Announcement

Collapse

No announcement yet.

The Silver Buick's 1969 Firebird OHC six project.

Collapse

X

-

Excellent work! Hope you have a great week with quarter miletimes better than you hope for.

Leave a comment:

-

Or just quit posting pictures of it. Not like anyone could see it in the car =P

Picked up a Drag Week trailer for $120. Need to put new wood down, change the trailer plug to one my vehicles use and for prudence change the wheel bearings. Came with a spare tire in one of the boxes. Now I need to get a trailer hitch on the car!!

Not to mention it came with this!

Leave a comment:

-

If you want people to stop hassling you about the surge tank, just grab some electrical tape and attach a small clock to it.

- Likes 2

Leave a comment:

-

Wow, haven't updated this in a while.

The engine has been in machine shop jail for longer than its supposed to have been... but the rebuilt transmission made it back to me! I'm working on all the other details as time allows.

I finally finished the battery relocation to the trunk and got the car fired up and moving. The low pressure fuel pump promptly quit on me, but I've since changed it out. Moved on to changing out the body bushings and adding subframe connectors.

A big thing is new headers that clear everything. I've got the rear collector welded up, and am working on the front merge but only have it mocked up so far. I need to cut the holes in the primary pipe and then weld the tubes on. I've since lost my EZ-up to the wind :'( Didn't have it tied down well enough. It's served me well since 2011.

Don't look too closely at my welding!

Moved the car into the garage to start the transmission swap. It's nice working on concrete again! I've removed the 2004-r and have started the process of installing the new 4L60e. The LS versions of the transmissions have funny spacing between the torque converter and bellhousing mating surface, so have been working through those issues. Might put it in tonight...

Once the transmission is in, I will go back to focusing on the headers. With the transmission in, I can bring the car to Drag Week in naturally aspirated trim, with the headers finished, I can bring it with the turbo. With or without a new short block. I may be taking a few days off work to get this all done. The machine shop said today it's being bored and decked. The crankshaft is done. They will need to do honing, cut valve reliefs, and make a small spacer to let me use a Chevy 250 SFI flex plate. I was going to make a new wiring harness but do not think I have the time, so will simply change out the injector pigtails with the new ones for the new injectors.

For the turbo engine particularly, I need to re-do my fuel system. I am plumbing -8 fragola fuel line in and running a return line from the fuel rail, which currently I do not. I plan on going back to the "pipe" style surge canister, but will weld it shut instead of screw on caps and no brass fittings. Should look a lot more acceptable! lol

- Likes 4

Leave a comment:

-

I love exhaust dumps for the track. How about getting a removable plate to cap off the bottom of the 4" down pipe the t into the side of the 4" with the 3.5"

Leave a comment:

-

I've got a DIYautotune relay board in the Skylark engine bay with that same connector on it since 2009, and the MS3/3X harness with that plug since 2013, no issues. So I bought a couple for the Firebird and they have been working since the beginning of 2014. Probably could put some dielectric grease in them for extra protection, but I haven't.

I thought I had a better picture of the Skylark's, but this is the injector and coil pack harness plug before I put the covers on.

Makes it pretty easy to pull the engine when the harness stays on it.

Leave a comment:

-

You know i searched high and low for a good option to make my whole EFI harness disconnect. I never once thought about using the same connectors that are on the ECU lol.

I think you are golden on the exhaust I wouldn't sweat the 3" being that far back.

- Likes 1

Leave a comment:

-

If you can stay 4" to the axle, you'll be golden.

Keep it as big as you can, as long as you can...

...Then, pick a punchline, ('That's what she said', 'I hear that a lot', 'Whaddya mean another four feet', 'That extra inch really matters') or make up your own!Last edited by AndyB; June 21, 2018, 07:51 AM.

- Likes 1

Leave a comment:

