Announcement

Collapse

No announcement yet.

The Silver Buick's 1969 Firebird OHC six project.

Collapse

X

Collapse

-

After work today or tomorrow I plan on putting the Firebird up on jackstands in the barn to begin the transmission pull to see what is going on inside of it. With that, right before Christmas two front rotors showed up, so I can possibly also switch out to disc brakes while it's up in the air along with swapping out the rear axle for the 8.5" with 3.42 gears and an honest limited slip rear end. While I have the front and rear brakes apart, I'm going to look at adding a hall sensor to read the back side of the wheel studs to use as a vehicle speed sensor. Should only require drilling a hole in the dust shield and adjusting a threaded sensor with two nuts holding it place...

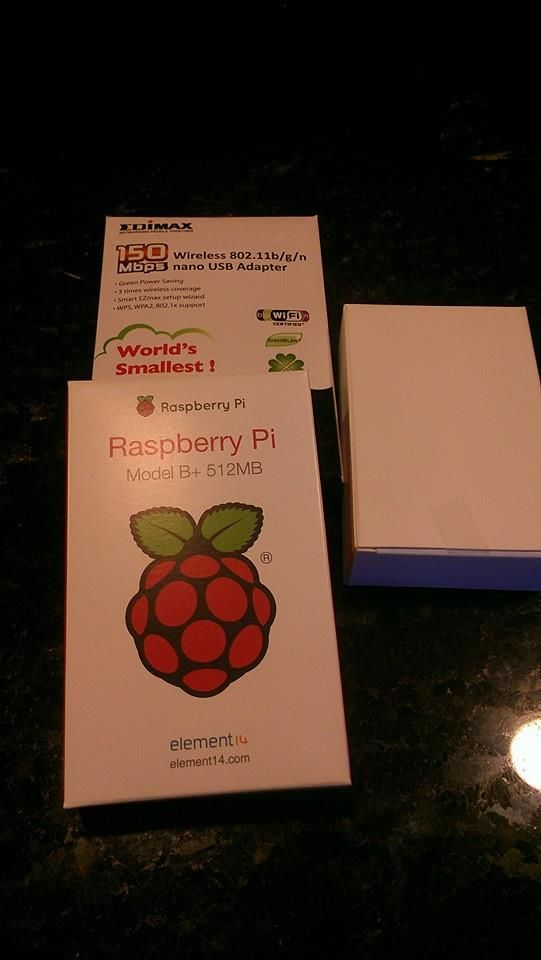

To shift gears a bit, I got a Raspberry Pi mini computer for Christmas and am going to attempt to make a digital display in the Firebird similar to what I have in the Skylark but not yet go to the extreme of replacing the dash cluster. This will be a round one so to speak. If it works out well then I will try to eventually expand to replacing the cluster with a digital display. The primary hangup is my inability to use Linux But, figure it's only a matter of time before I figure it out enough.

But, figure it's only a matter of time before I figure it out enough.

Goal one is to simply get it to start up and run Tuner Studio, from there I can expand on the idea.

What I am thinking of doing after I get it operational is getting a 7" touchscreen for it (they seem to be less than $75!?!?) and replacing the generic panel with the Arrowhead on it with a touchscreen displaying various engine vitals. Interestingly enough, when I requested quick keys to change the display layout in TunerStudio for the Skylark, the programmer also added screen swiping at that time to change display layouts when using touch screens. So "in theory" I can have various gauges on there, but simply reach over and swipe left or right to have different data show up, or gauges with different warning light thresholds, etc. And being rectangular, means a different layout than I am using in the Skylark

The panel is 2.5" by 4.5", but I don't see any issues with fitting a 7" screen back there, which I believe the dimensions are 3.9"x6.2". That would make the screen stick out approximately 3/4" a side in width and just over 3/4" top and bottom. Plenty of wiggle room. Mounting it firmly may require some creative work though.

So much to do!Escaped on a technicality.

Comment

-

Pulled the transmission out and yanked it apart today. As I suspected the friction plates were toast. I haven't seen anything else out of place. I put most the trans back together using the friction plates and steels I pulled out of the transmission when I first rebuilt it back in February or so. I haven't put the valve body back on it yet, as I want to make sure it's cleaned out for sure.

The plates I pulled out of it on the left and the "old" ones I'm re-installing on the right. In another stack the friction plates looked cooked and the steels had hot spots. I believe this to be the result from when my TCC solenoid came loose and about fell out. I'm guessing hydraulic pressure dropped dramatically.

Escaped on a technicality.

Escaped on a technicality.

Comment

-

I made sure the valve body was definitely cleaned out. I found some directions online from a shift kit that talked about removing a spring from an upshift valve (said some transmissions have it, some do not..), so I removed the spring from mine. I took the opportunity to open up two holes in the valve body plate to the next size up while I had it apart. Now it's just a filter and gasket away from ready to go back in.

Since the transmission is on hold, I pulled the 8.2" axle with 4.56 gears on a spool, for an 8.5" with 3.42 gears and a standard limited slip carrier. Haven't done anything more from this picture though. One of the metal brake lines twisted and broke on removal, so I'll replace both on the axle. I forgot to get some gear oil, so I need to go to the parts store anyways.

I spent the rest of the time looking at relocating the TV cable from the throttle body to the firewall and directly off the gas pedal. Once I heard of some folks doing this I was interested because I'm using a universal cable and its maxed out on length and will only get worse with the intake I'm building. Putting it on the Firewall takes that worry out. I measured the pull of the cable on the transmission, and found the points on the firewall to gas pedal that give the same distance. It's just a notch below where the throttle cable goes.Escaped on a technicality.

Comment

-

-

SOOOOOO what caused the early failure of the trans clutch plates????

Nice progress - you are one of very few gents I know that can rebuild an automatic transmission - and program the space shuttle through megasquirt.There's always something new to learn.

Comment

-

-

What makes you think I can rebuild an automatic transmissionOriginally posted by milner351 View PostSOOOOOO what caused the early failure of the trans clutch plates????

Nice progress - you are one of very few gents I know that can rebuild an automatic transmission - and program the space shuttle through megasquirt. Especially after this:

Especially after this:

I "suspect" when this bolt came out (and the other was loose) that pump pressure was bleeding off around the solenoid and the drop in pressure allowed the plates to slip. Its the only thing I found that I could identify as "wrong". I have had perpetual problems with the adjustable TV cable's adjuster sheath slipping and causing slack in the cable, which could be suspect, but I really don't believe the slack to be enough to cause the plate wear. I'm changing to a standard off the shelf cable and connecting it to the gas pedal to be sure though (plus the adjustable one wouldn't be long enough for me new intake anyways).

I'm certainly not afraid of diving into automatic transmissions anymore though. My skills inside of one are still certainly questionable though.

Last edited by TheSilverBuick; January 5, 2015, 01:33 PM.Escaped on a technicality.

Comment

-

slack in the TV cable will let clutches fry....it makes the valve body "think" there is less load on the transmission than there really is, so it doesn't apply as much pressure to the clutches, so they slip more than they should.My fabulous web page

"If it don't go, chrome it!" --Stroker McGurk

Comment

Comment