..

..

Announcement

Collapse

No announcement yet.

55 Wagon Progress

Collapse

X

Collapse

-

I like the round ones. Three should fill it up and hopefully not look too busy. The squares seem to fit better but they sort of clash with the round everything else about the car. If they were rounded rectangles, maybe the would work better for me.Last edited by Beagle; May 1, 2015, 06:34 AM.Flying south, with a flock of bird dogs.

Comment

-

The two round vents with a smaller clock in the center is a nice touch, followed with round vents on both ends – the clock would be a classy surprise and silently illustrates the thought you have put into your project.

Love your work, and thank you very much for documenting and explaining your process. These threads have encouraged me to try some metal work I would have never attempted before being enlightened by your work. A “Redneck Press” with the tubing flare kit solution is just one example of how you help us understand the way a thinking man get’s it done, Thank You.

Hardy Handshakes, SwedeDragWeek 07, 08, 09, 11, 12 & 2013 with 2nd place in DD

Comment

-

Went to a metal shaping workshop this past weekend, and just in case we needed a project to tackle, I took along one of the round vents so I could make some "buckets" as an option for mounting them in the lower outside corners of the dash. To prevent scratching, I covered the chrome with painters tape. As it turned out, we had plenty of other projects going on, and I never got to the vents. Removing the tape when we got home resulted in this:

So be forewarned, don't use tape to protect the chrome on the plastic vents from Vintage Air.

Also made a Xerox copy of the vents to be able to lay them out and test a pattern before cutting any holes.

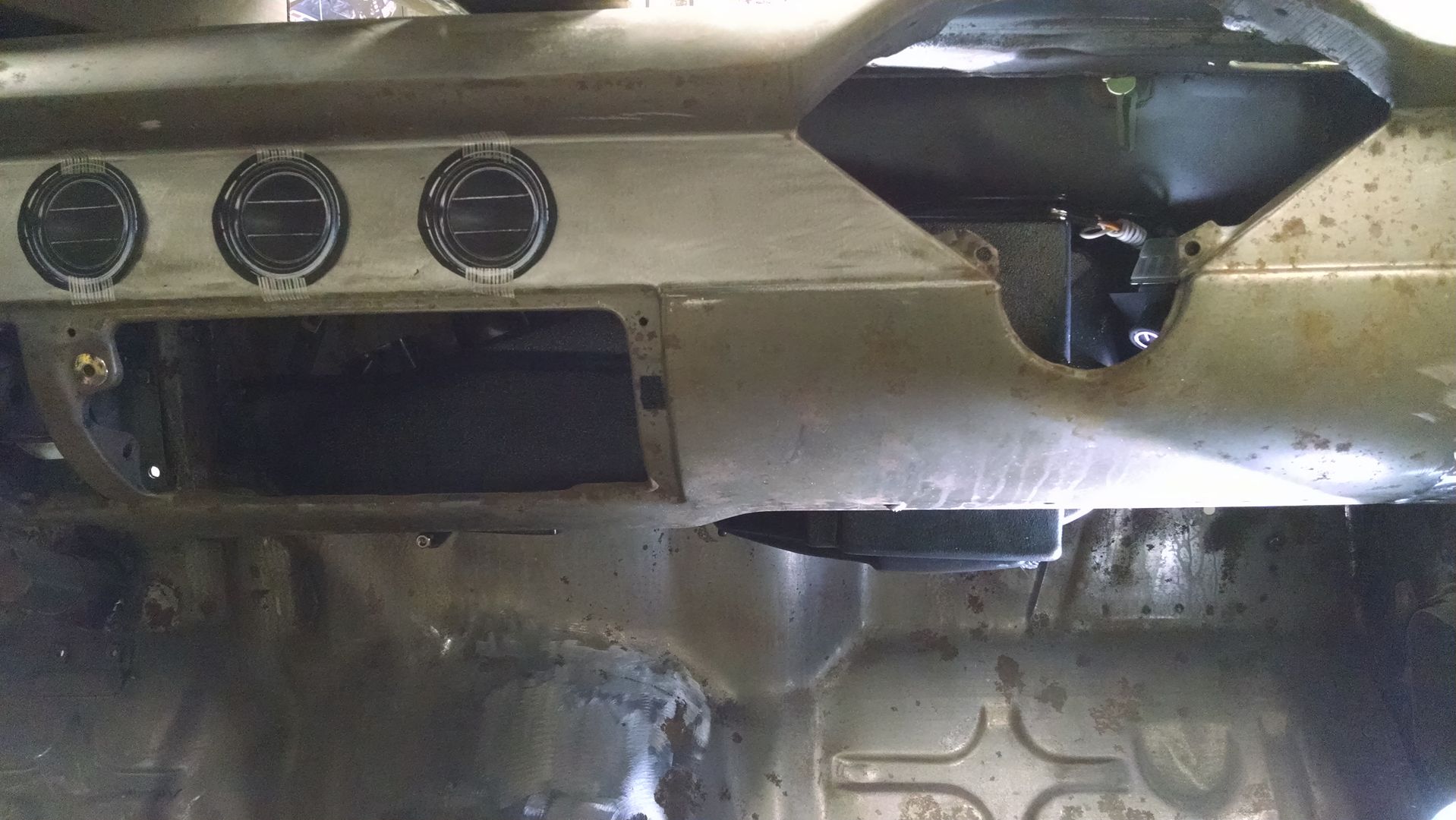

Thanks to all for the input on vent selection. Here is the 5 round pattern that the owner has decided on...

Comment

-

THANKS a gob! You've ruined me.

So I'm in line at the start of the Ohio Mile. Ahead of me (so I'm looking at his rear) is a really pretty cream/orange '55 Chevy 2 door coupe. So what do I notice? His tail lights don't fit! Probably within factory specs but now I know that they can be made to fit like they were custom made for the mounts (oh wait - your mounts were custom made for the lights).

Rock On!

Dan

- Likes 1

Comment

-

Dan, you're developing an eye for details. Your next CL purchase will go real well, I can see now.

Well, the past couple of shop nights we've had some detours and some back up and punts. Where to start..

Started with a test fit of the power antenna the owner had bought, installed somewhat easily and even clears the door hinge when closed by 1/4". But this trim ring on top is just......obnoxious. Anyone use a power antenna that is a bit easier to hide?

Next, lets get the VA unit under the dash to see how much room we have to work with on a radio..

Doh! We had planned on a single DIN chassis, so it appears the radio will need to be 4" deep, or go back into the dash, or go in a console. She did buy a console with the bucket seats, they all came out of a late model Monte Carlo. Let's give that a go.

Not much room for installing a single DIN chassis, but even worse the console tapers in at the bottom where the trans tunnel is spreading outward. So it looks like its teeter tottering. Doesn't match the car at all. So this looks like something else to add to the list, perhaps a custom made console is in order..