-

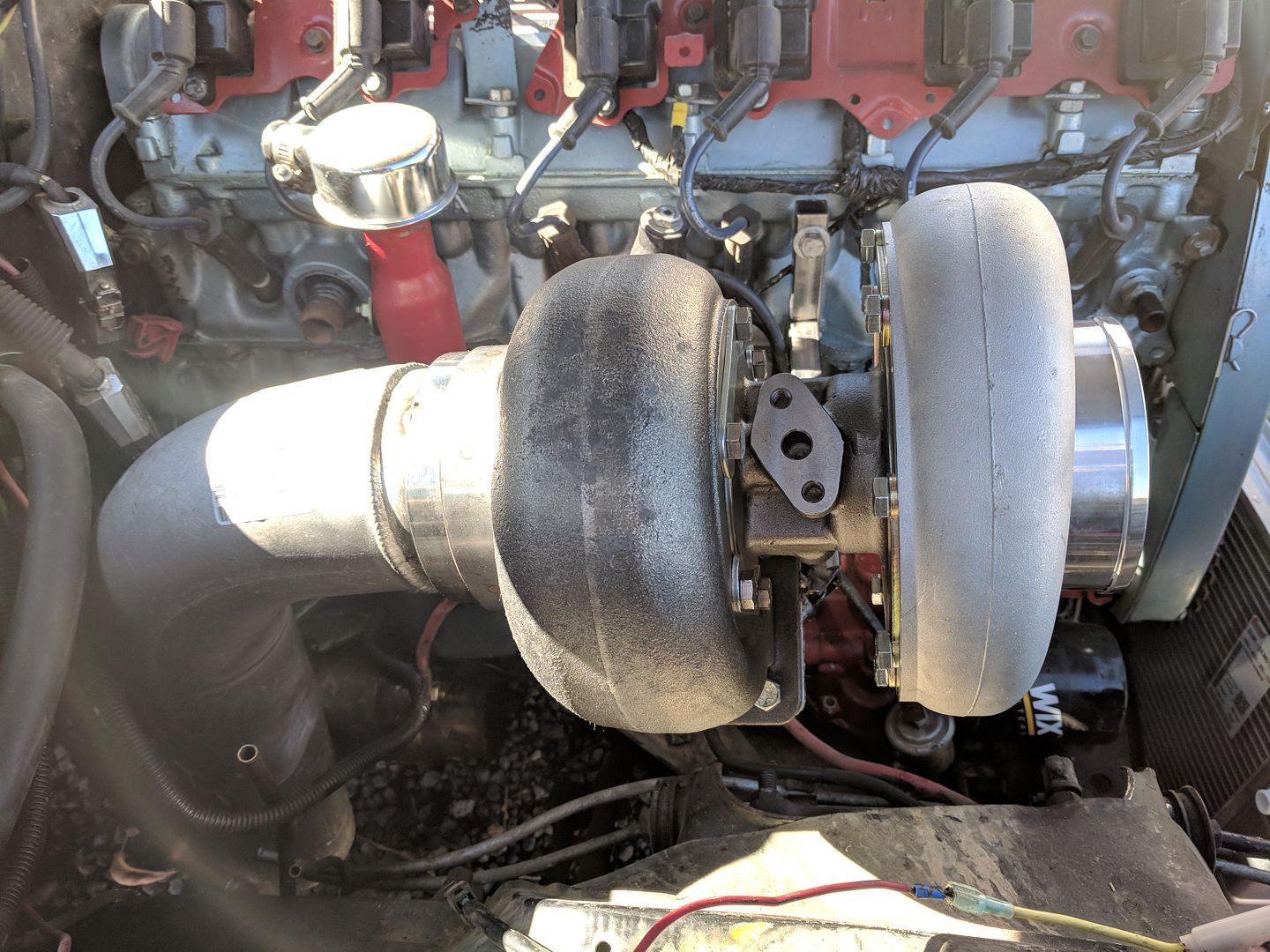

I don't think I had posted some of the exhaust pictures. I've made a few small changes since these pictures that pull the exhaust a bit more away from the firewall.

I took about an inch off the exhaust at the turbo flange end. Cut it at the back side of the welded seem and re-tacked it to the flange.

I need to re-make the transcooler lines.

Again, it's about an inch further forward now.

Last edited by TheSilverBuick; June 20, 2018, 07:18 PM.

Last edited by TheSilverBuick; June 20, 2018, 07:18 PM.

Leave a comment:

-

The 4" downpipe is definitely happening. Not going to run a muffler at this time, at least not until post Drag Week. The engine is pretty low compression so I'm letting the turbo "muffle", then take it out to the bumper so I really don't have to hear it if it is a tad loud

The bottle neck will be the 3" tail pipe over the rear axle. So it will be stepping down, but rather that is 2 feet behind the turbo before it turns 45º to go under the car, or several feet back near the rear axle.

Leave a comment:

-

If you go with the 4" downpipe and it goes back to the middle of the car, the cost difference shouldn't make that much difference between 3.0 and 3.5" for the last half. Doublecheck muffler cost and availability also though, because that'll be the other major headache of the exhaust.

Leave a comment:

-

Well I am shooting for the 600HP range

As I've always heard it, the bigger the pressure differential between the drive side and exhaust side the better it works. No exhaust has the least amount of pressure, big exhaust the next best. Because the turbine smooths out all the cylinder pulses there is less exhaust scavenging that can be achieved from pipe sizing, etc.

I looked up the exhaust pipe costs, now I'm not sure what I want any more =P Ground clearance of course should be a concern.

$31 - 3.0"

$32 - 3.5"

$44 - 4.0"

Leave a comment:

-

I have 3" (stock) exhaust on Truck (the Dodge/Cummins). Edge told me that bigger exhaust would do nothing until I was at least in the 600 HP range - and they could have sold me an exhaust system. Not sure if that rule of thumb applies to Otto cycle or not but it IS a place to start.

DanLast edited by DanStokes; June 19, 2018, 07:57 AM.

Leave a comment:

-

If you have concerns on the exhaust just get one of those valves that open under boost. You can cruise nice and quite and the exhaust will open up when under boost. I'm with you though I don't think you would have much of a power drop with your current plan.

Leave a comment:

Leave a comment: