To be honest, I was installed some pin drive concrete anchors last July and smacked the be-jesus out of that thumb. It's been about three months that I haven't seen the remnants of that day...

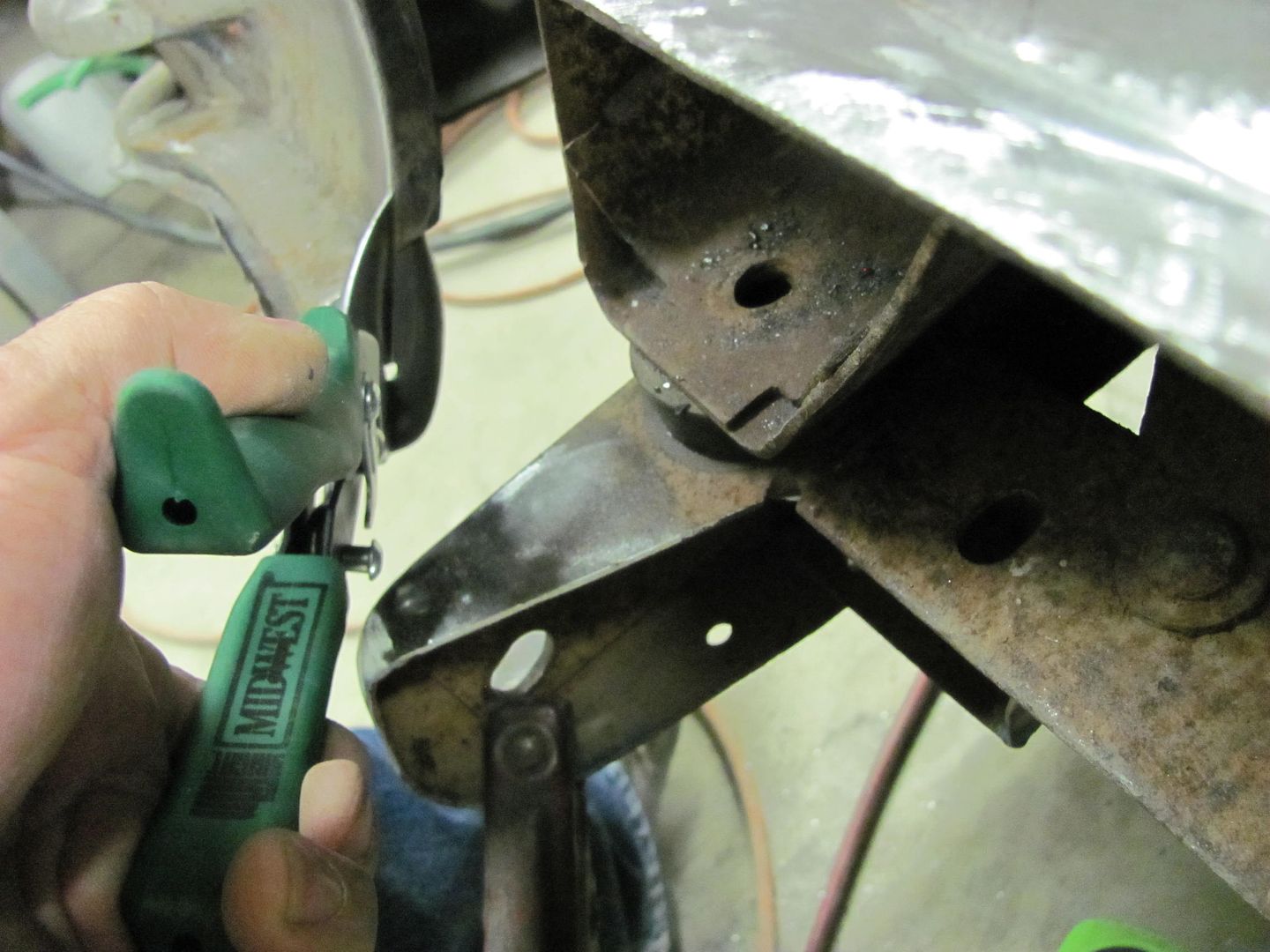

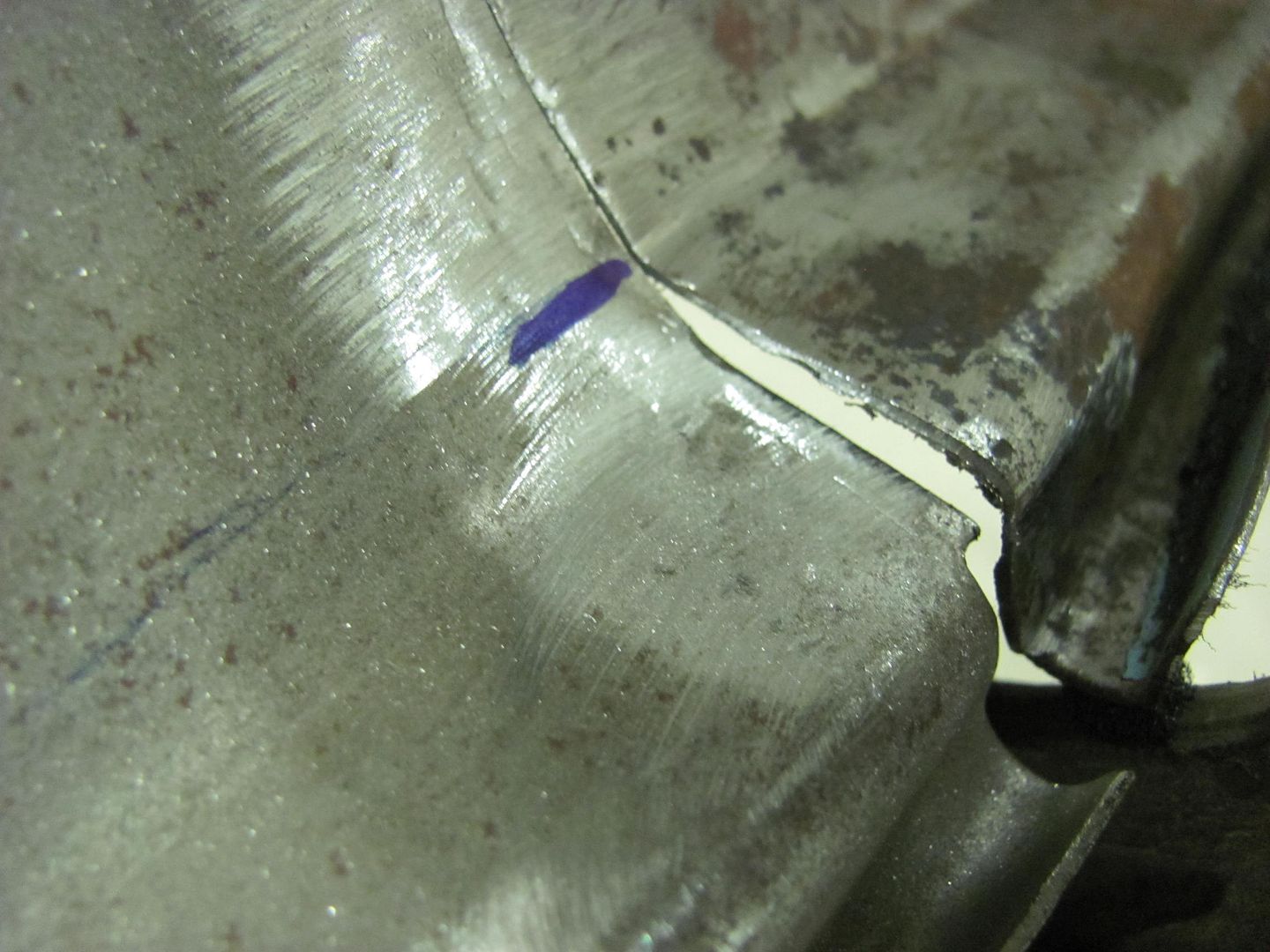

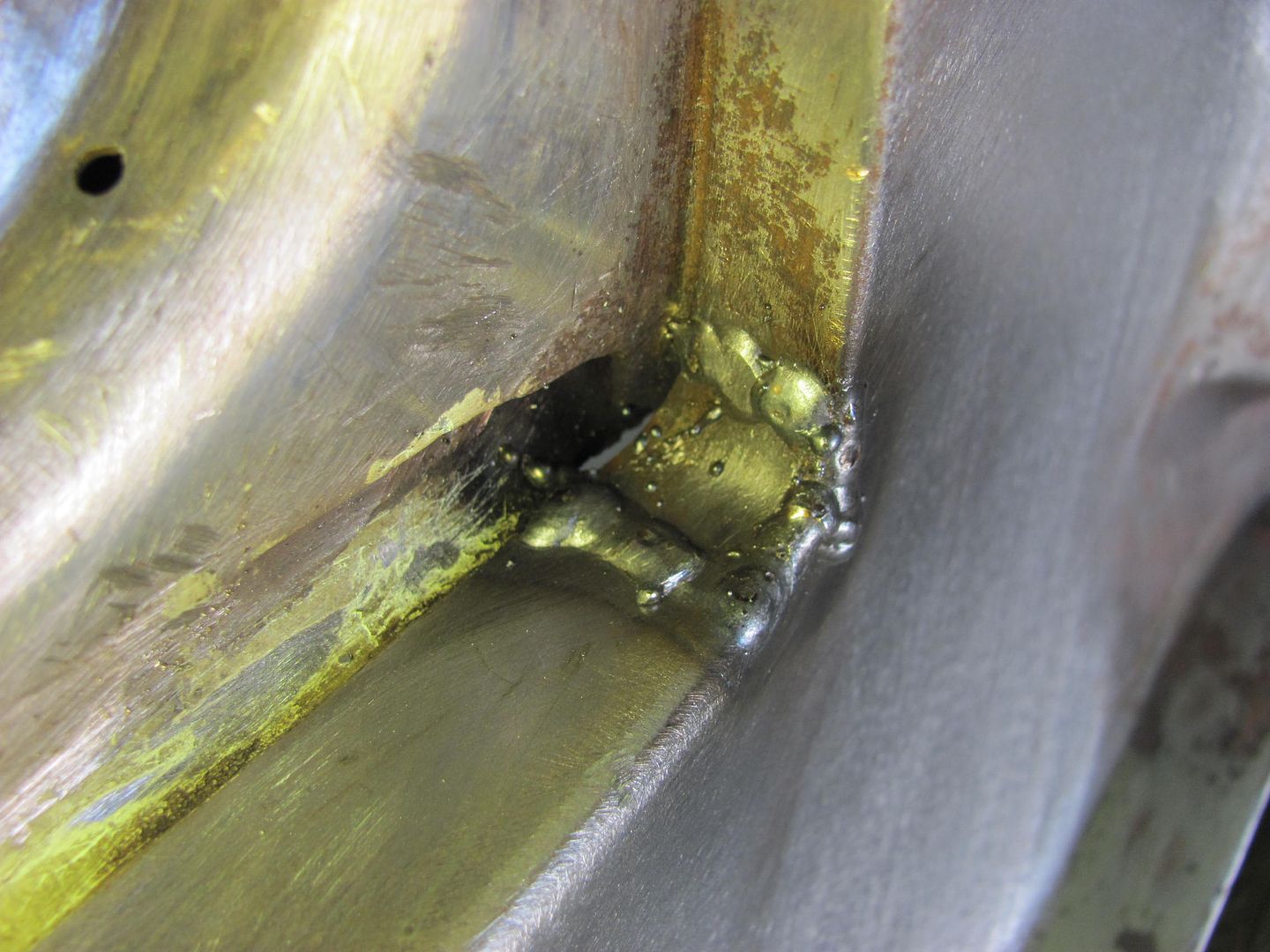

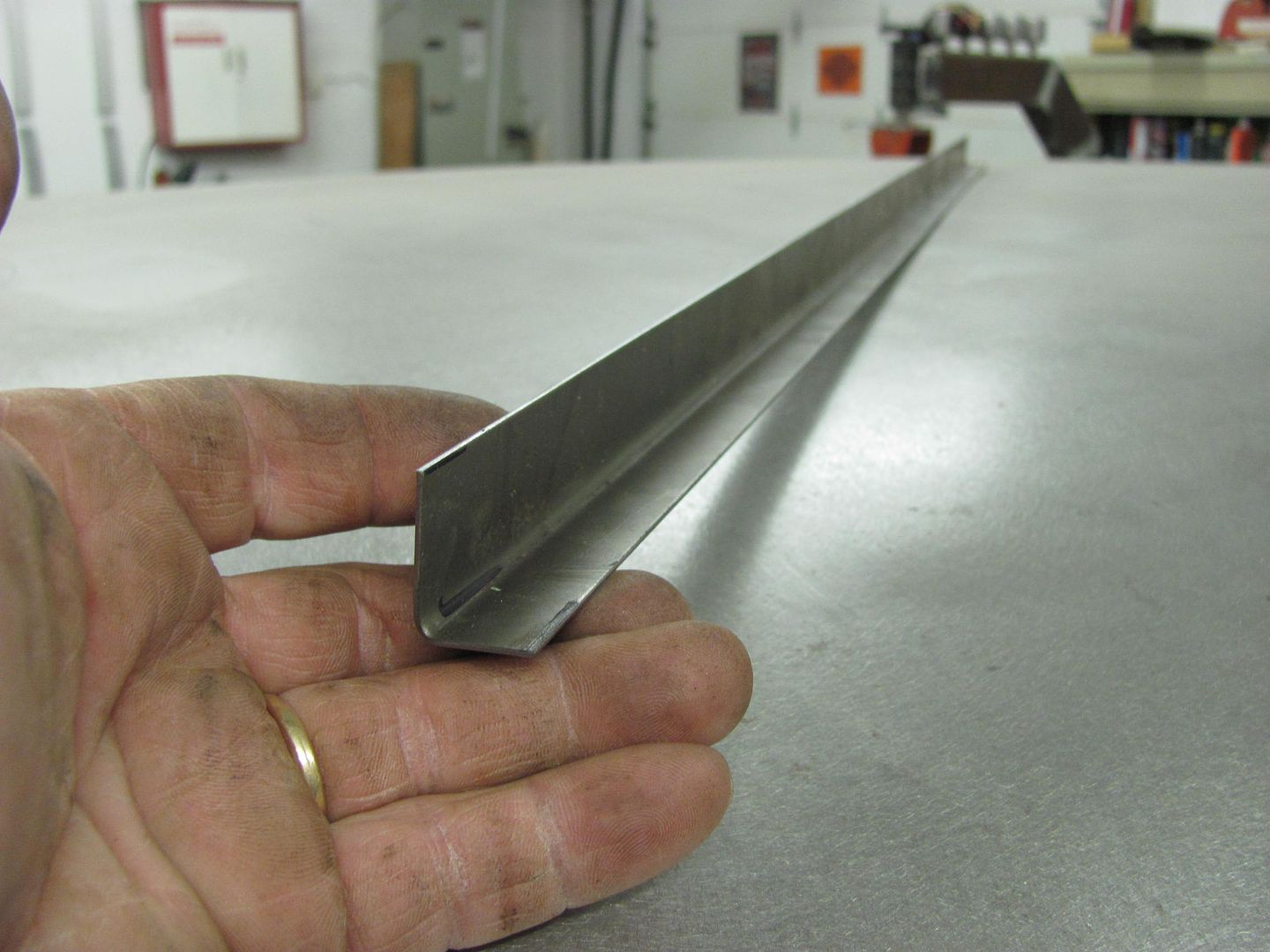

Time to finish this part up....

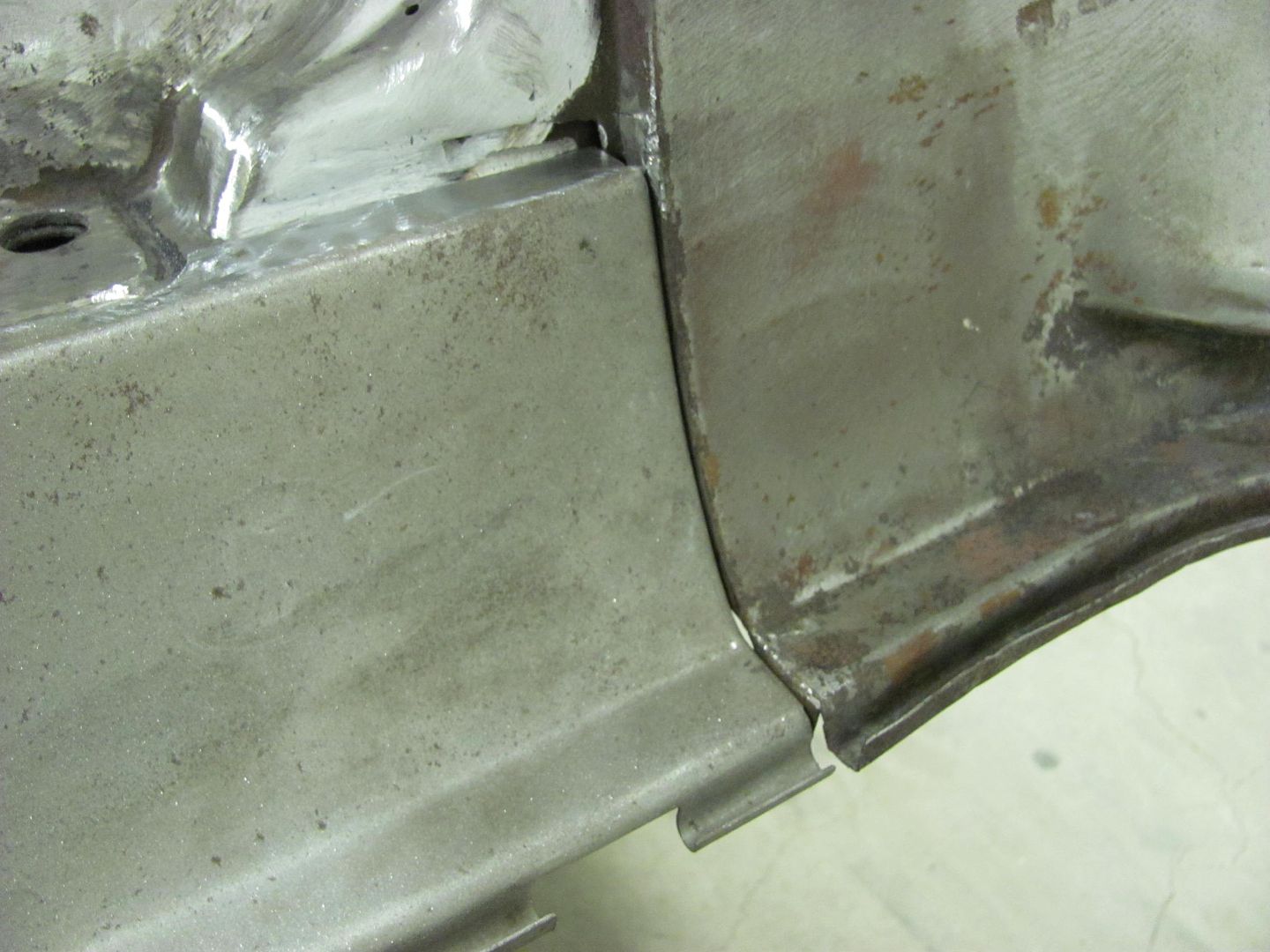

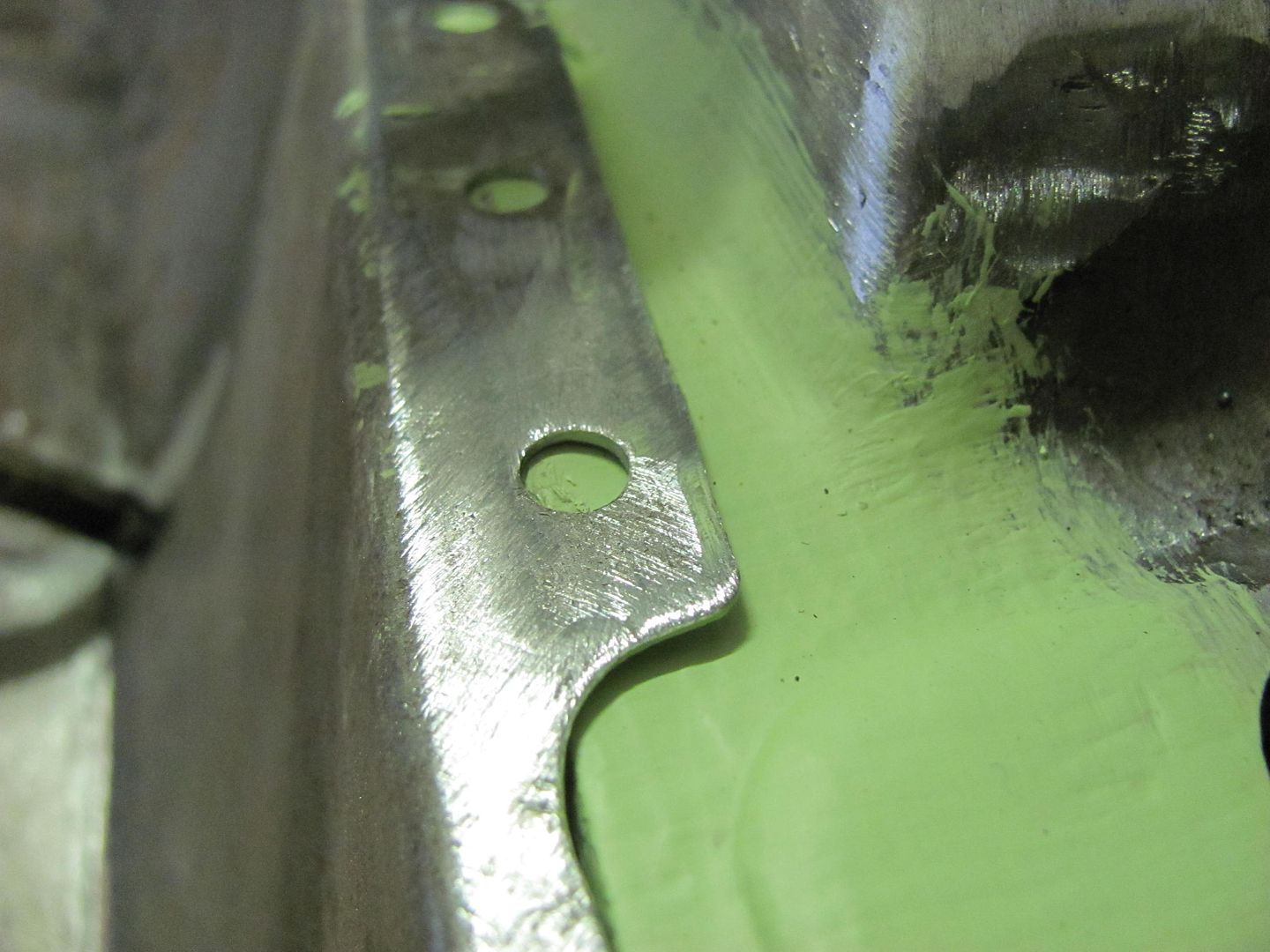

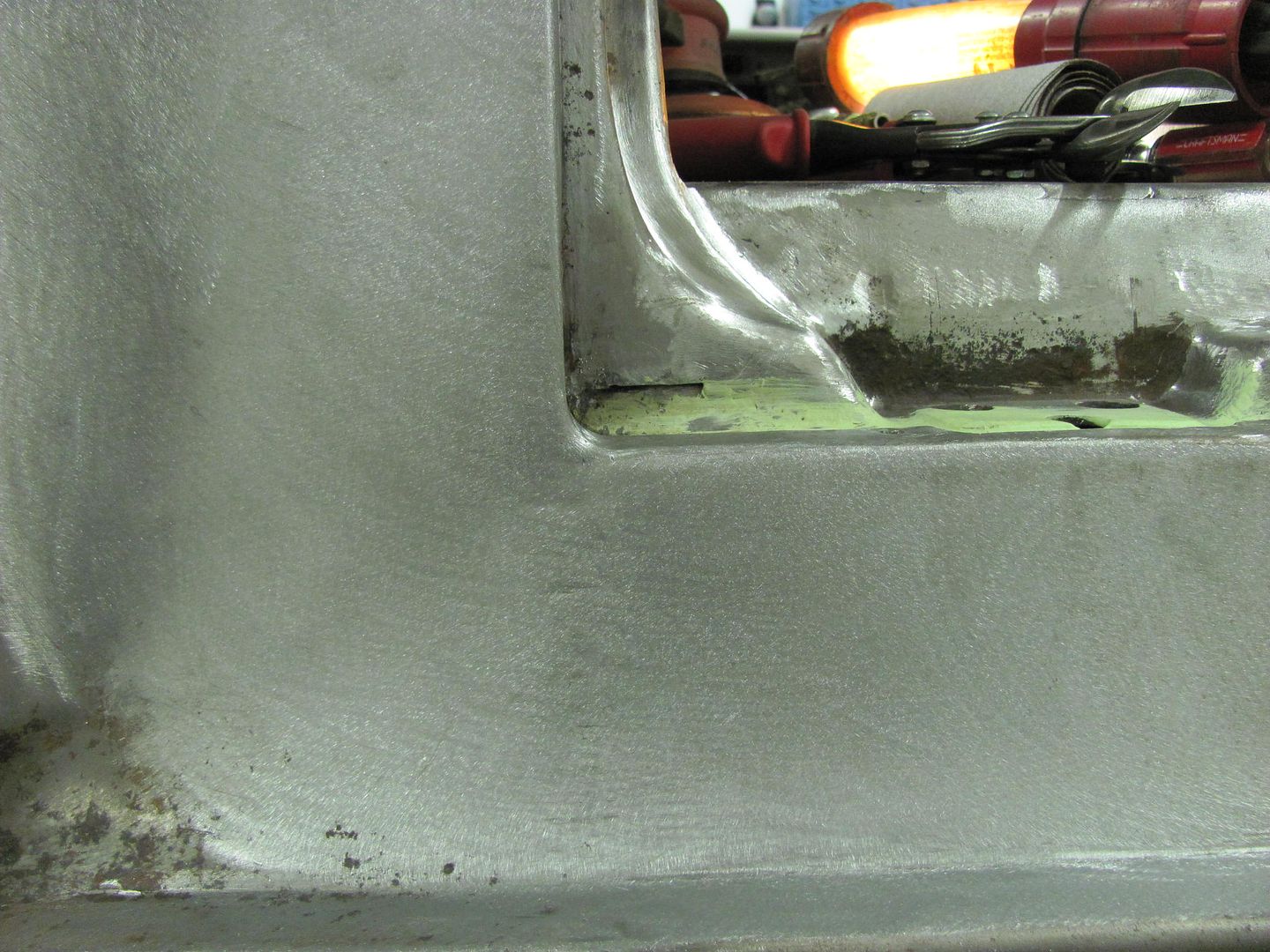

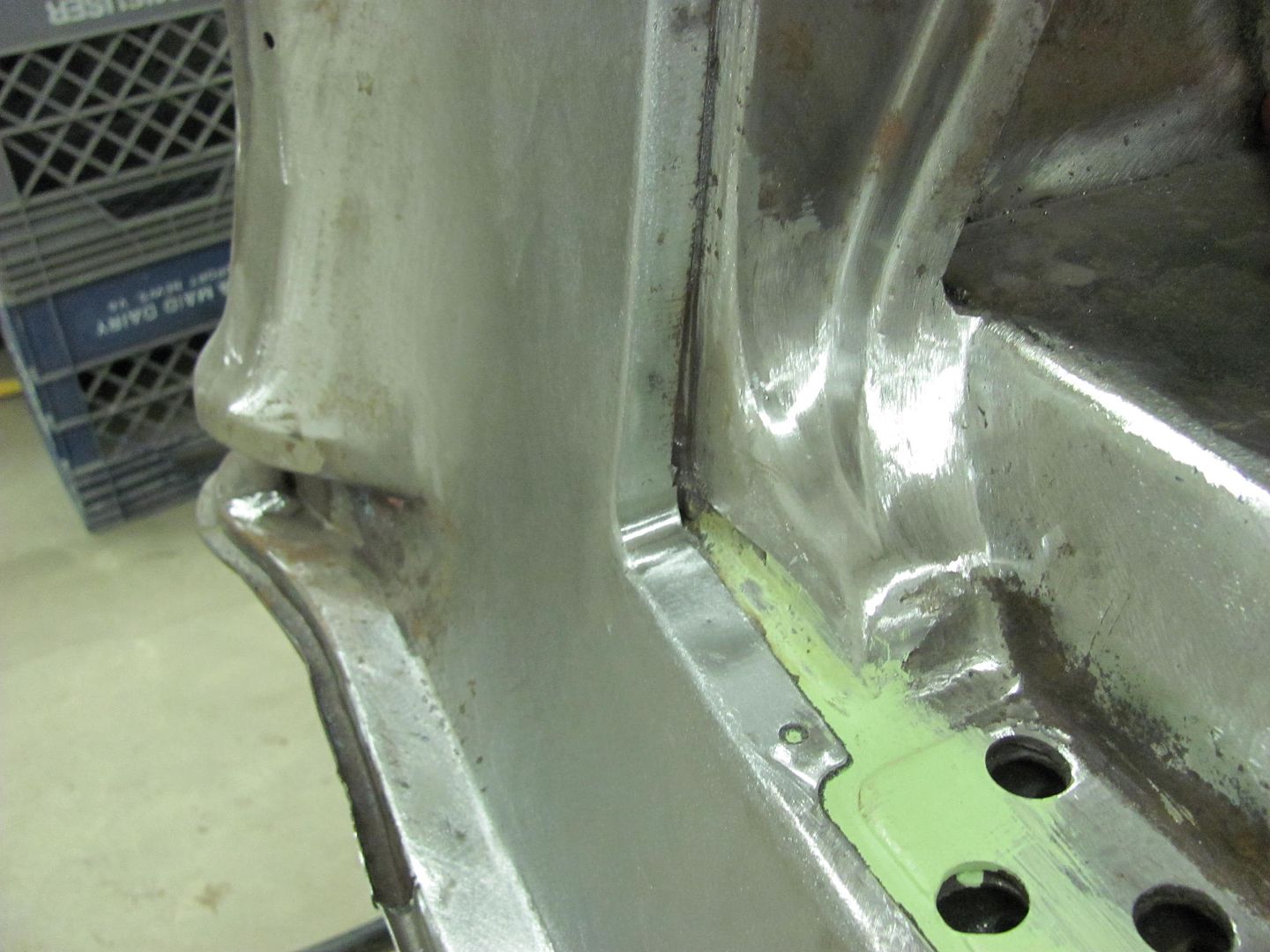

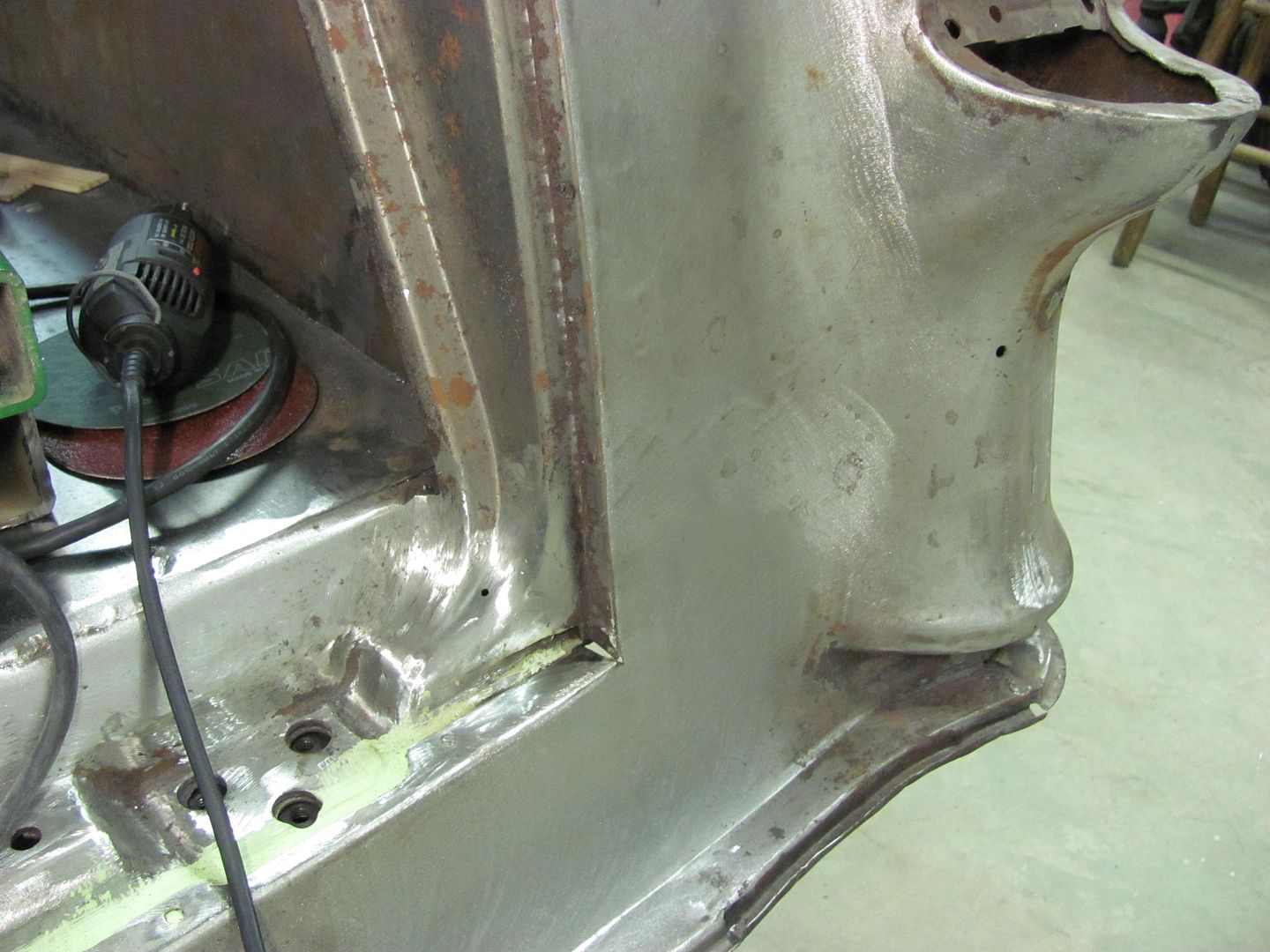

All cleaned up....

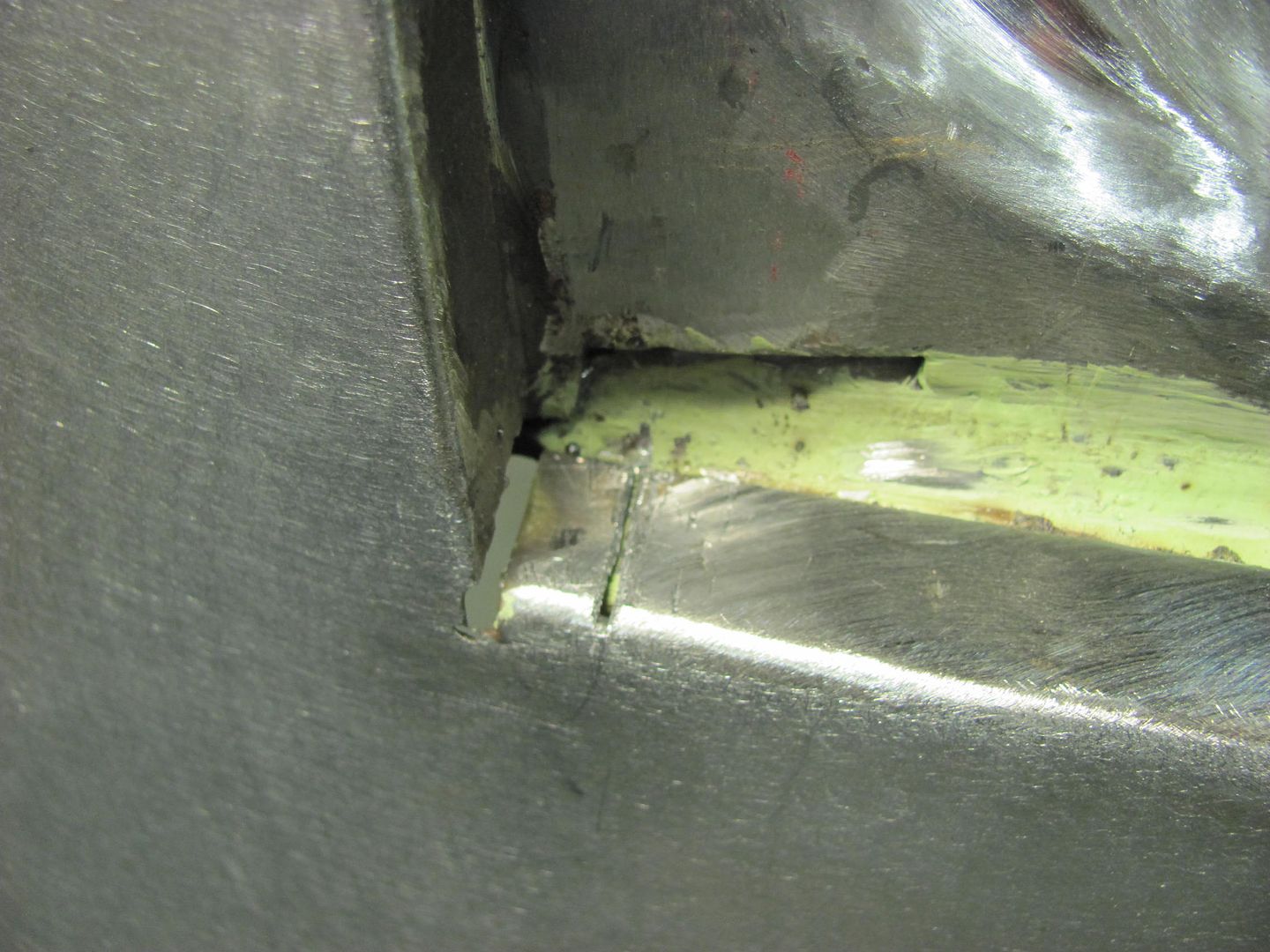

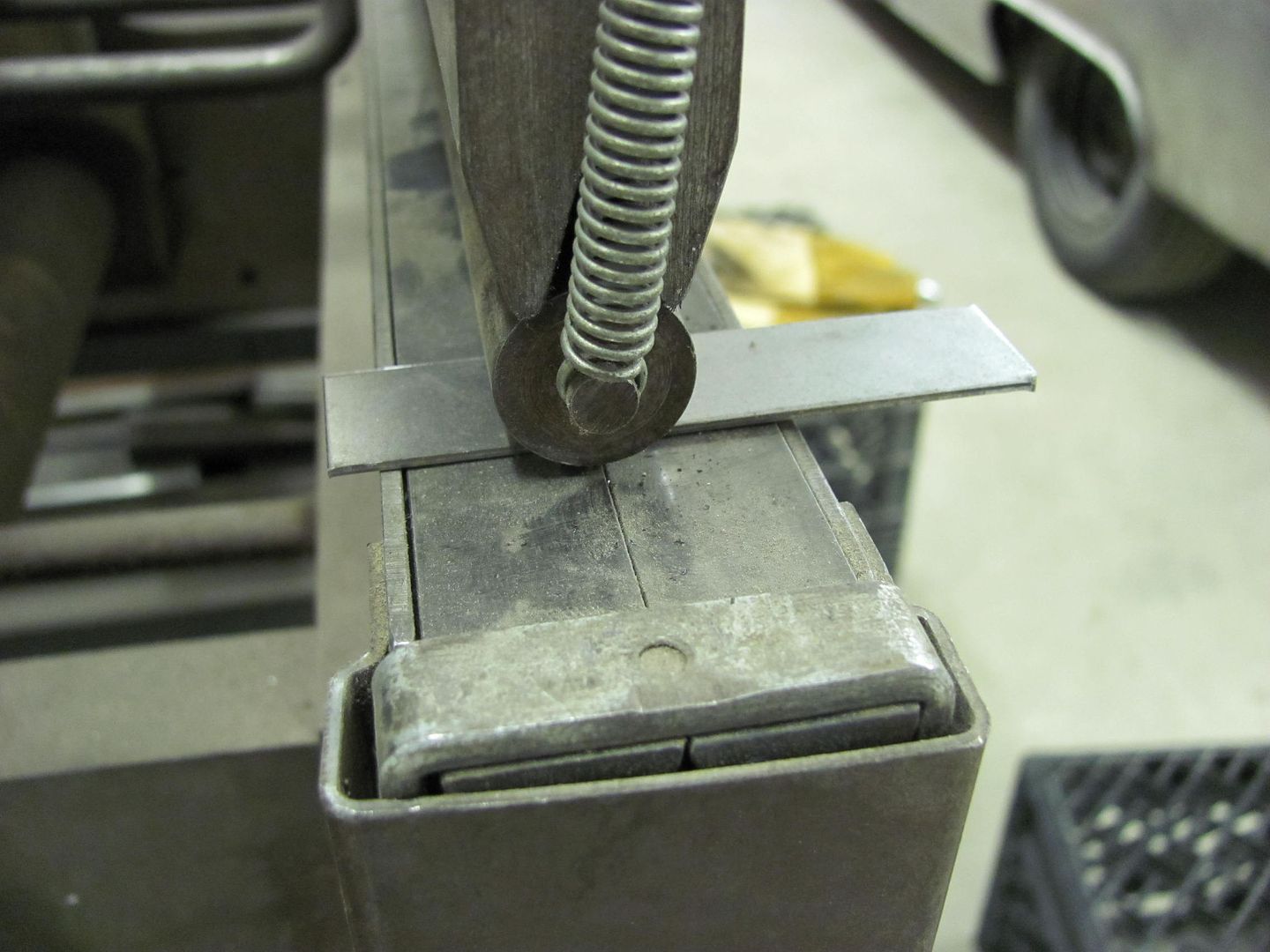

Time to finish this part up....

All cleaned up....

Comment