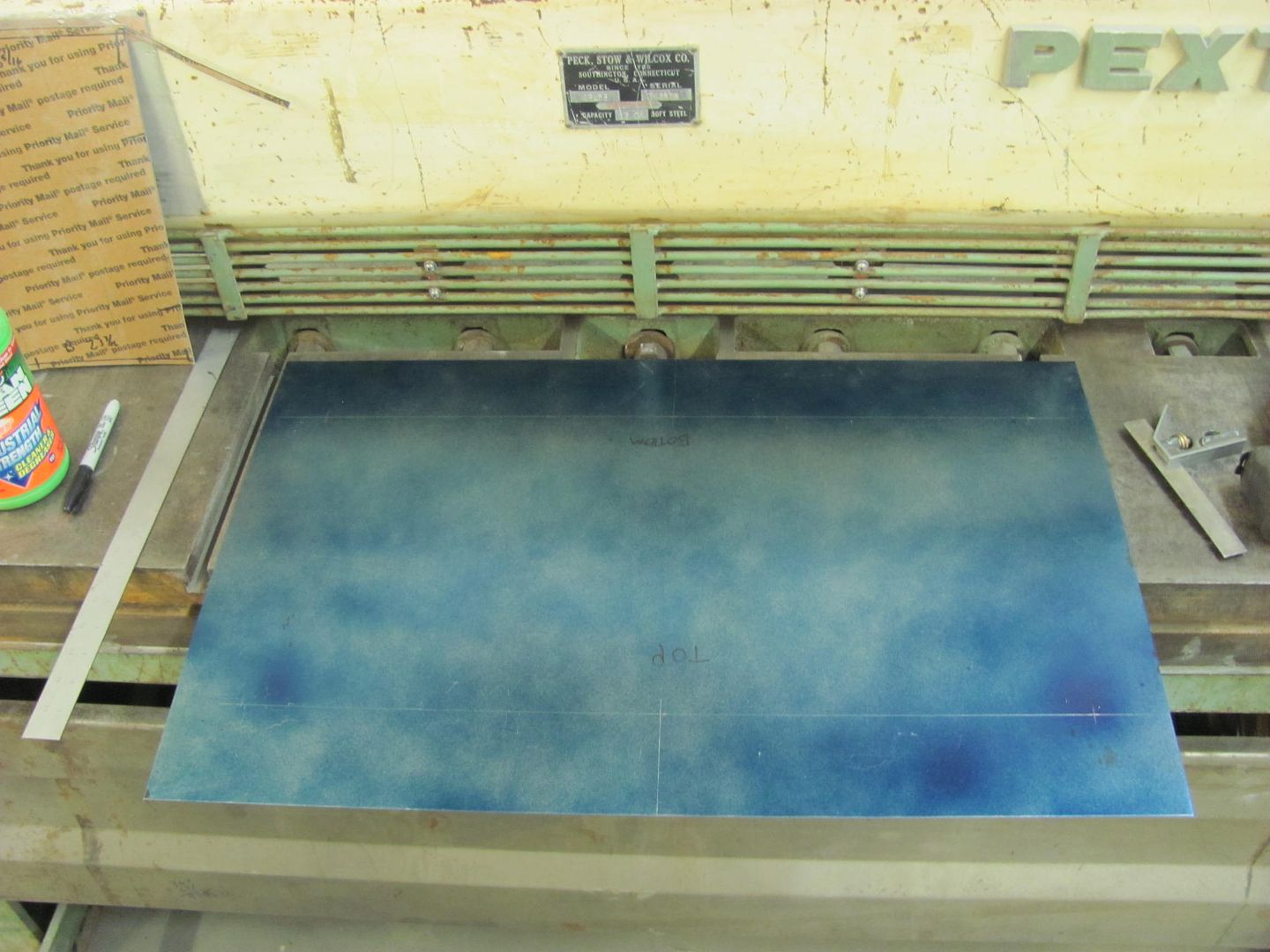

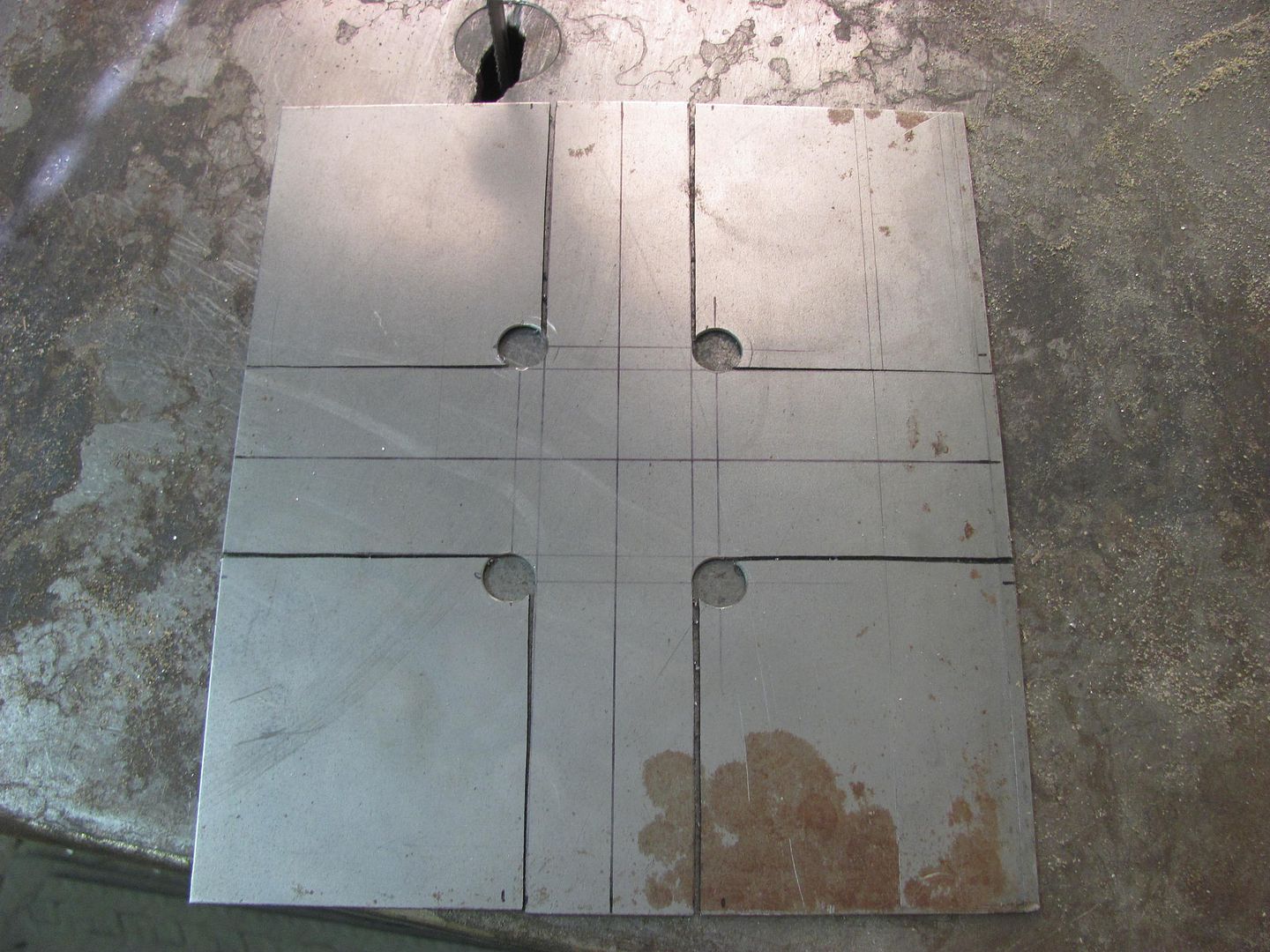

Since we're not doing too well inside the car, let's shift gears and move to the outside. We had a couple more parts to add to the pile awaiting powder coat. The side baffles of the core support had some hole alignment issues, must be off a 57 or something.... so we'll fill those in and get them re-drilled correctly. Next, we need mounting brackets for the radiator. These were made from some 16 gauge cold rolled steel..

We do now have much better clearance around the radiator petcock with the new improved version of the lower baffle..

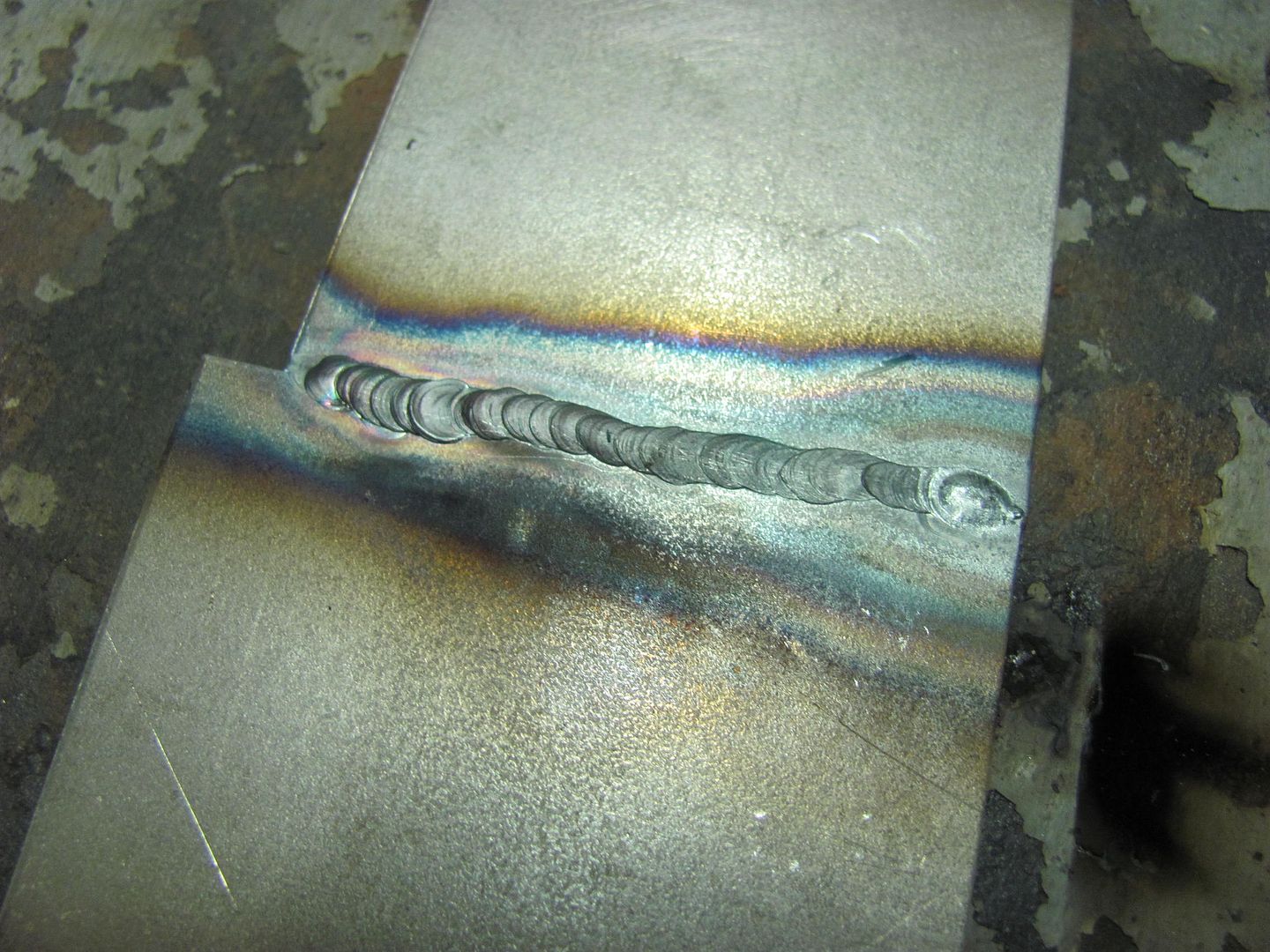

Kyle had learned some Tig welding this past weekend at GatorMeet, from Gator's boy Dakota. Dakota is quite accomplished for his youth, having won the state competition for welding. Here Kyle runs a couple of practice samples to get the machine dialed in... Seems he forgot his long sleeve welding shirt this evening.

I had shown him how to tack without using filler, and gave him more aspiration by showing him a no-filler fusion weld. All in due time..

Practice aside, here is the hole filling effort in the baffle panels...

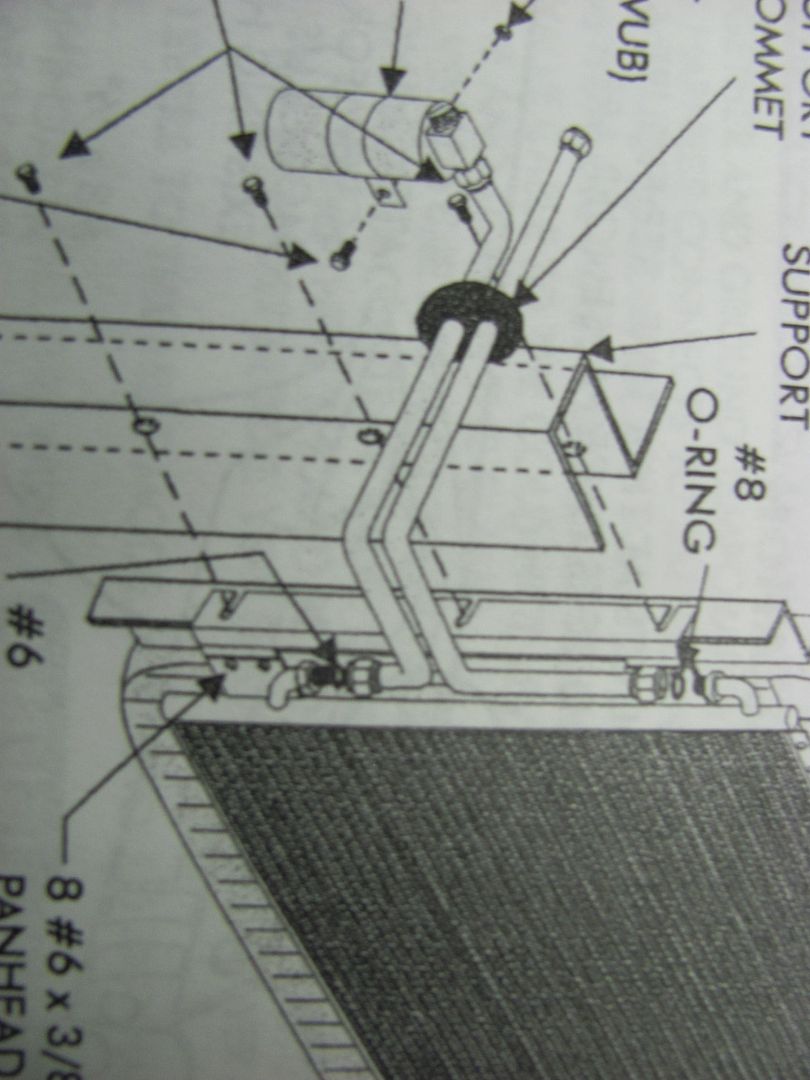

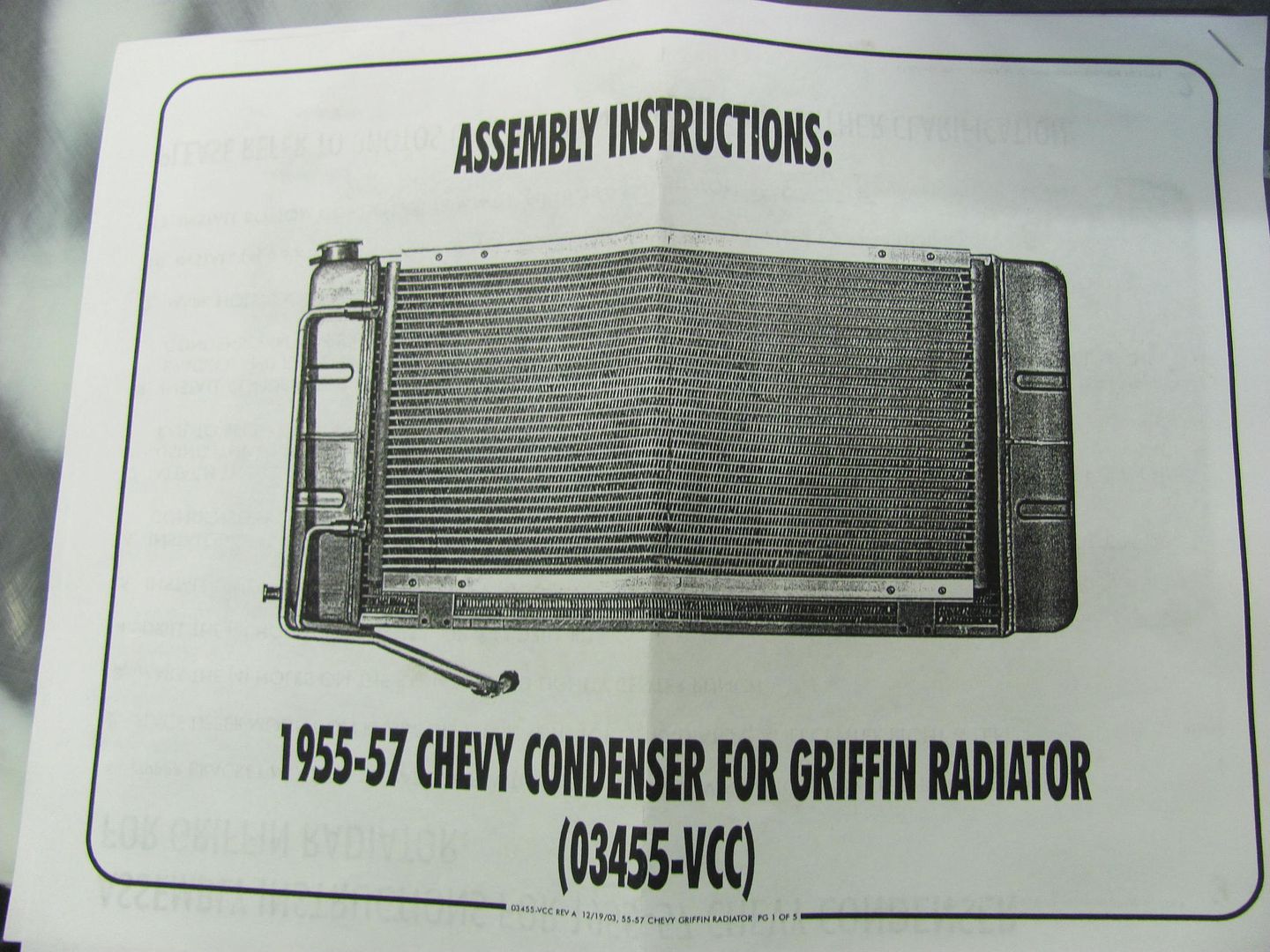

While Kyle worked on filling the holes, I had directed attention to the condenser and the holes we would need to add to the passenger side baffle prior to powder coat... just as shown in the book..

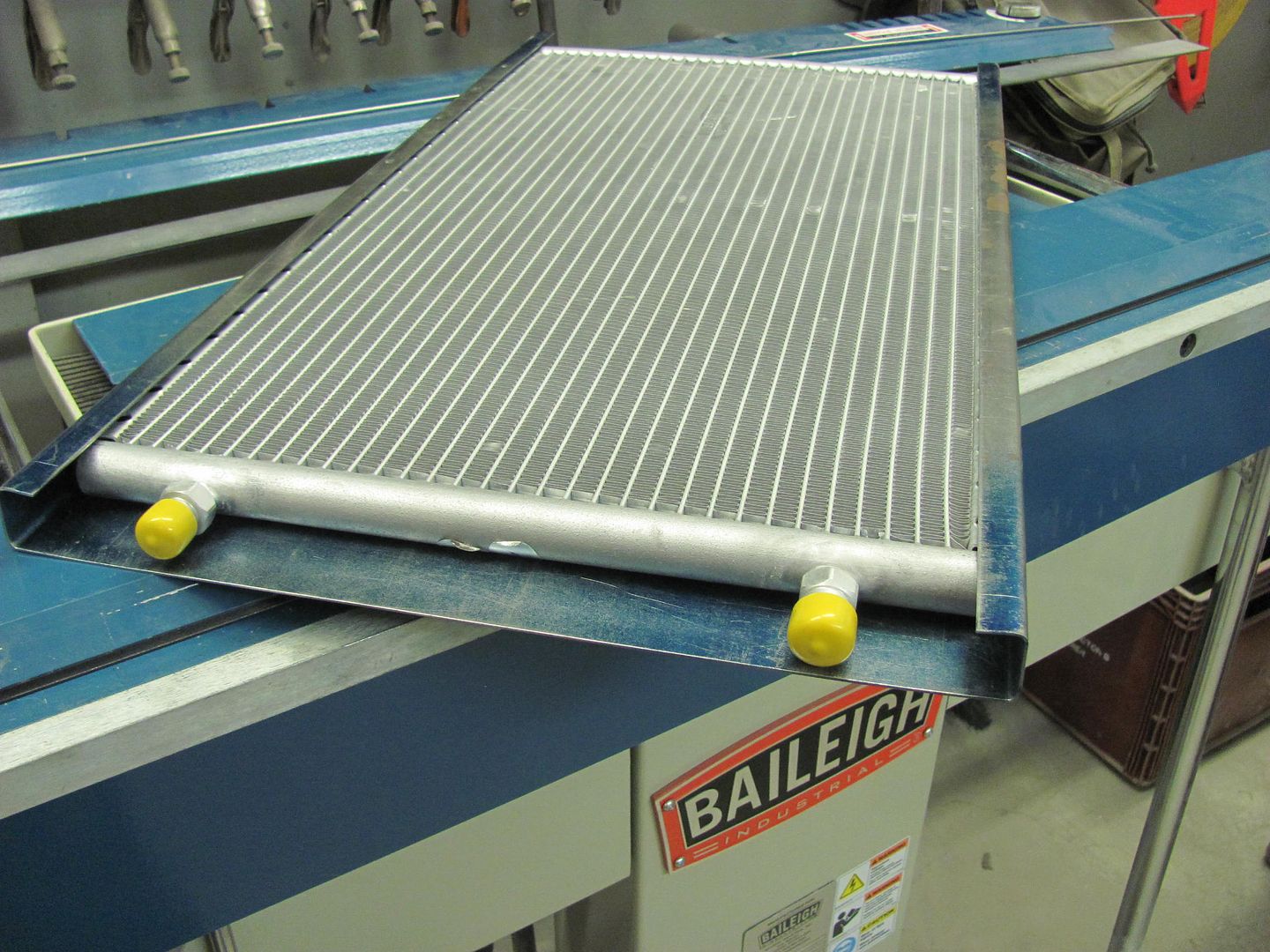

....only Murphy had other plans, it appears our condenser was intended for a cross flow radiator...

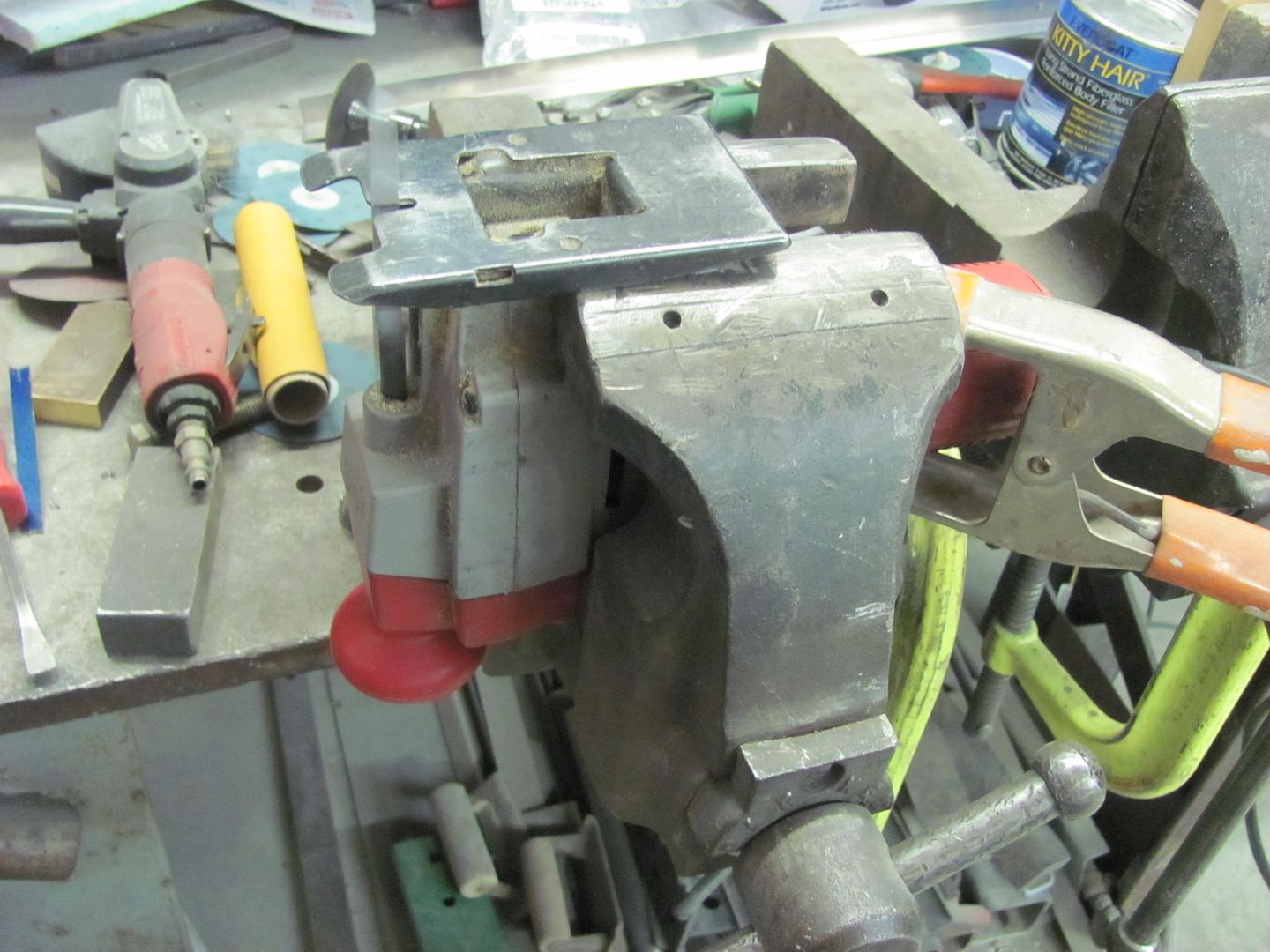

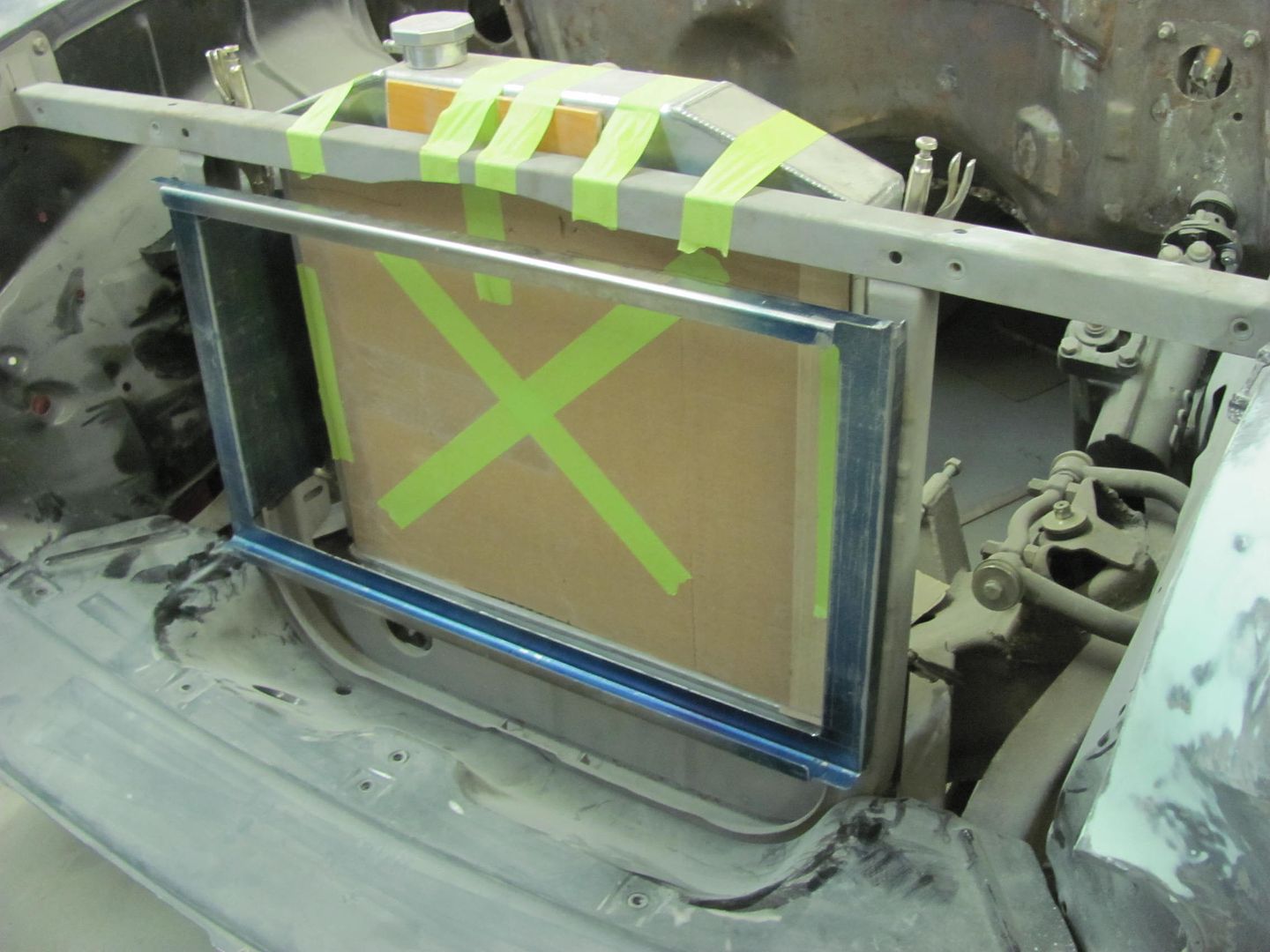

Hmm..... don't think this is going to work. So to back up and punt, the plan is to make a mounting bracket that will hold this universal condenser to a top flow radiator all while hiding those ugly holes that scream "I'm a universal fit". Then we'll have to get some new hard lines made up that fit correctly.

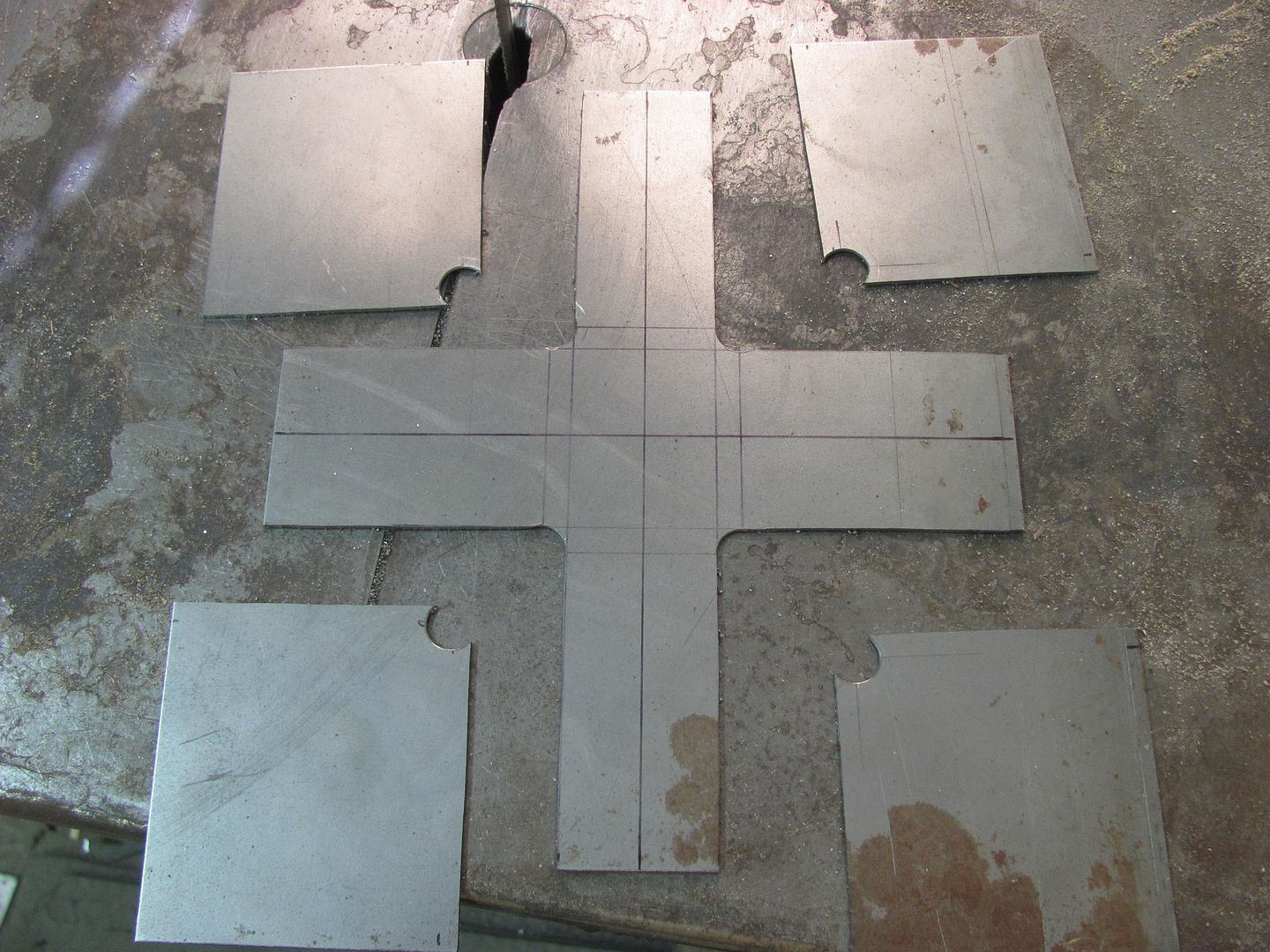

Layout of the mounting bracket...

Don't try this at home, it was done on a closed test track...

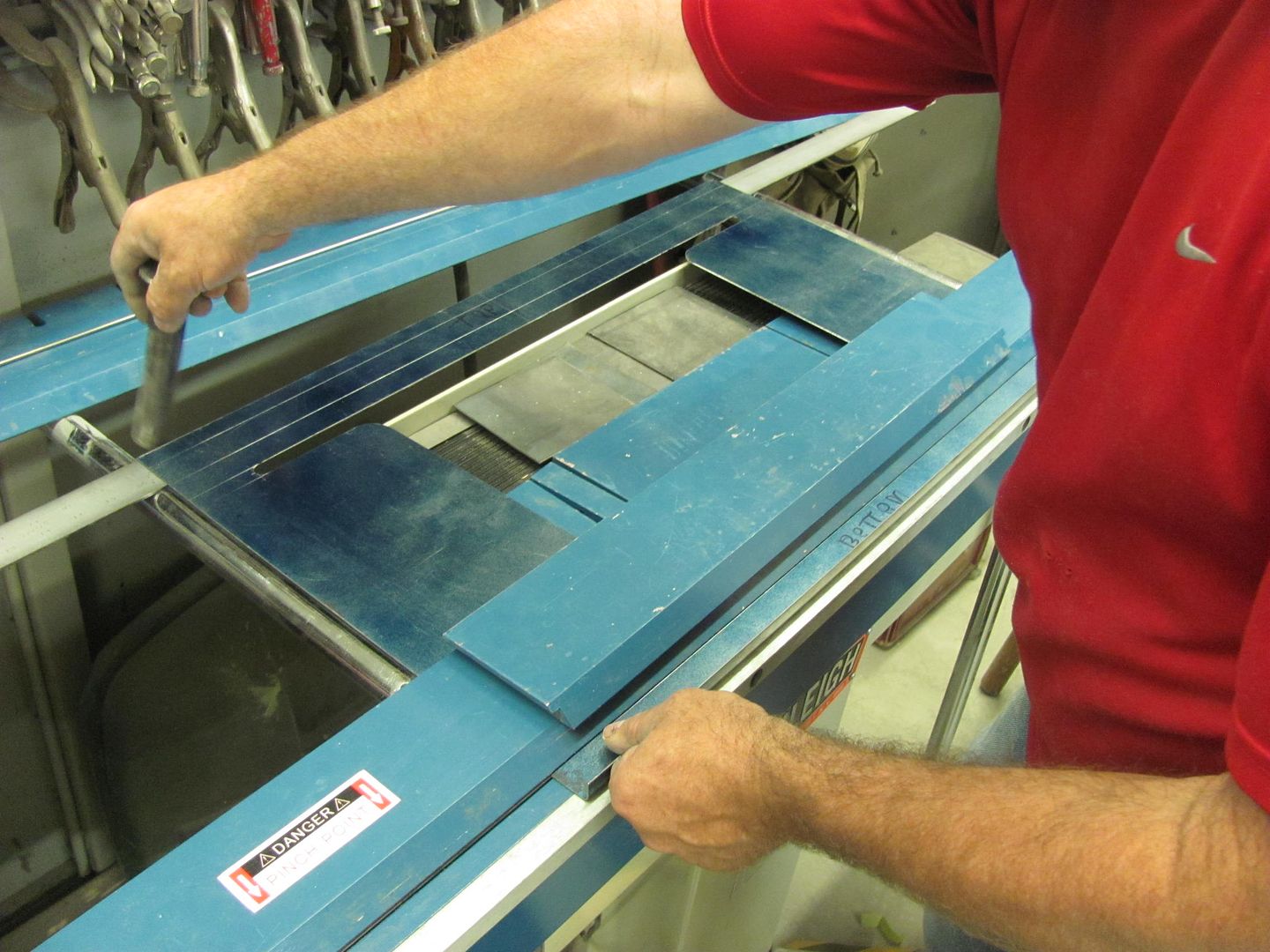

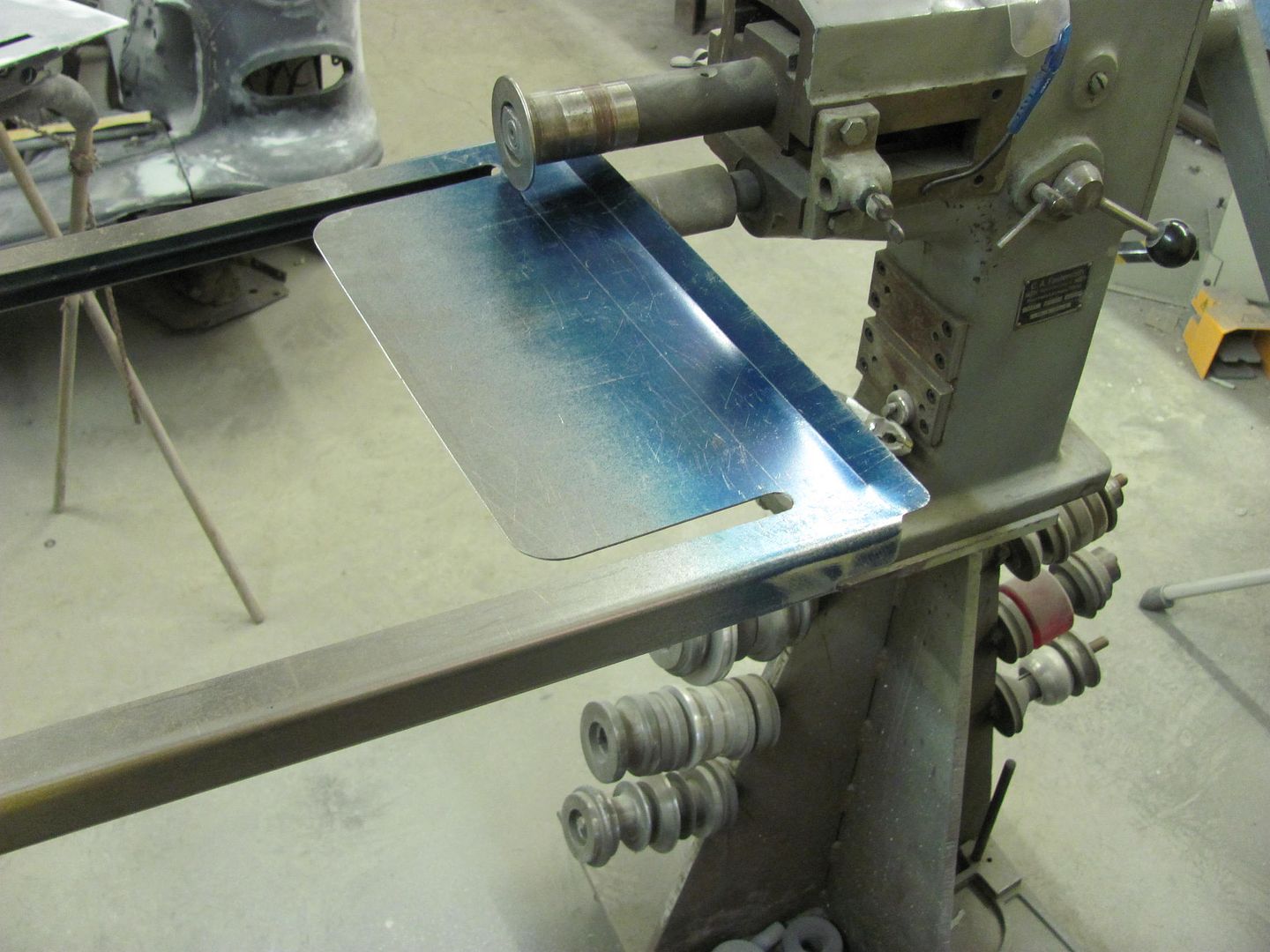

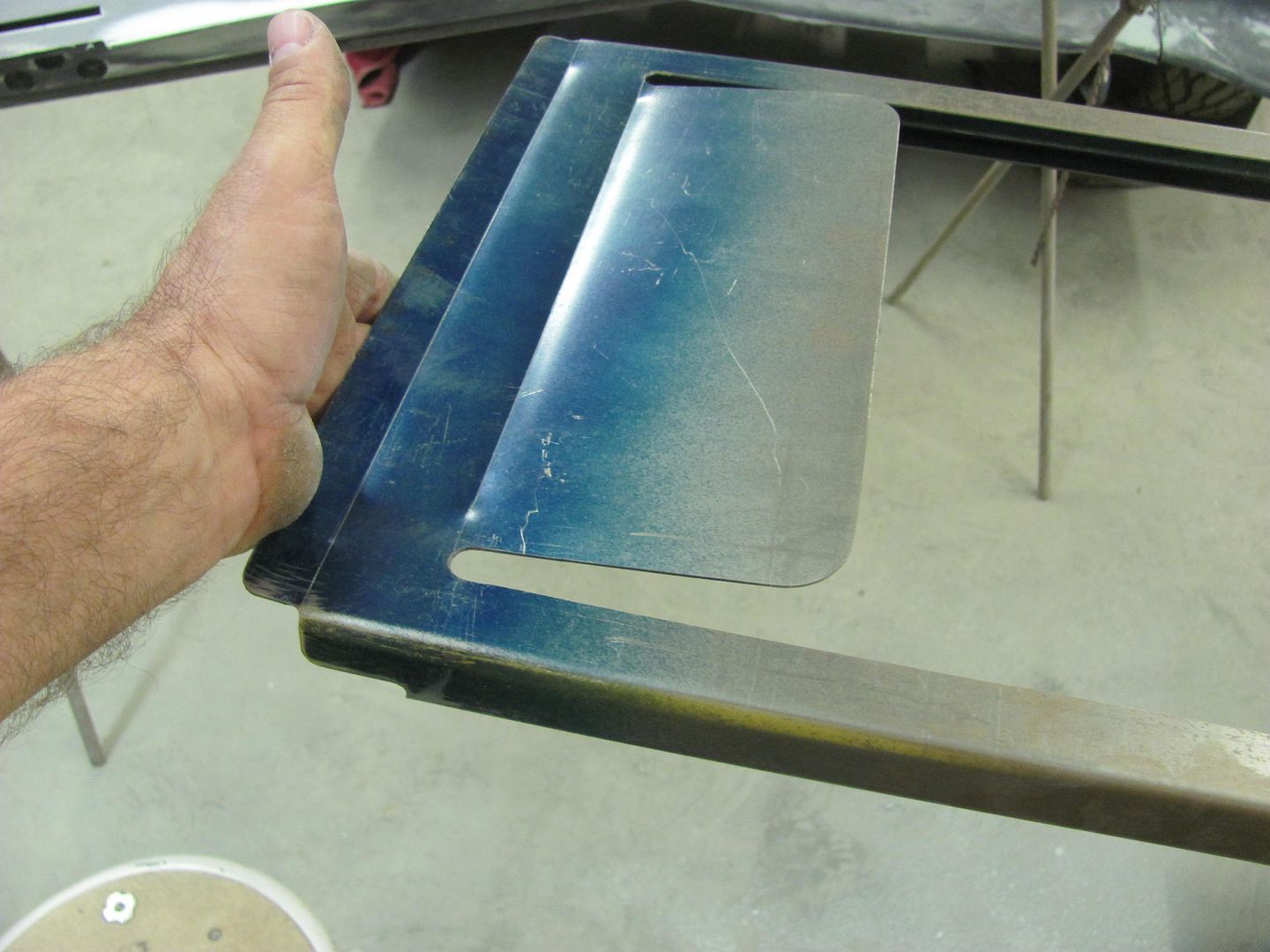

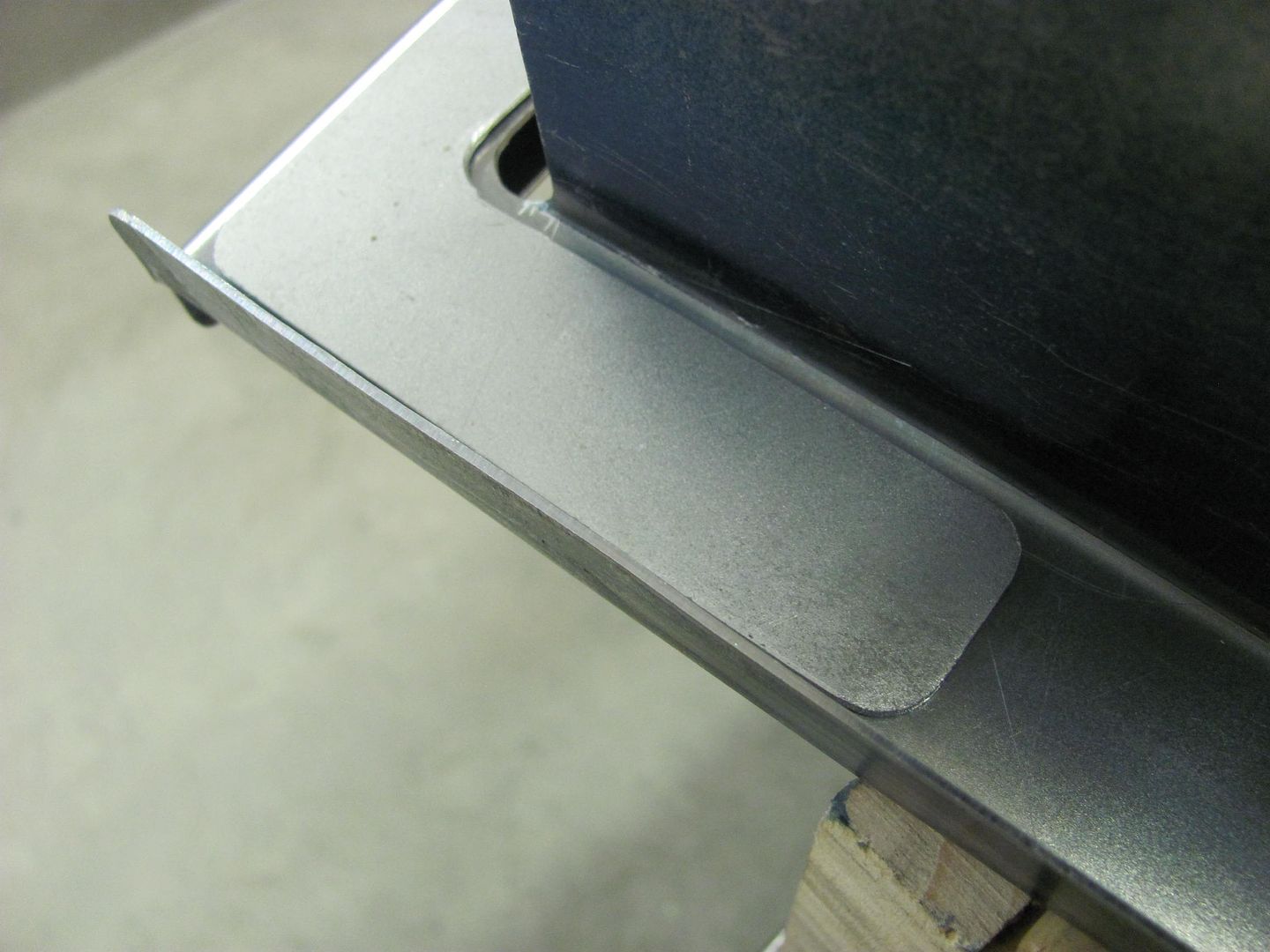

The ears inside will be folded inward to use the same bolts on the side of the radiator.. Here we are making the top and bottom folds in the magnetic brake, this design will help to hide all those holes..

....and we'll finish the mounting flanges next time..

Comment

-

Thanks for the response..

More progress on the condenser mount... The flange fold marks are run through the tipping wheel to better show the bend location. I've found that when using the press brakes this helps to "feel" when the upper die is located properly, less guesswork with the eyeballs where it's harder to see in the press brake dies..

Clamped in place for a test fit..

The side folds add some stiffening as well as hide the bolt heads for the core support baffle plates.

Test fit of the condenser...

Radiator brackets got a nut welded in the bottom hole, the condenser mount will get nuts welded in place for the top 2 sets of holes, so everything will bolt in from the outside in..

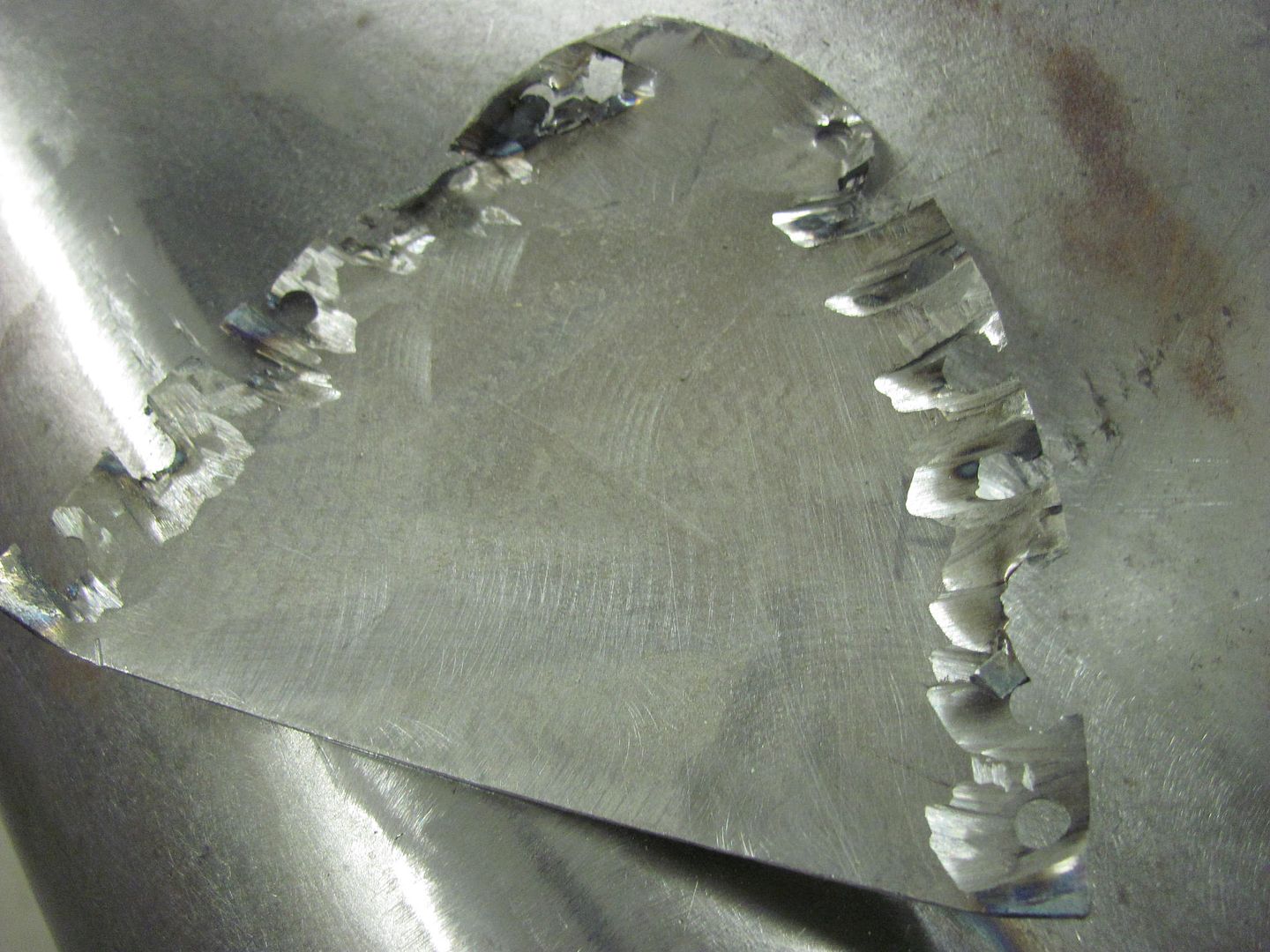

Making the slots for the radiator brackets, used a cone shaped burr....

Found that this cutter had less chatter when the cutting edge was perpendicular to the hole opening...

Comment

-

Some more details to iron out on the condenser mount, the corners seemed to "roll" a bit, so some corner braces are in order..

Using 16 gauge cold rolled, holes drilled to provide an inside radius to help prevent stress cracking..

Plug welds to hold things together..

Bob Heine over on GJ suggested using a Corvette antenna as they use an escutcheon with a flush fit, so I had a Corvette part delivery over the weekend, size of the business end is rather larger than the aftermarket one we had. As this fit in the void behind the A pillar (see in background between cowl vent and A pillar) and also needs to dodge the hinges closing, this did cause some interference. Dan thought this was from a late 80's/early 90's..

The biggest issue with the universal power antenna we have is that the top of the fender is considerably rounded, and the antenna escutcheon is designed for flat. So we are also looking at the factory piece, to see if we could adapt (drill hole larger) to use with the power antenna.

Comment

-

More progress on the condenser, used some machine screws to attach to the bracket, and some AVK style rivet-nuts in the frame of the condenser to act as a captive nut.

Bolted in place...

Meanwhile Kyle ties up some loose ends, finishing the weld across the remaining "shaved" lead seam on the passenger quarter.. It does need some grinding on the underside of the weld still but we'll wait for the car to be on the rotisserie for easier access.

Fitment of the Driver's side tail light... this was even worse than the passenger side in fitment, and we did need to make a relief cut at the top, but after some massaging, it's getting close. A few more tweaks to get this done and then the headache of installing the motorized tail light pivot for fuel fill access..

Comment

-

Sorry for the slight hiatus, been in UK and just got back this past weekend. Time to catch up on what we had done before I left and what Kyle did while I was gone to take up my slack..

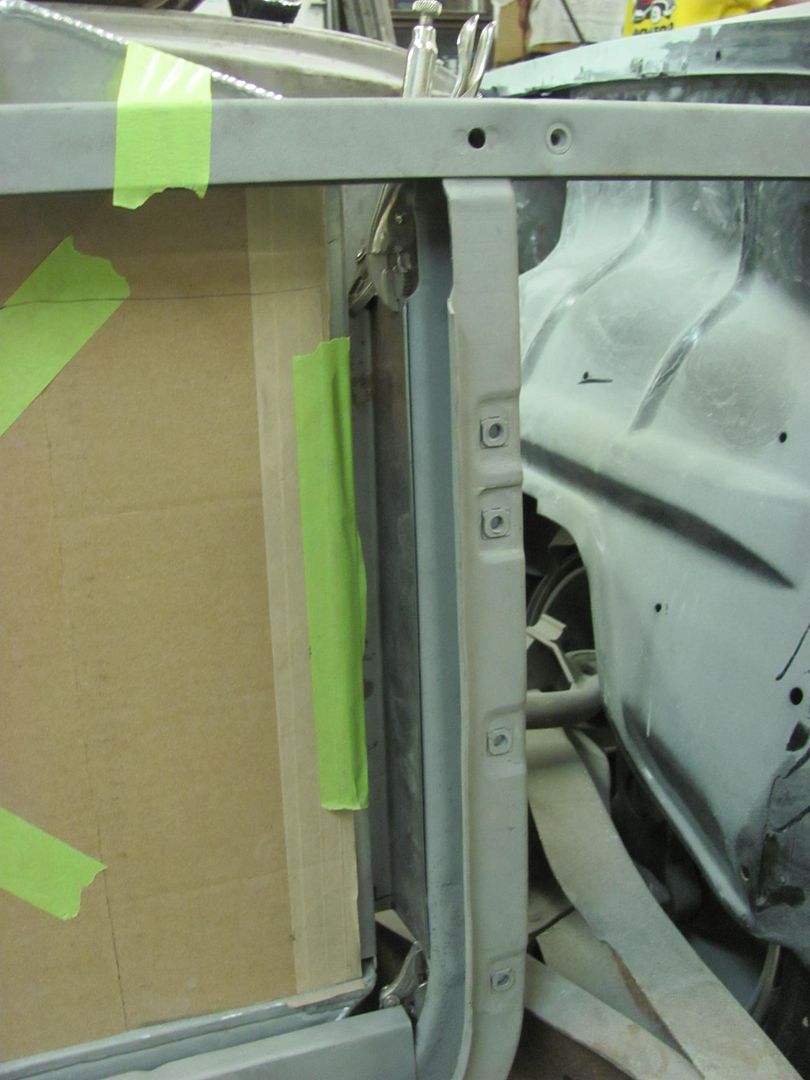

Part of our fitment issue with the passenger tail light was that we are installing the "hidden fuel fill" which required the removal of the brace welded in the opening. Next, when the old quarter was cut off and the new one installed, without the brace in place both pieces tended to wrap to the right, which can sort of be seen in the following picture, where its flush above the inside corner and rotates to the right upwards of that. The outer quarter was rotated in a similar fashion. We weren't having much luck in resolving the issue with the top weld seam remaining, so a relief cut was added, a restraint device employed to make use of some off dolly bumping to eliminate some of the right rotation. I didn't get a good picture of it, but you can see where the inner quarter comes in considerably upwards of the tail light right corner..

Anchor

Off-dolly bumping...

Then some shrinking was used to pull in the inner quarter, and a 16 ga plate used to hold things in place while the top seam was re-welded.

Kyle got the seam welded closed...

And temporary brace removed...

Much better, almost ready to tackle the "fuel door" pivot...

Comment

-

Got another care package in the mail... The new escutcheon for the antenna looks like it will work, the hole size matches the nut on the antenna and we'll just need to get rid of the flat spot/keyway in the hole. Only I don't think we'll be using this one. Between a recess under the chrome and visible scratches in it, this one's going back.

On to the next new pieces, hopefully these fit better, Reproduction headlight buckets..... wanted to test fit all the headlight and turn signal pieces before re-priming the fenders..

Decided to use some AVK rivet nuts over the u-clips..

Parts fitted..

- Likes 2

Comment

-

Man that car is looking awesome I'm having so much fun watching it come together I don't know if I want to see it finished to soon.Greg & Mendy Dayton, Ohio 2007LH 2008LH 2010LH 2011LH 2012 1st 2 stops 2013LH 2015 1st 2 stops2016LH 2017 first and last stops . 2018 LH ("It's better to be dead and cool than alive and uncool!! Harley Davidson!")

Comment

Comment