Well that's what you get for washing it... Sucker!

Glad it was an easy fix.

Announcement

Collapse

No announcement yet.

The Silver Buick's 1969 Firebird OHC six project.

Collapse

X

-

The Final Count Down! Tied up a lot of little loose ends and now going on to packing.

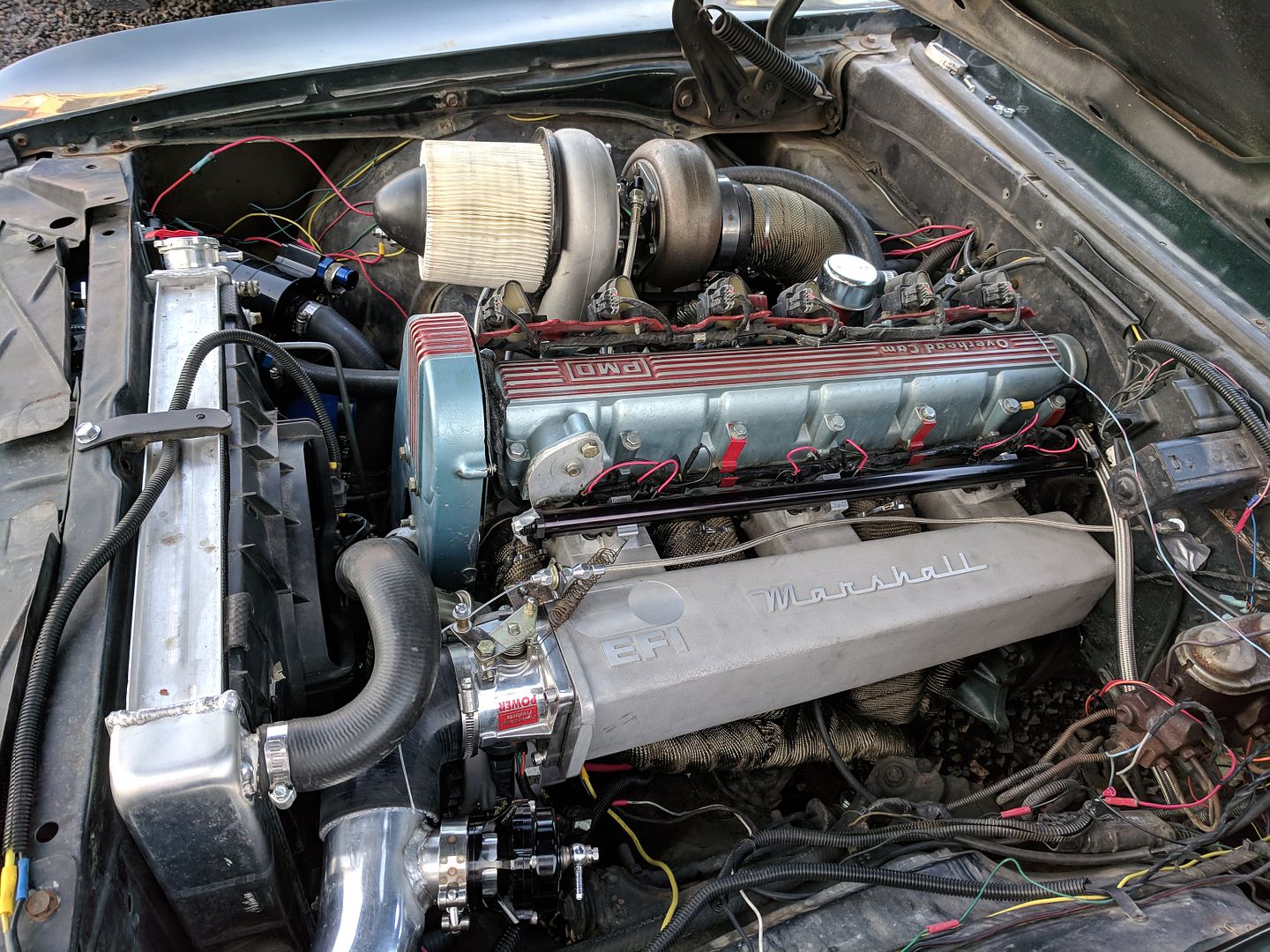

A gratuitous engine shot.

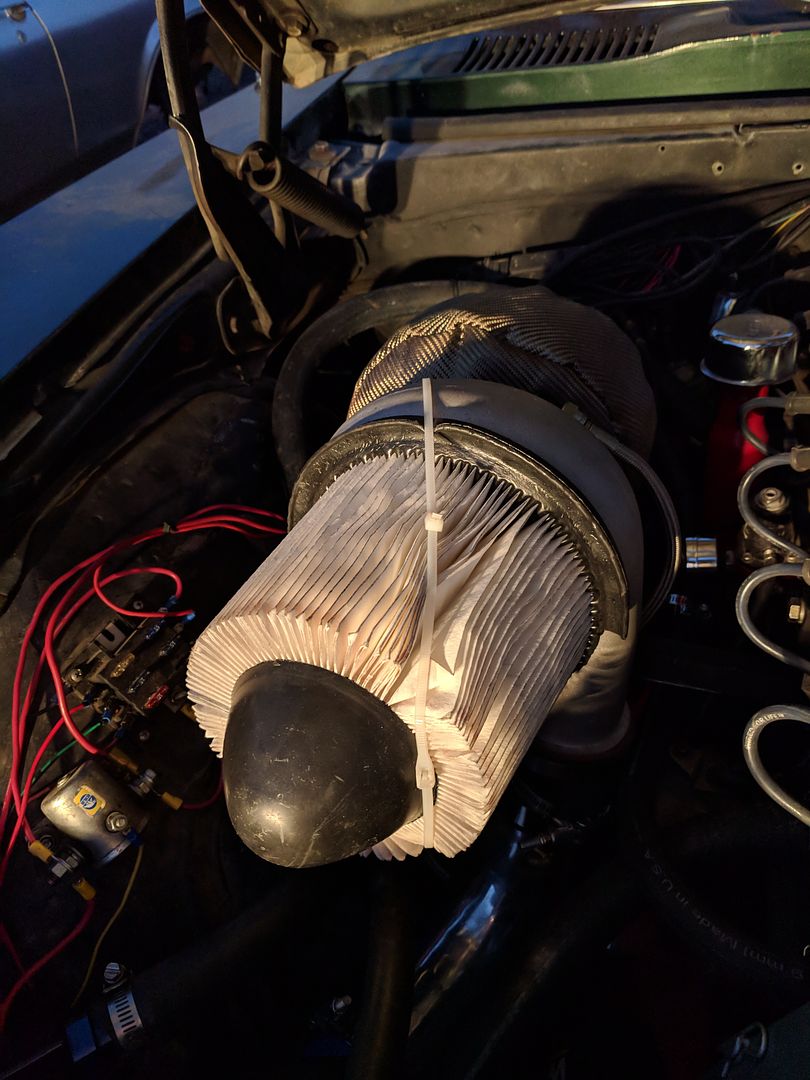

I need to pick up two more clamps, but have moved the air filter into the fender.

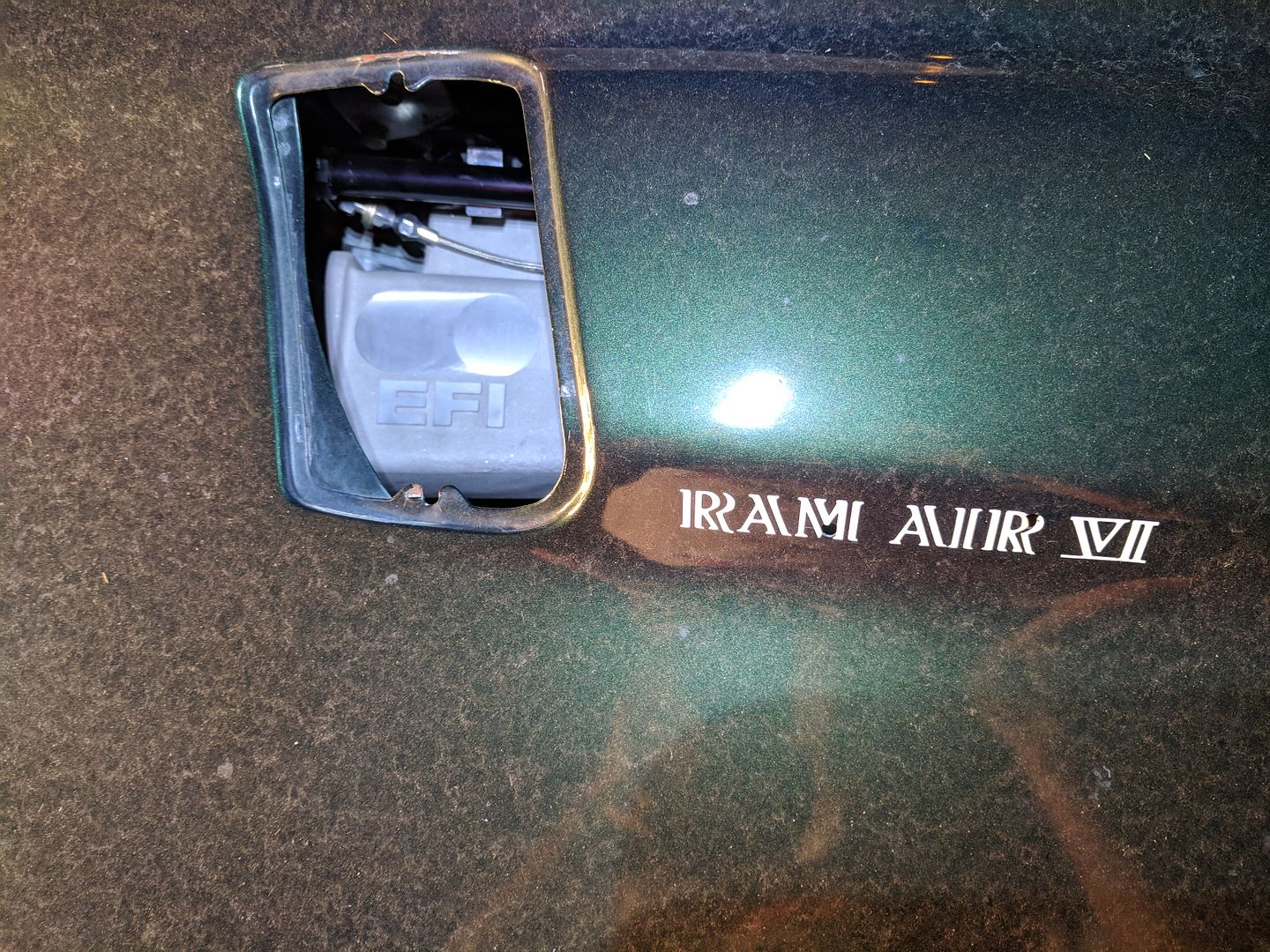

I thought about just reading the speed off the display, which will always work in a pinch, but decided to step up to an actual speedometer/trip/odometer gauge. It's a Summit brand electric speedometer. I don't have the time to pull the dash to tuck the wires, but this will get me by for now. I'll get a black wrapping on the wires tomorrow. Supposedly will report 0-60 and quarter mile times. Uses 8,000 pulses per mile output from the Mega/Microsquirt.

I'm going to change the oil tomorrow and figured I'd check the level based on how much oil is added. Here is the level with 4 quarts. Figure about 1/2 quart is in the oil filter and another quart is running through the engine, with a stock 5 quart fill it it should be right under the baffle. Its like the engineers knew what they were doing...

Leave a comment:

-

Great to hear it is on the road, well done TSB.

Another hurdle over just a few more to go till the end of Drag week, I really hope you can get over them all!

Leave a comment:

-

Sorry for the SNAFU but that's Hot Rodding! At least it was an easy fix.

BTW - I run Water Wetter and ECTA seems to be OK with that. As I understand it that gives some water pump lube and corrosion protection as well as better heat transfer and evidently doesn't mess up the track in the event of an - event.

Dan

Leave a comment:

-

I've been busy. Time is getting short! In short, I've driven it to work two days in a row, had one hiccup and have made 4 psi of boost at half throttle at 2500 rpm, so I do not think I'll have a spooling problem.

I was really excited to drive it to work yesterday, I stopped at a car wash on the way to work, washed the car, then about ten minutes later sitting in stop and go traffic (mostly stopped) I noticed the coolant temperature rising. Ordinarily it rises at a stop until 200ºF when I'd have the fan kick on then within 10 seconds it starts dropping. This time by 203ºF I knew something was amiss. The computer said the engine fan should be on, but it didn't seem like it, so I pulled into a Home Depot parking lot to check it out. Got out of the car and I couldn't hear the fan then right as I was reaching for the hood latch this happen!

Okay, it turned out that the heater hose popped off the radiator, and upon inspection I think the hose clamp was loose. All the steam is from the electric water pump still pumping hot water out, not necessarily from boiling over. The hose clamp was on the ground and I didn't have to loosen it at all to put it back on.

So I got 5 gallons of water from Home Depot and was on my way. I was running straight water anyways because tracks don't like glycol spills.

My poor just washed car

My Ford air filter was a casulty of the spill. It turned into mush (I took this picture about 30 minutes before steaming).

So I picked up some 4" couplers yesterday to put a proper filter on it. The tube is a scrap piece of exhaust tubing I had laying around. Tonight I'll cut one that will put the filter in the fender well for cooler air. Though so far, yesterday and today at anything over a few mph the intake air temperature sensor reads ambient temps. Which beats the +40ºF the stock manifold set always registered!

I'm still tuning on it. Every drive yesterday it was running really lean so I didn't want to push it. Driving to work this morning I finally had it giving me mid-10's AFR readings as it was getting into boost. Still have not gone over 65% throttle as part of the tuning process. But good to know it can start making boost below 3,000rpm. I currently have the stiffest single wastegate spring that came in the kit installed. I have the other springs on hand to adjust it as necessary. I want to keep the boost down to around 8psi until my good engine is together.

The transmission is pretty good too! I'm still adjusting the shift points for when to be in and out of overdrive, but it'll bark the tires going into second gear with just a little extra throttle. I'll probably dial that down a little, but it's been fun yesterday and today. It runs smooth well into the 80mph's.

I think the intake and headers have upped the naturally aspirated power, but its hard to tell since I also upped the gear ratio from 3.42 to 3.89 as well. I think I have enough fuel pump to get me to around 350 horsepower, maybe even 400 horsepower, which would be double what it was making before.

Now to get the trailer sorted. I head out Tuesday!

- Likes 2

Leave a comment:

-

Soooo close! I was hoping to fire it up yesterday, but I didn't have the correct adapters for the fuel line to fuel rail. I also need some fittings and hose for moving the cooling lines around the exhaust. Hopefully get that taken care of today or tomorrow. I will then start on cleaning up all the wiring, but it will be minimal because I plan on making a new engine wiring harness to go with the new engine.

The turbo and hoses are not clamped down yet as I plan on cleaning out the intake tubes before running the turbo, and I plan on removing the turbo for first fire up to blow any remaining crap in the exhaust header out first.

8 days until I head out on a 3500+ mile journey!

- Likes 1

Leave a comment:

-

So moving back to the engine in the Firebird. In good news, I put two different mechanical oil pressure gauges on it today and they read 8-10psi higher than the gauge in the car, so the engine is probably not wounded like I thought. I'm feeling a lot better about using it.

I wired up the battery disconnect switch. It's a 4-pole one so it not only kills the main power wire, but also the dedicated power feed to the ECU which inturn shuts off the fuel pump/engine. Don't have to worry about the alternator keeping it running.

121 views, 15 likes, 1 loves, 3 comments, 1 shares, Facebook Watch Videos from Randal Burns: Checked one more thing off the list. Just need to label it.

121 views, 15 likes, 1 loves, 3 comments, 1 shares, Facebook Watch Videos from Randal Burns: Checked one more thing off the list. Just need to label it.

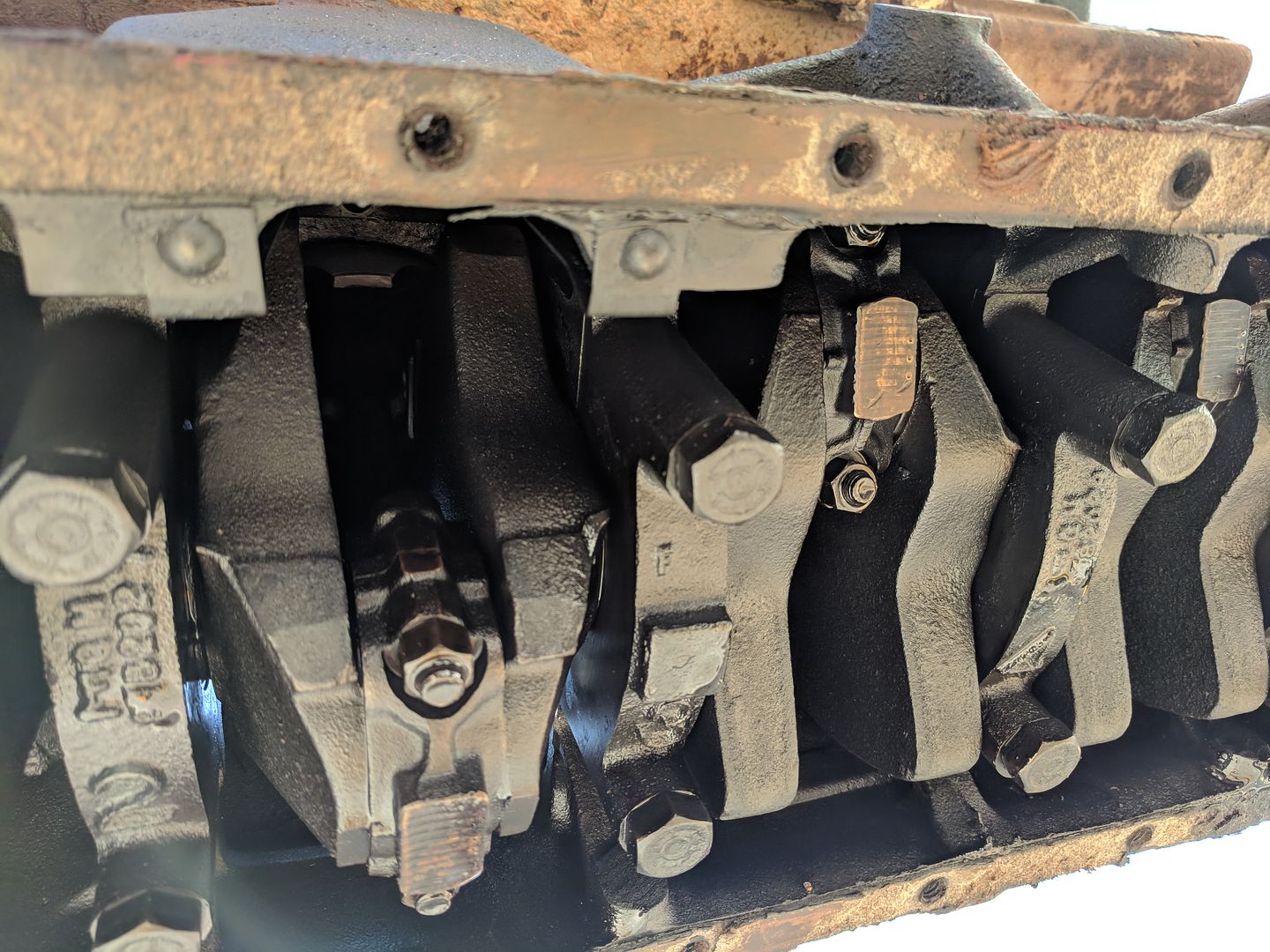

Then started on removing the manifolds from the engine to mock up the intake and header to make sure there weren't any surprises.

The 2.5" exhaust with glass pack has served me well, but is now replaced with a 4" pipe.

Intake manifold fits. Of course its not port matched to this head, its about 1/8" off.

I do like how this is looking!

The headers clear everything!

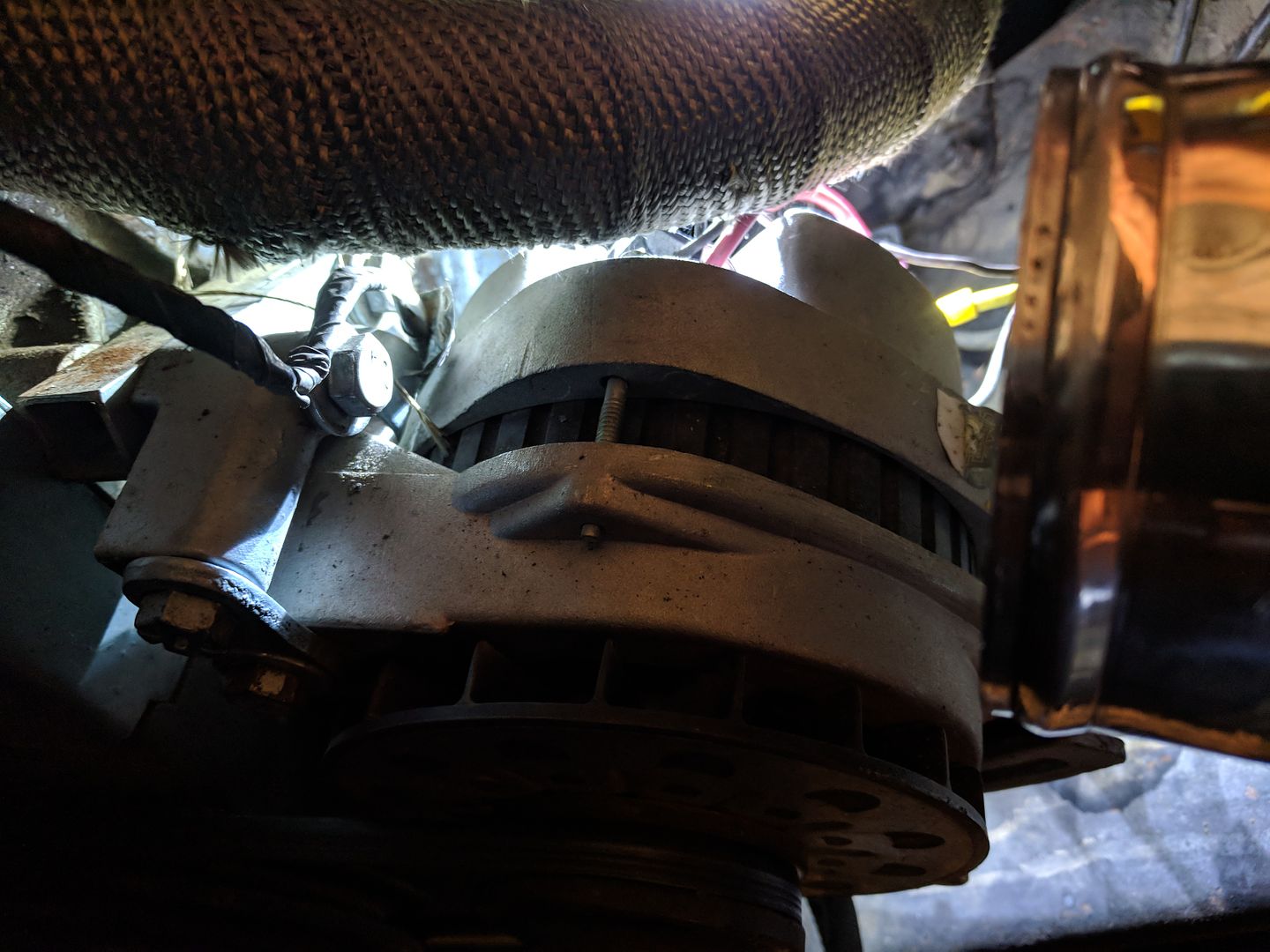

However, there is only about 1/8" clearance between it and the alternator. I have a 3/4" spacer on the alternator that I think I can remove as well as use a shorter belt to pull it down and away.

Then I finished wrapping the exhaust. If I have time I'll make some tin heat shields as well. Thermal management I think will be important.

- Likes 1

Leave a comment:

-

Thanks Jim!

As the deadline for Drag Week marches ever closer getting more things checked off the list.

Bolted up the trailer hitch. Only took about 20 minutes and went smoothly. Now I need to re-pack the trailer wheel bearings and do the trailer wiring.

Hiding my questionable welds, I've painted the engine bay exhaust parts in flat black and have started to put thermal wrapping on them. I didn't have long enough ties for both pipes so zip ties are standing in until I pick some up today.

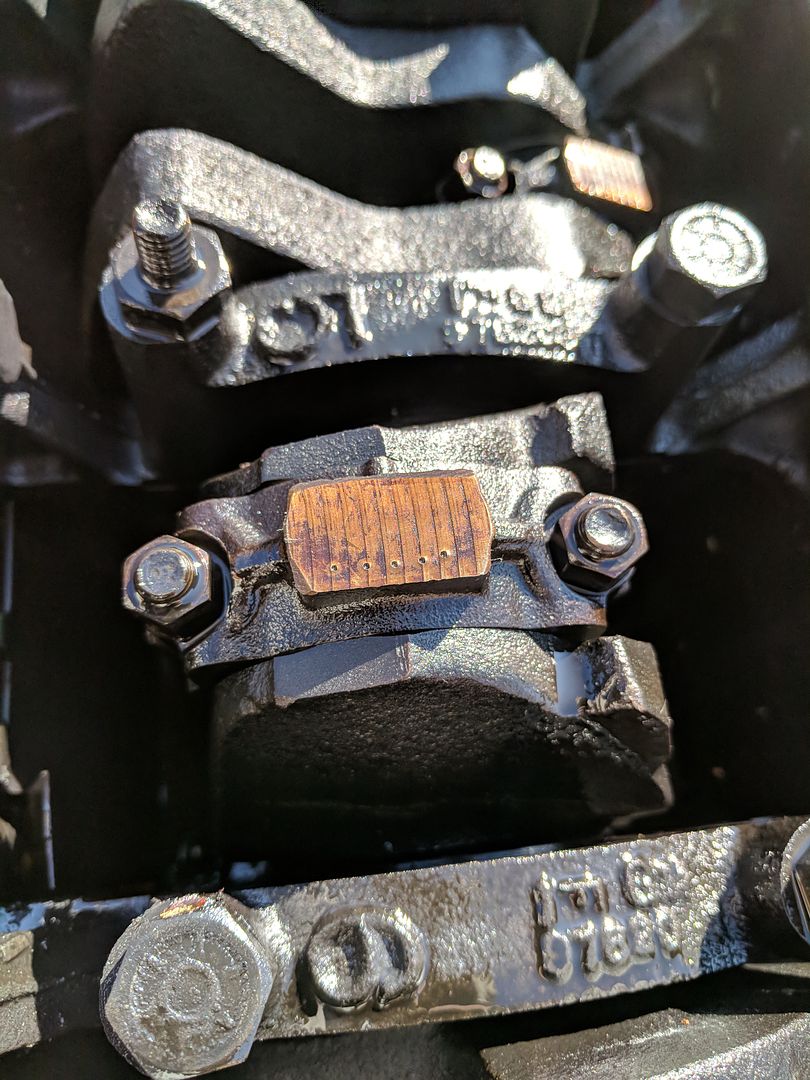

Then because my good engine will not be out of the machine shop in time I looked around at my stash of engines and had two options. One is a 230 short block that still shows cross hatching on the cylinder walls and the other an un-opened 250. A 250 head on the 230 short block would put the compression in the 7's, so I pulled the oil pan off the 250 for a peek.

Looked clean enough. If the chevy rebuild orange wasn't obvious enough it had markings on the rods to indicate a rebuild at some point.

But things went downhill from there. Pulled the head and the pistons all had a bunch of trash on them. So I vacuumed it out, sprayed a bit of WD40 around the cylinder walls and gave the crank a turn, and it turned easily, and other than looking well used the cylinder walls looked surprisingly decent. So flipped it back over to check bearing clearances.

I pulled all the mains and they all showed copper, with the #1 main being a little rough, but figured I may be able to polish it up for a short term engine. Plasti-gaged them and the clearances were pretty consistent 0.004", which is out of spec but all the bearings were worn too. Then I moved on to the rods, and thats when I found #1 was completely trashed. Rocked loosely on the journal. The journal was just scar'd enough that even I wouldn't try to polish it at home and run it. The good news is it looks like all the bearings were standard size so the crank is salvagable for future use. Also the bearings are all dated 11-77, so its been a long time since it was rebuilt. I checked the clearance on two of the other rods and they too show copper and came in at 0.004".

So my plan is now to use the engine that is already in the Firebird. I am a bit concerned about the oil pressure so I'm going to double check it with another gauge on it to verify the reading and probably run a very thick VR1 oil. Good news is it just free'd up time to work on the trailer. Plan on doing the battery disconnect switch, yanking the intake/exhaust manifolds off the car and finish wrapping the exhaust today.

Leave a comment:

-

It's like the Gonzo of the automotive world....weirdo.

Seriously tho, I am looking forward to seeing how it performs! Good luck!

Leave a comment:

-

Been busy. Finished welding up the exhaust! Welded all the pipes! The challenge was finding a place that I could put the wastegate that would pull from both tubes. Planning on painting and heat wrapping it all today.

The exhaust pipe coming out of the wastegate isn't welded on, I'll make a final one in a day or two. After Drag Week I'll probably work on plumbing it into the 4" exhaust. I tried to preserve the twin scroll exhaust plumbing as best I could, including running a divider plate to the wastegate valve face. its not a tight seal, but better than nothing. There seemed to be some flex in my turbo mount once I added more downpipe to it, so I welded two pieces of angle iron to the support to be very sure it won't break on me.

Took an intake tube to a weld shop to install the BOV flange and intake air temperature sensor bung.

I had ordered a custom trailer hitch from U-haul on August 2nd with the hope it'd show up with enough time to install it. Their website says it can take 20-45 days... Called U-haul last Monday for a status update and the guy said it was scheduled to ship September 14, which is too late for Drag Week. I told him I was hoping to have it by the end of the month, he said he'd see what he could do. Then last night (Wednesday) it showed up! I mocked it up this morning and looks like it's going to be a perfect fit. it mounts to the license plate bracket, so will sit more flush once I really install it. So relieved, while at the same time now I have to get the trailer ready too! (You can see in the background where I added an exhaust hanger on the 4" stretch of exhaust pipe to take weight off the turbo mount)

- Likes 1

Leave a comment:

-

Last night I got every thing but the T4 flange welded together. Going to do that and work on adding the wastegate tonight...

Leave a comment:

Leave a comment: