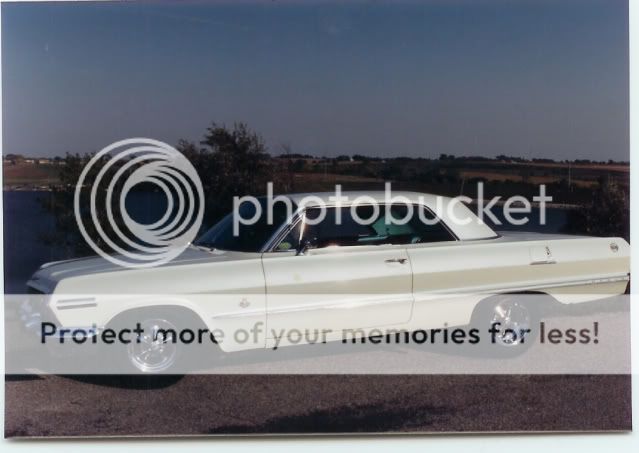

Once that was done we then removed all of the suspension parts down to the bare frame. My dad spent weeks smoothing out the frame but it certainly paid off when looking at the details in a nice satin black finish. I ordered up some wheels and tires for it to help give it the proper stance (I think I do a decent job getting the correct stance) and we loaded up the frame with fuel tank, fuel line, brakes, brake line, etc so it would be a finished rolling chassis.

Then the car went off to another shop to do some very meticulous and detailed work - suicide doors, hidden hinges on doors and trunk, shaved door handles and trunk, gas struts for the trunk, 3 piece hood with removable sides (originally a gull wing design), and electric locks. It was been at this shop for over a year and is nearly complete. We are set to go pick it up shortly so you will have to wait to see the pics in its current state!

We stripped the car down and sent it to a local guy who chopped the top 2 inches and tilted the rear glass forward some. This old guy is simply AMAZING at what he does, the precision and the geometry used to chop a top. Everything was TIG welded even down to the window trim rings for the inside. Very reasonably priced too for the quality of work he does out of his one car garage! This pic was taken after the top got chopped and it is sitting next to a stock bodied car just like his.

Next was getting the main shell body work done before which included a new firewall for the SBC to have some room. Very little work needed to be done since it was in such good shape. We needed some more room in the rear wheel wells since I went with a wider tire so we added a 2" filler piece the the rear fender (not pictured) which not only moved the metal out but also lowered the wheel well opening to create a lower look. Now the rear fender and front fender share the same width (rear originally narrower) and it looks properly proportioned. We also started doing the chassis work - installed a Mustang II front suspension, rear triangulated four link w/ Ford 9", etc.

Once that was done we then removed all of the suspension parts down to the bare frame. My dad spent weeks smoothing out the frame but it certainly paid off when looking at the details in a nice satin black finish. I ordered up some wheels and tires for it to help give it the proper stance (I think I do a decent job getting the correct stance) and we loaded up the frame with fuel tank, fuel line, brakes, brake line, etc so it would be a finished rolling chassis.

Then the car went off to another shop to do some very meticulous and detailed work - suicide doors, hidden hinges on doors and trunk, shaved door handles and trunk, gas struts for the trunk, 3 piece hood with removable sides (originally a gull wing design), and electric locks. It was been at this shop for over a year and is nearly complete. We are set to go pick it up shortly so you will have to wait to see the pics in its current state!

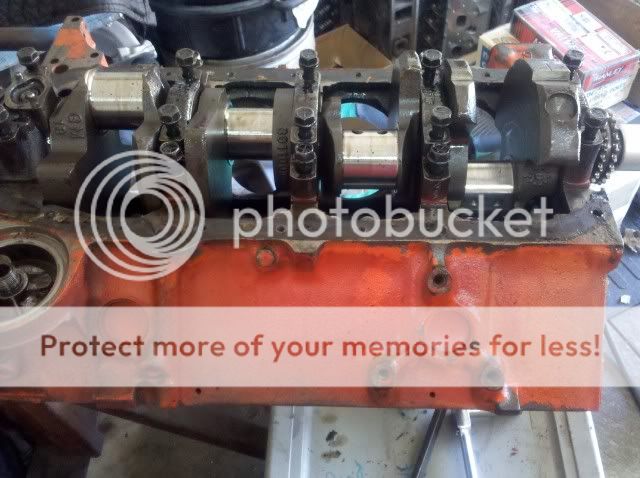

That is a Barry Grant Six Shooter so only the center carb has an idle circuit and the front/rear carbs are the "secondary" with how the linkage is setup (blocked idle circuits). I haven't tuned one of these before so it may be a challenge. Not sure where the linkage is currently at but it will be in the car this winter.

That is a Barry Grant Six Shooter so only the center carb has an idle circuit and the front/rear carbs are the "secondary" with how the linkage is setup (blocked idle circuits). I haven't tuned one of these before so it may be a challenge. Not sure where the linkage is currently at but it will be in the car this winter.

Comment