After driving the countryside for a couple weeks, Back to the grind, took delivery of the bus with the cracked hood this past Wednesday.

After removing headlights, I ground out the cracked areas, which relieved the tension and allowed the panels to lay flat again. Epoxy was used between the outer and inner layers, clamped, and let things set up.

After a couple layers added....

Left this to cure in the sun for a couple days, then back at it on Saturday.

Ground smooth and hopefully the last layer added...

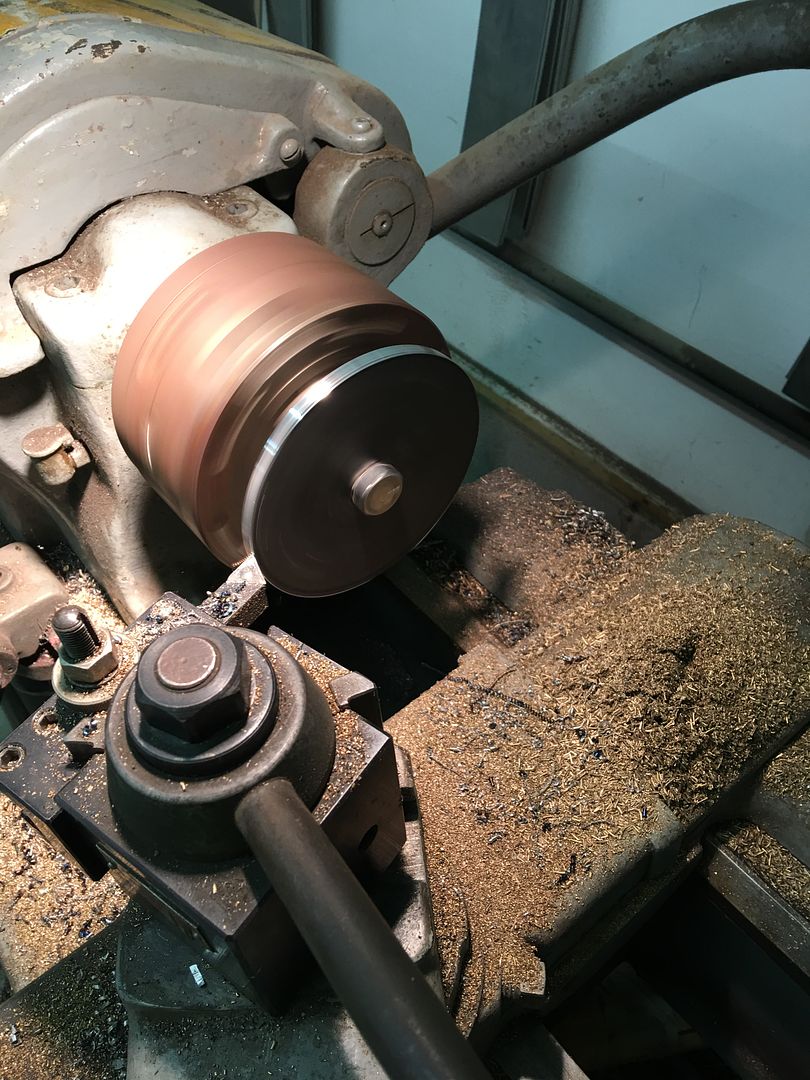

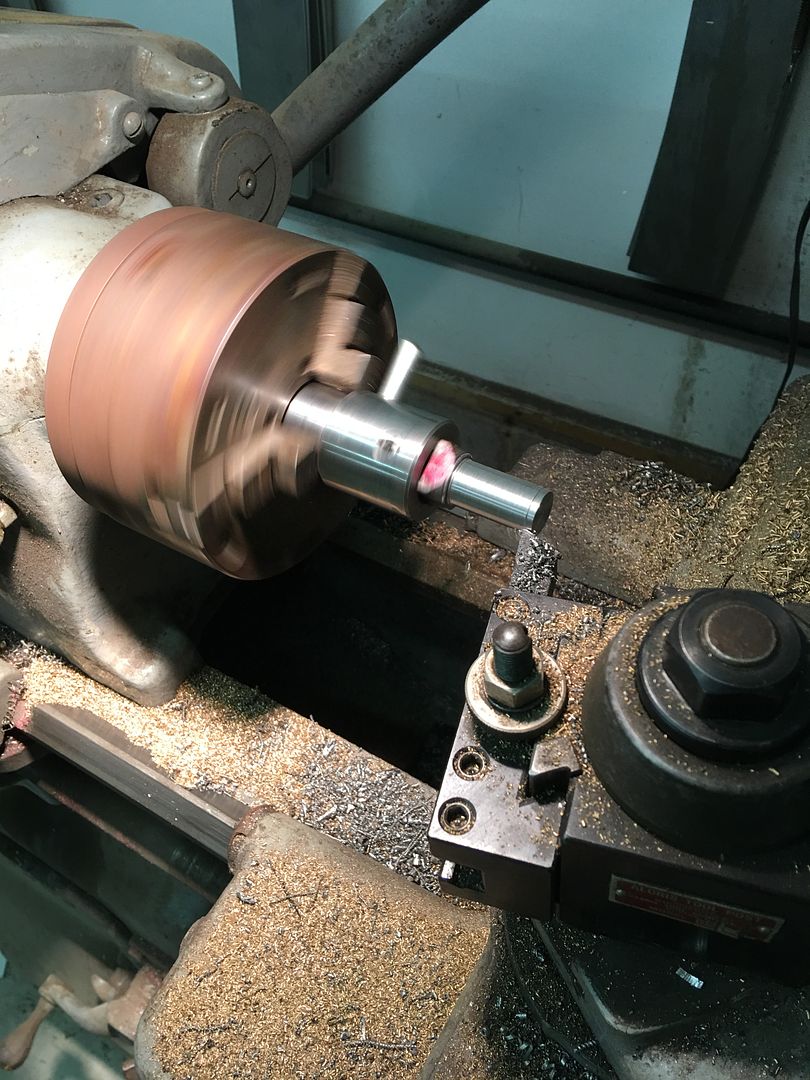

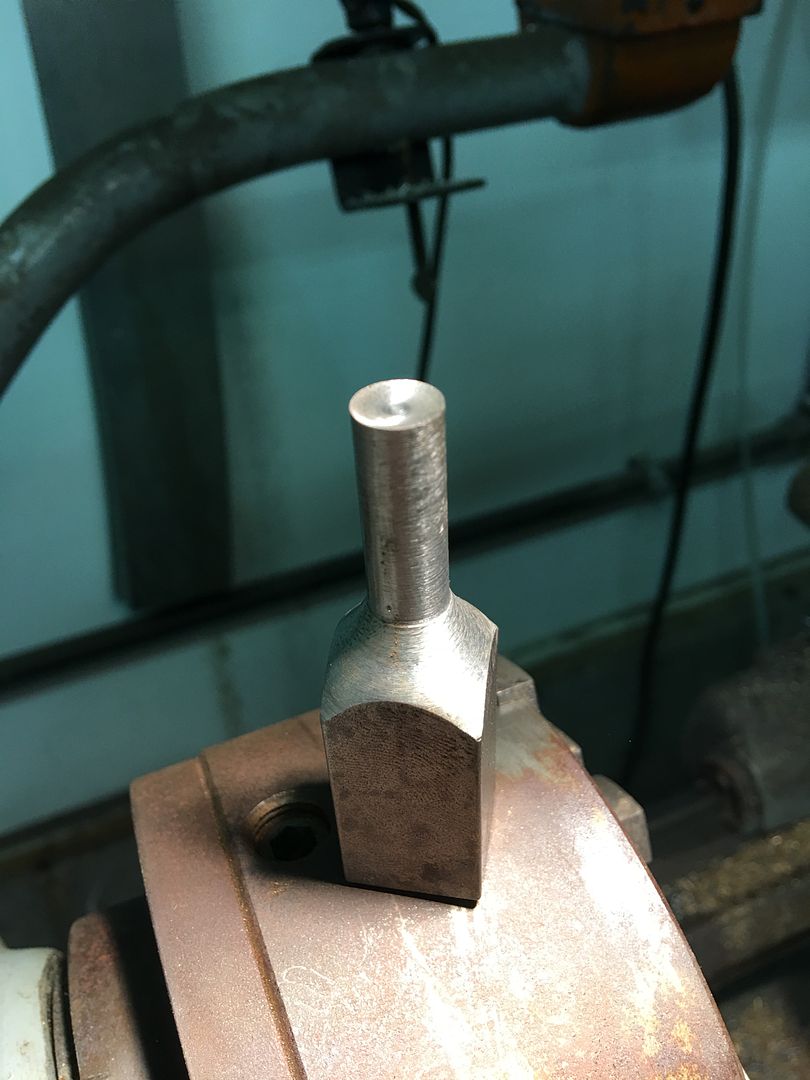

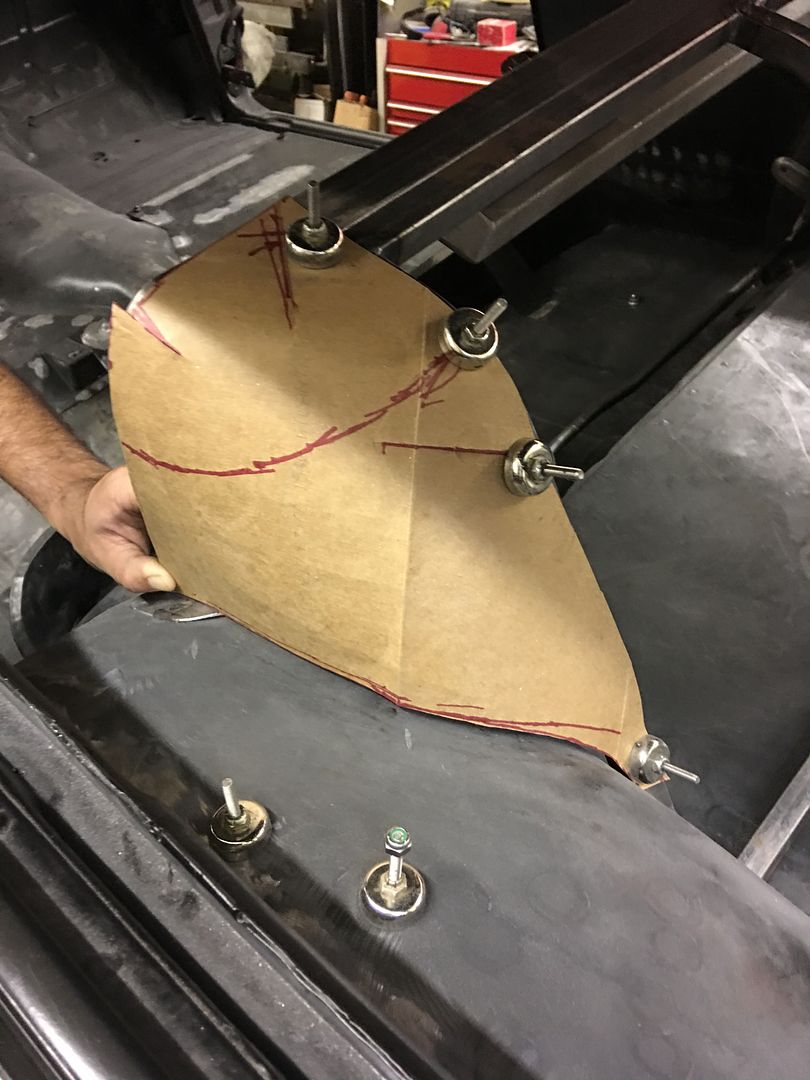

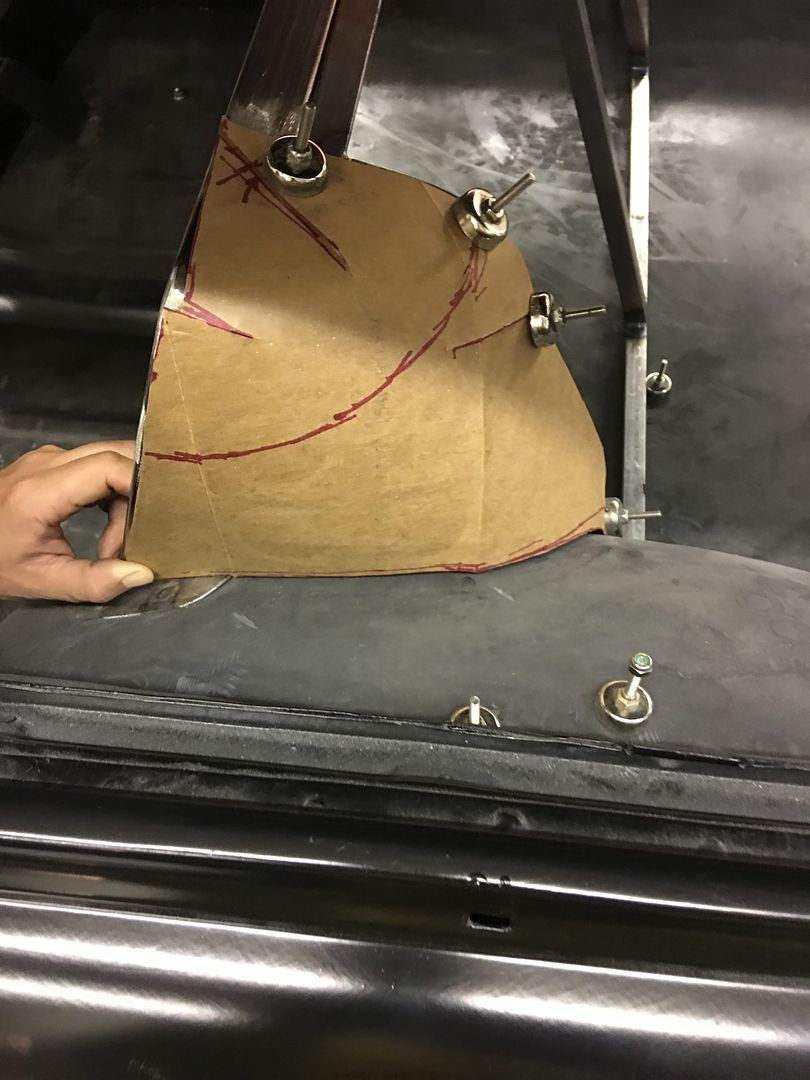

Back on the wagon, we needed to close off the back side of the rear seat.. We have some square tubing to use but needed a radius bender. The upper part of the buffer stand looks like it may work. As I've told Mike, everything is a tool..

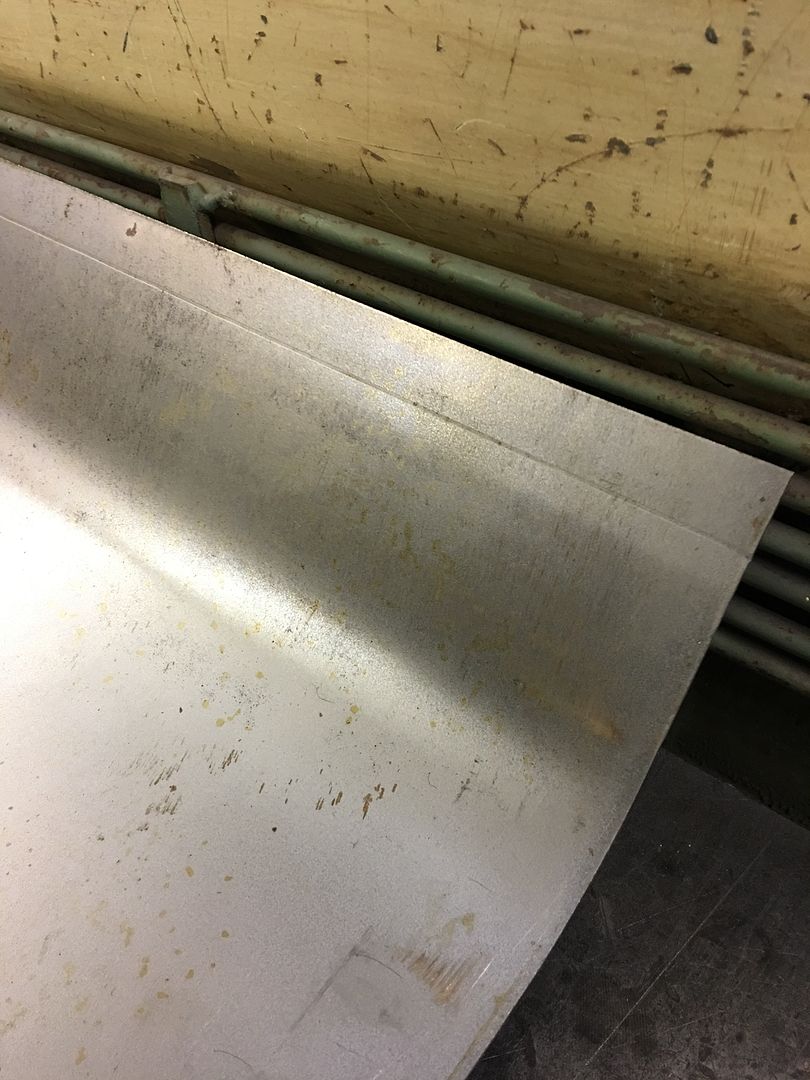

Add a welder and a piece of round stock for an anchor...

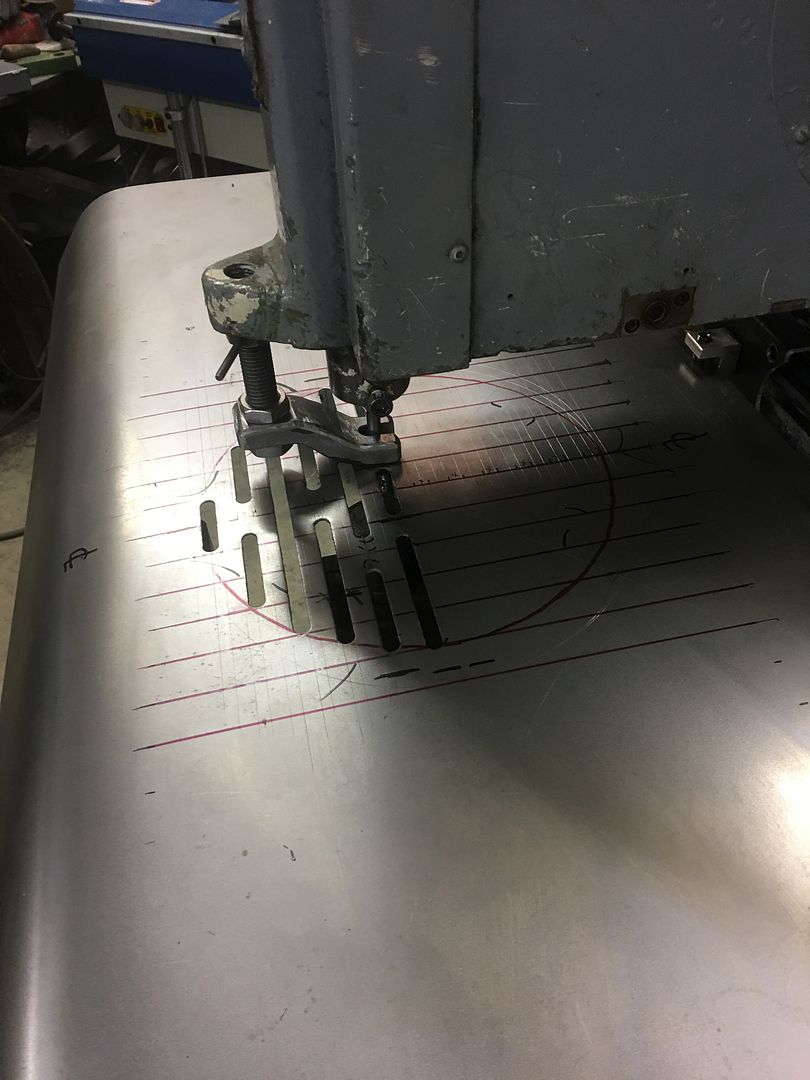

First test...

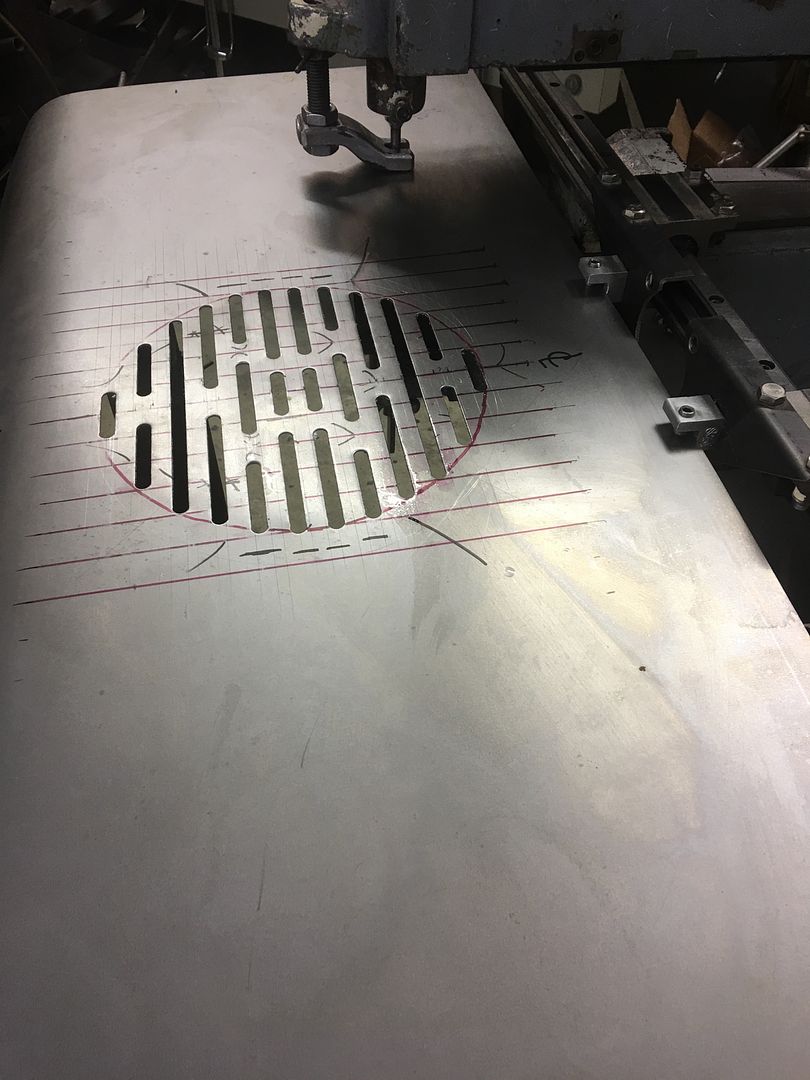

Four pieces needed...

All TIG welded together...

After removing headlights, I ground out the cracked areas, which relieved the tension and allowed the panels to lay flat again. Epoxy was used between the outer and inner layers, clamped, and let things set up.

After a couple layers added....

Left this to cure in the sun for a couple days, then back at it on Saturday.

Ground smooth and hopefully the last layer added...

Back on the wagon, we needed to close off the back side of the rear seat.. We have some square tubing to use but needed a radius bender. The upper part of the buffer stand looks like it may work. As I've told Mike, everything is a tool..

Add a welder and a piece of round stock for an anchor...

First test...

Four pieces needed...

All TIG welded together...

Comment