Saw a bunch of these motors at a wrecking yard, thought they were cool.. Ohhh maybe 20 years ago..

Then pretty much never heard much of them till this.. Interesting..

Then yesterday saw an ad for a Firebird that had one of these in it and a 4 speed up in Tumwater (near SBG). Bottom was rotted to nothing!

$5K! Some people! Claims to have the better 230 over the 250..

Which makes me wonder if he knows the OHC engines came in 2 sizes or thought the 250 is chevy..

Watching this only cuz it is interesting..

Announcement

Collapse

No announcement yet.

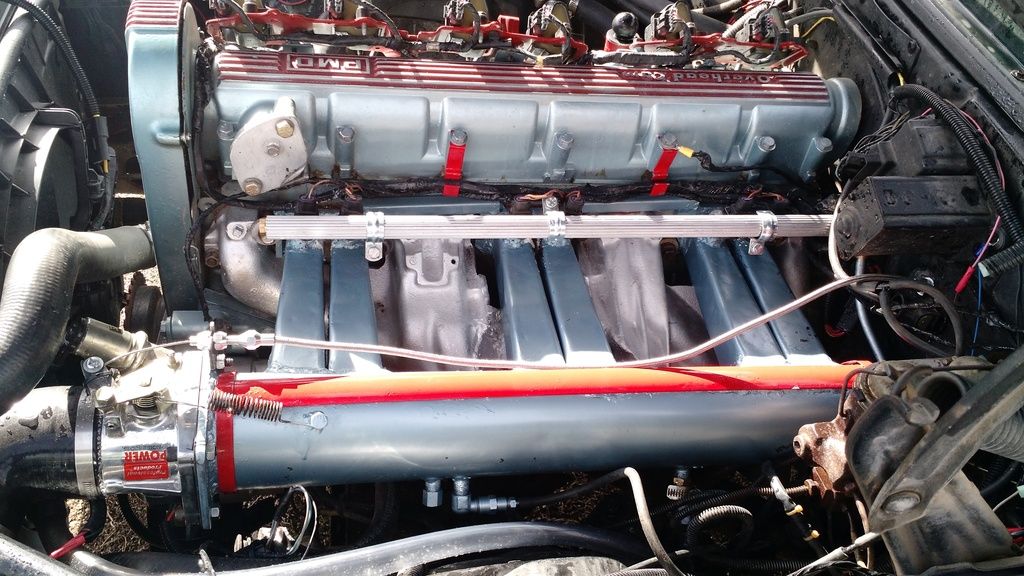

The Silver Buick's 1969 Firebird OHC six project.

Collapse

X

-

Yup, should be able to go right over the water pump. Will decide later if I'll just pull from the fender well or put another hole in the core support.

I just talked to a local machine shop, if I can get the short block in this week he said 3-4 week's turn around time, maybe less. Should be pretty straight forward on the block work.

Leave a comment:

-

looks like it also gives you room for a cold air intake. nice work!

- Likes 1

Leave a comment:

-

Got a lot done this weekend, gives me hope on having a drag week ready car before the end of August.

