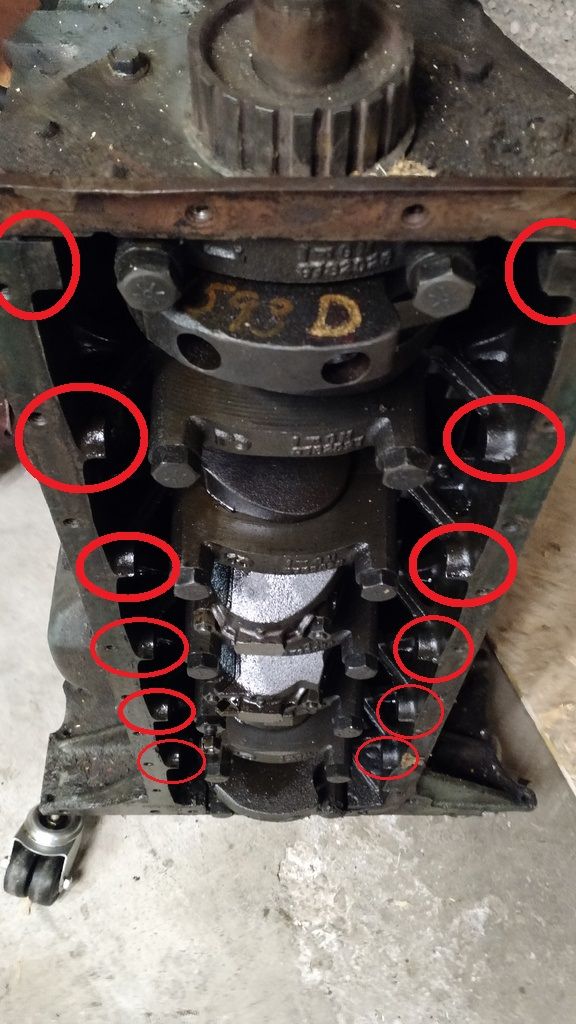

Is this a stock pump, or a boosted high volume/high pressure deal?

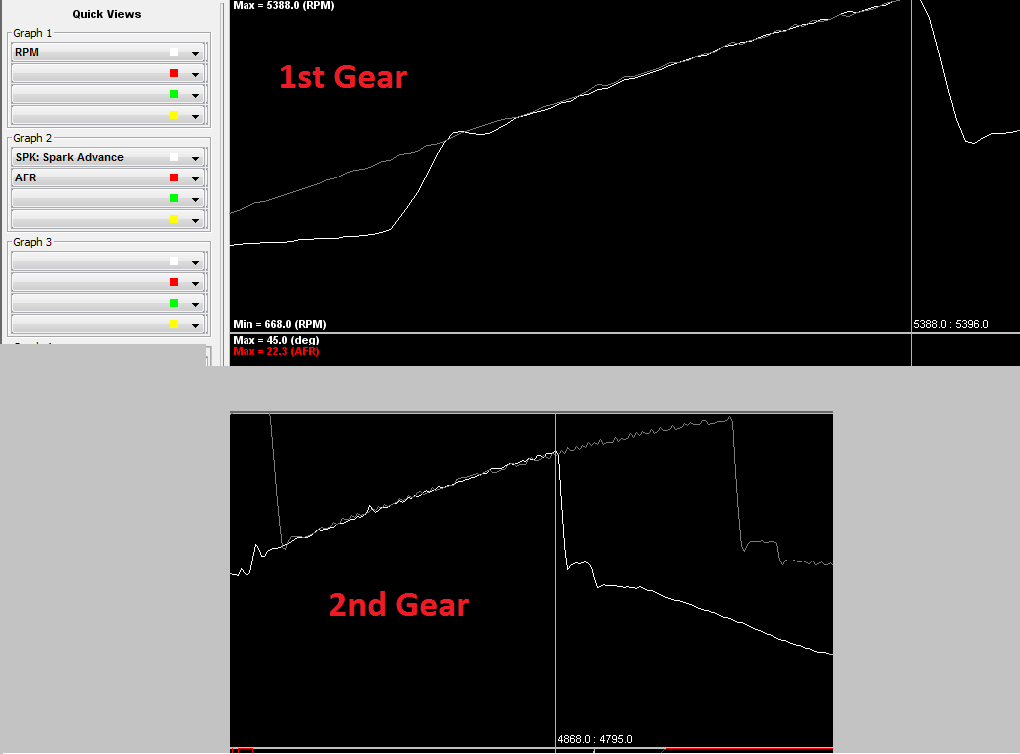

Might be on the verge of sucking the pan dry at higher rpms? Even a stock pump can suck a pan dry at higher than stock rpms.

Maybe add pan capacity with a bump-out somewhere? Should be room on one side or the other....an extra quart or three goes a long ways.

I run what is called a "deep-sump" on the stroker vw engines I build, adds an additional 4 quarts. With 2.5 quart stock capacity its nearly a necessity, but the theory still applies - the OEMs didn't design in an overabundance of pan capacity.

Might be on the verge of sucking the pan dry at higher rpms? Even a stock pump can suck a pan dry at higher than stock rpms.

Maybe add pan capacity with a bump-out somewhere? Should be room on one side or the other....an extra quart or three goes a long ways.

I run what is called a "deep-sump" on the stroker vw engines I build, adds an additional 4 quarts. With 2.5 quart stock capacity its nearly a necessity, but the theory still applies - the OEMs didn't design in an overabundance of pan capacity.

Yep. Different approaches to the same problem. I was just taking the easy way out, lol.

Yep. Different approaches to the same problem. I was just taking the easy way out, lol.

Comment