I guess I hadn't started a thread on this one

As many know, I got this H3 to replace the POS GTO which replaced a prior H3.... I like my H3s

I've done basically nothing to it other than wheel it a couple times.... but for SAR, I need a winch

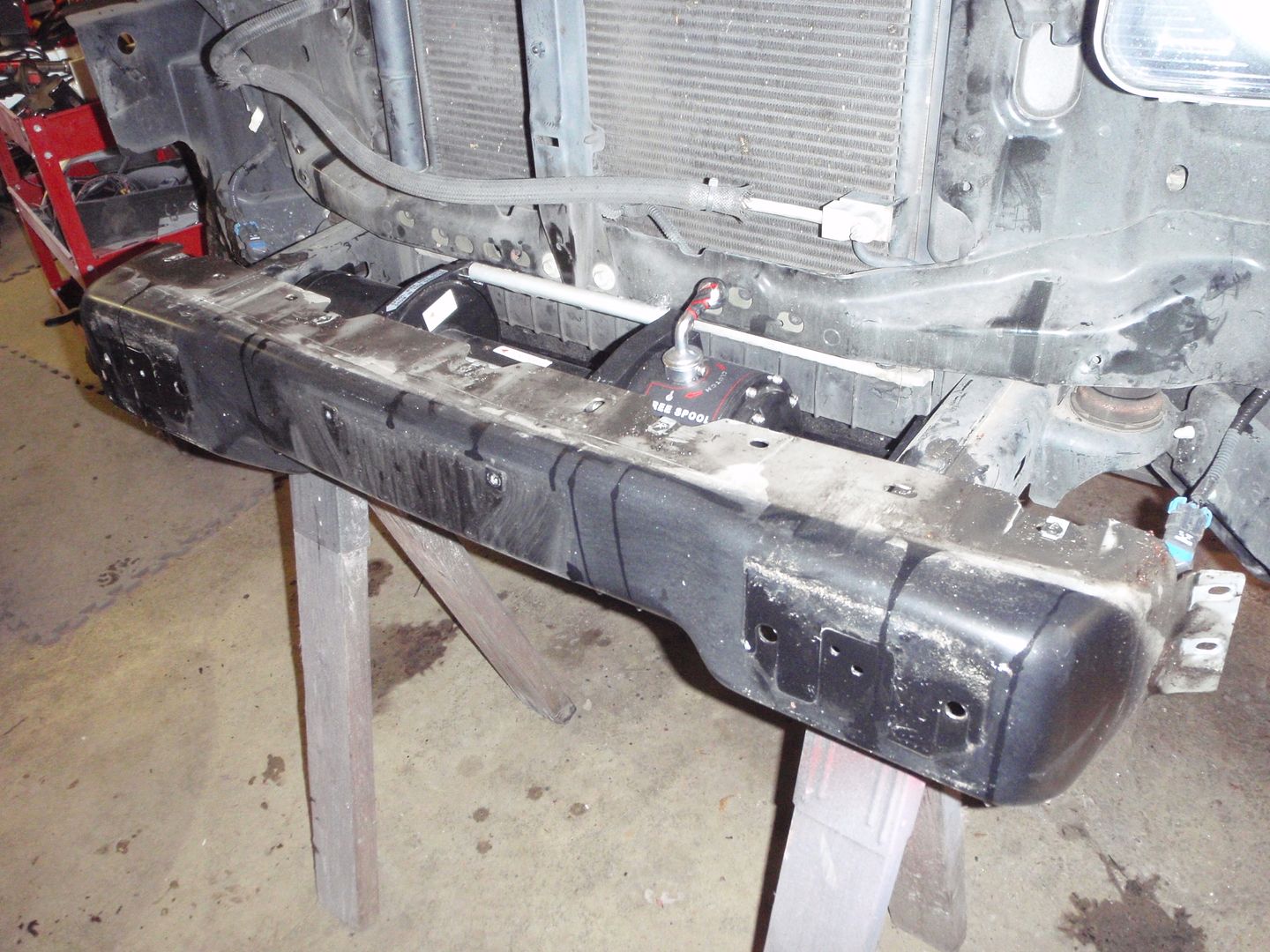

Today I basically started scoping out what I needed to do

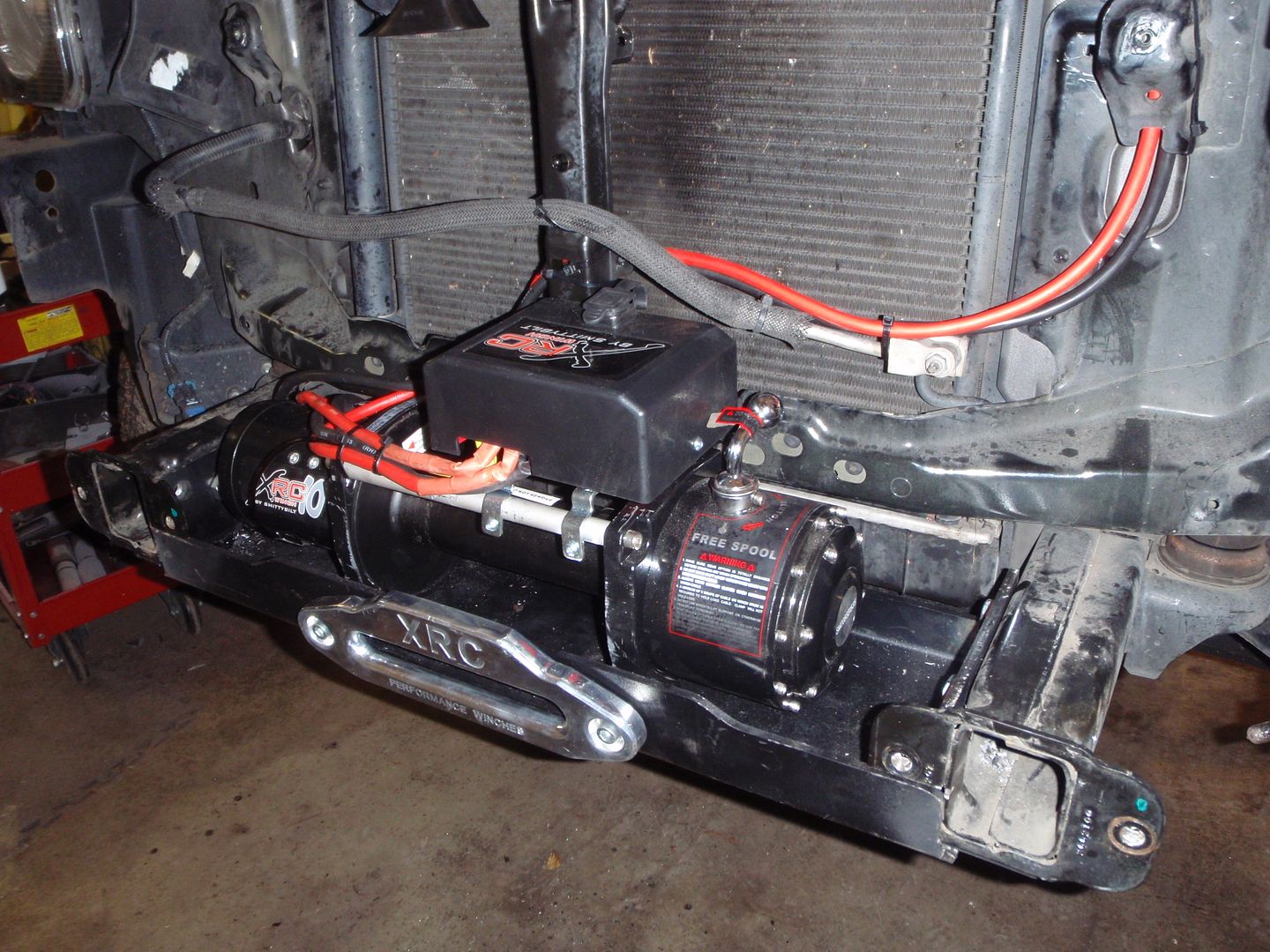

the winch

the H3

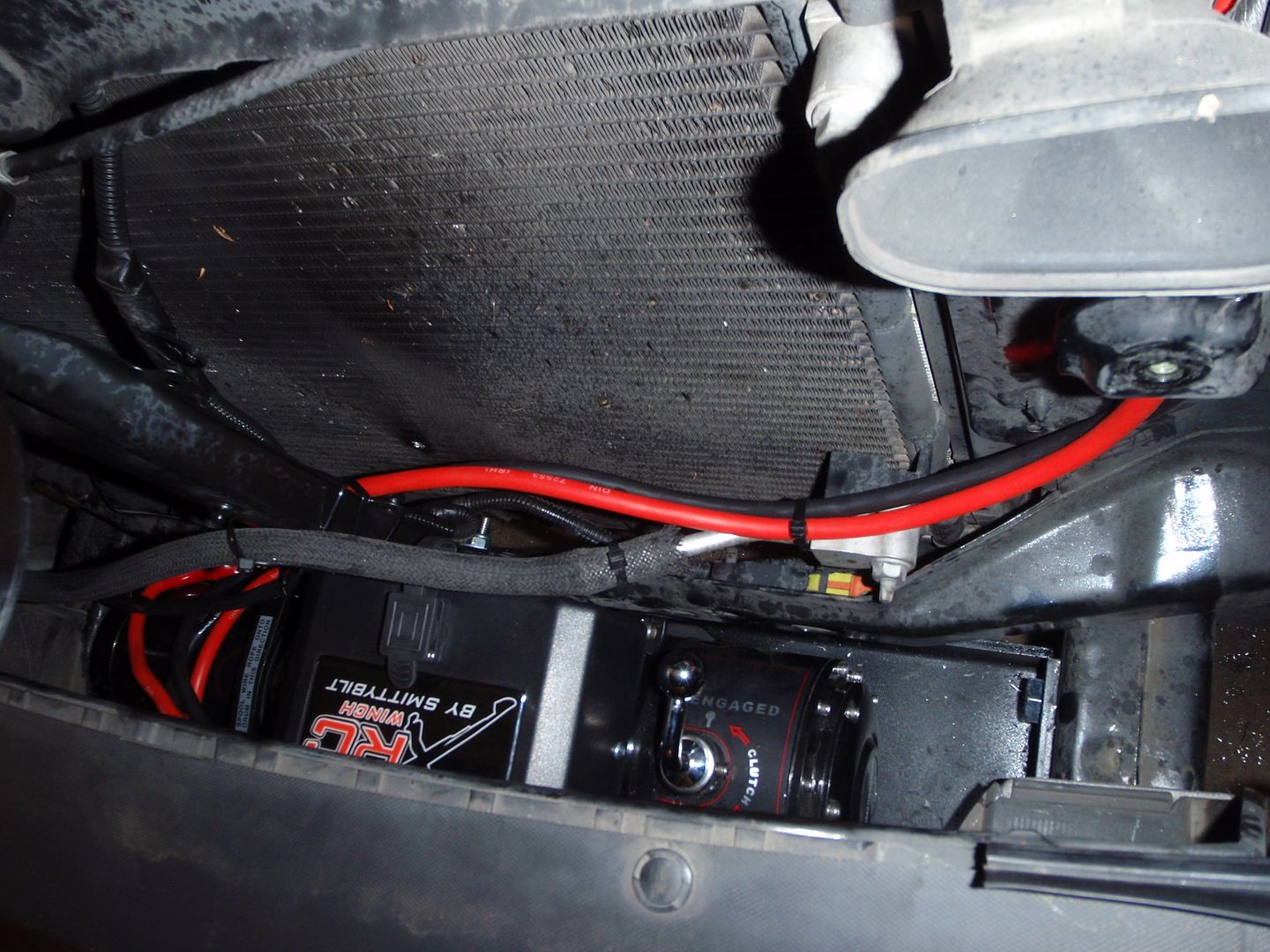

1st thought was put the winch where the plastic air intake is located..... and it may end up there, but there are issues with blocking airflow.... so I bit more searching

As many know, I got this H3 to replace the POS GTO which replaced a prior H3.... I like my H3s

I've done basically nothing to it other than wheel it a couple times.... but for SAR, I need a winch

Today I basically started scoping out what I needed to do

the winch

the H3

1st thought was put the winch where the plastic air intake is located..... and it may end up there, but there are issues with blocking airflow.... so I bit more searching

Comment