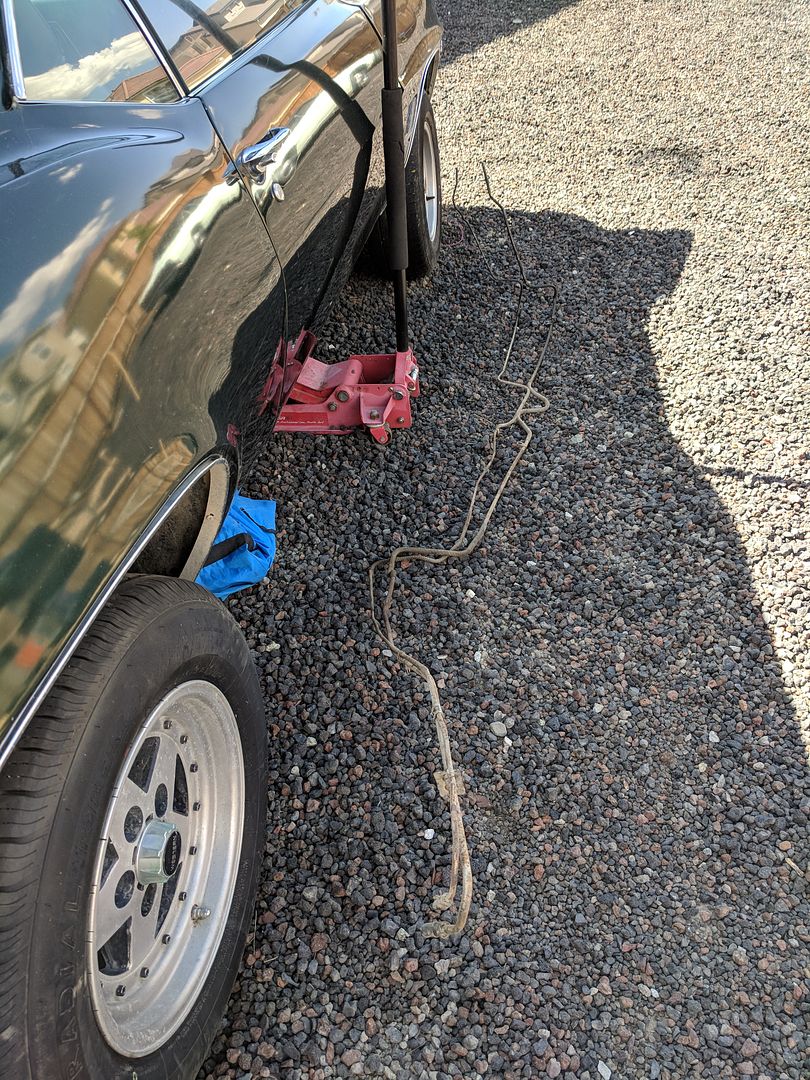

So I bit the bullet and installed the battery in the trunk. Full box, cables out the back and down through the floor of the trunk. I still need to install a power disconnect switch and heavy duty fuse, but the 1 gauge positive cable is ran to the front with brackets holding it in place. The kit came with a short 24" ground cable, so I picked up some 4 gauge ground cable until I get 1 gauge down the road.

I figured since I have moved the fuel supply to the driver's side, I could remove the stock fuel lines on the passenger side and run the power cables more or less along the path the fuel lines used to go.

I've got three bolts holding it to the floor.

This should clear all the exhaust pipes going to and from the turbo.

With the battery tray free'd up, I welded a bracket to the tray to hold the water pump. I looked at options of just making a bracket to the frame or core support, but it was definitely simpler to attach it to the tray. I will probably use that space for power distribution, move the fuse panel from the fender well to the tray.

Sits about 2" higher than the stock pump did, but I do not expect any issues as long as I'm not low on coolant.

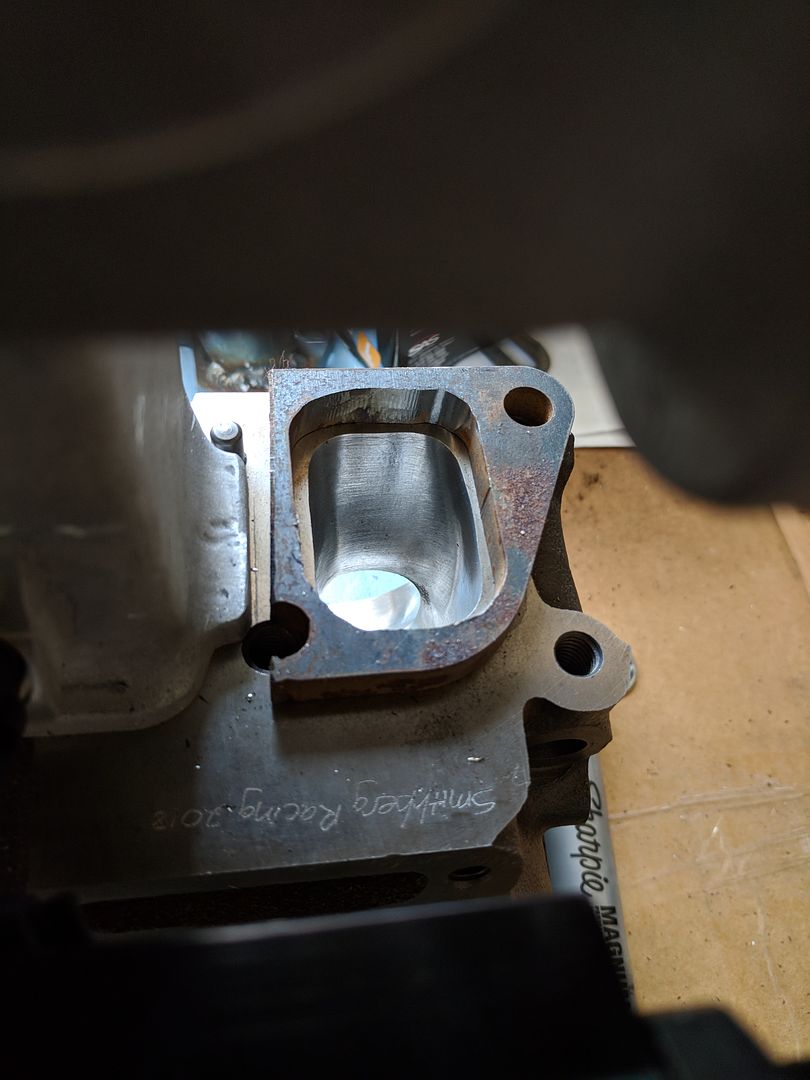

I also started on the flanges for the new set of headers. The flanges I have were just a bit on the small side, and the end ones needed to be squared up. So I took a grinder to them and started opening them up.

I'm hoping this week to get a machine shop lined up for the short block and either during the week or over next weekend get a transmission boxed up to ship to a builder that has done a few other Drag Week'er transmissions, so my hope is high the 4L60e will survive behind my little L6.

- Likes 1

Leave a comment:

-

I haven't made any progress on this because I've been trying to figure out a solution to mounting the electric water pump and have been getting no where. So I'm biting the bullet and relocating the battery to the trunk and putting the water pump where the battery sat. I need to get one of my 4L60e's shipped out for a professional build as time is ticking!

Leave a comment:

-

Unfortunately not as much progress in the last month as I'd hoped to have. A combination of bad weather on the weekends and other priorities coming up. I did bend some aluminum strap metal for the upper intercooler support. I need to get some matching bolts to the core support, but otherwise it is finished. I also hole-sawed the core support and ran the cold side plumbing through it. I need one more 90º coupler and then to trim down one of the pipes to get it in the right spot for the new intake. Boy does it tempt me to get a carb hat on it and hook up the turbo to this engine, lol!

I need to figure out where to fit the Mezier water pump and then I can go back to at least driving the car. It's a monster of a unit compared to the small Craigs-Davies unit I had been using, and the hot side plumbing to the turbo plus 4" exhaust are now occupying the space the water pump once did. I think I'm really going to be putting the "remote" into remote water pump.

I need to get some new header flanges cut to start on the bigger header tubes, that actually clear the new intake manifold, but this can be done outside the car.

- Likes 3

Leave a comment:

-

Do some real fancy plumbing to keep my reverse flow cooling system. There is certainly room for an offset, the interference is like a 1/2" or so, and honestly a decent welder could probably just notch a stock housing as the simplest solution.

With the stock intake, the challenge was clearing the throttle body with a straight rail, because laying over the rail enough to clear the housing would cause it to intersect the throttle body. I experimented with two ways to get around this, and ran into trouble with the lines leaking, and the other way was injector caps, but didn't have the right kind of hose between the caps.

My home made intake had the injectors layed over enough to clear a stock thermostat housing.

With the intake Nick worked on, he probably could have layed over the injector a bit more, but he wasn't aware of the thermostat housing issue, nor was I particularly concerned about it. This is were a simple notching of a stock housing would probably work. If I get a second intake I'll take more care to have it layed over some more.

Leave a comment:

-

Izuzu or one of the like small trucks have a in hose type thermostat housing..

Wouldn't do you much good as you basically need a fancy nipple

Seeing how you said above that you do not run a thermostat..

Leave a comment:

-

Thermostat Housing / Water Neck, 1" Offset Billet Aluminum $135

Leave a comment:

Leave a comment: