Some weekend progress... Fine tuning the rear bumper fitment.

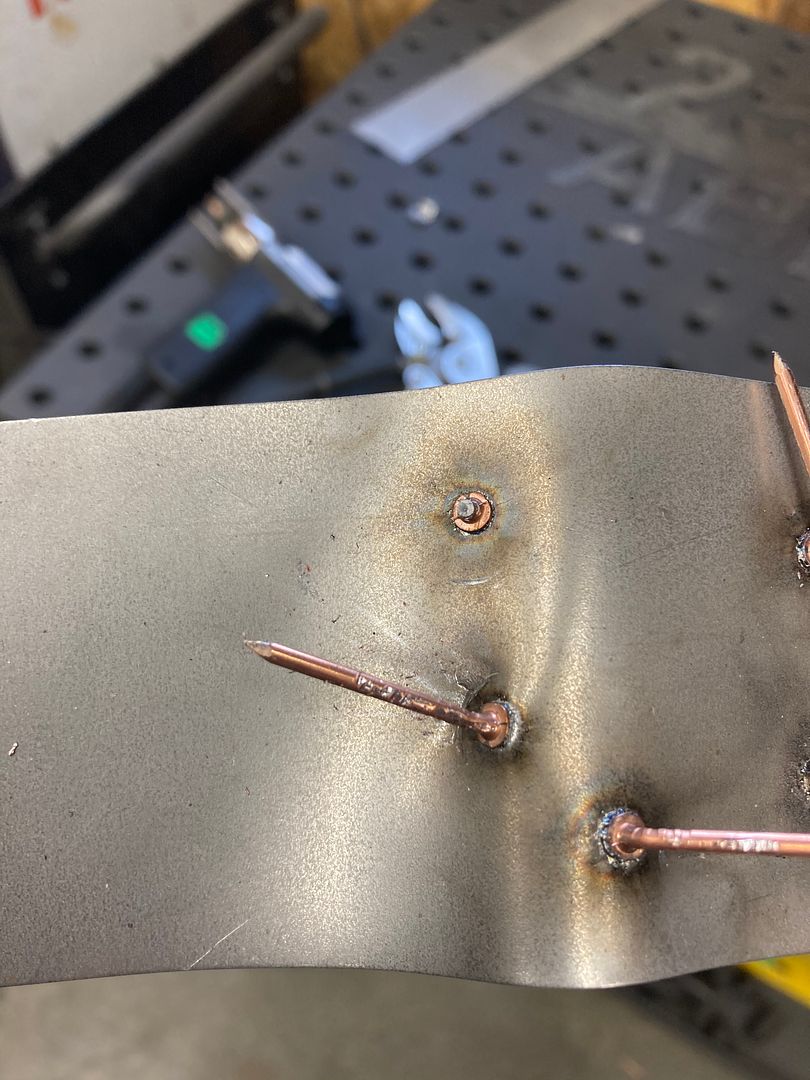

Driver's side fits well to the profile of the rear of the quarter...

Passenger side not so much, so the bumper is marked with some fineline tape for where we will sand down the edge to better match..

Leading edge of drivers side needs some trimming...

….as does the center section behind the tail pan..

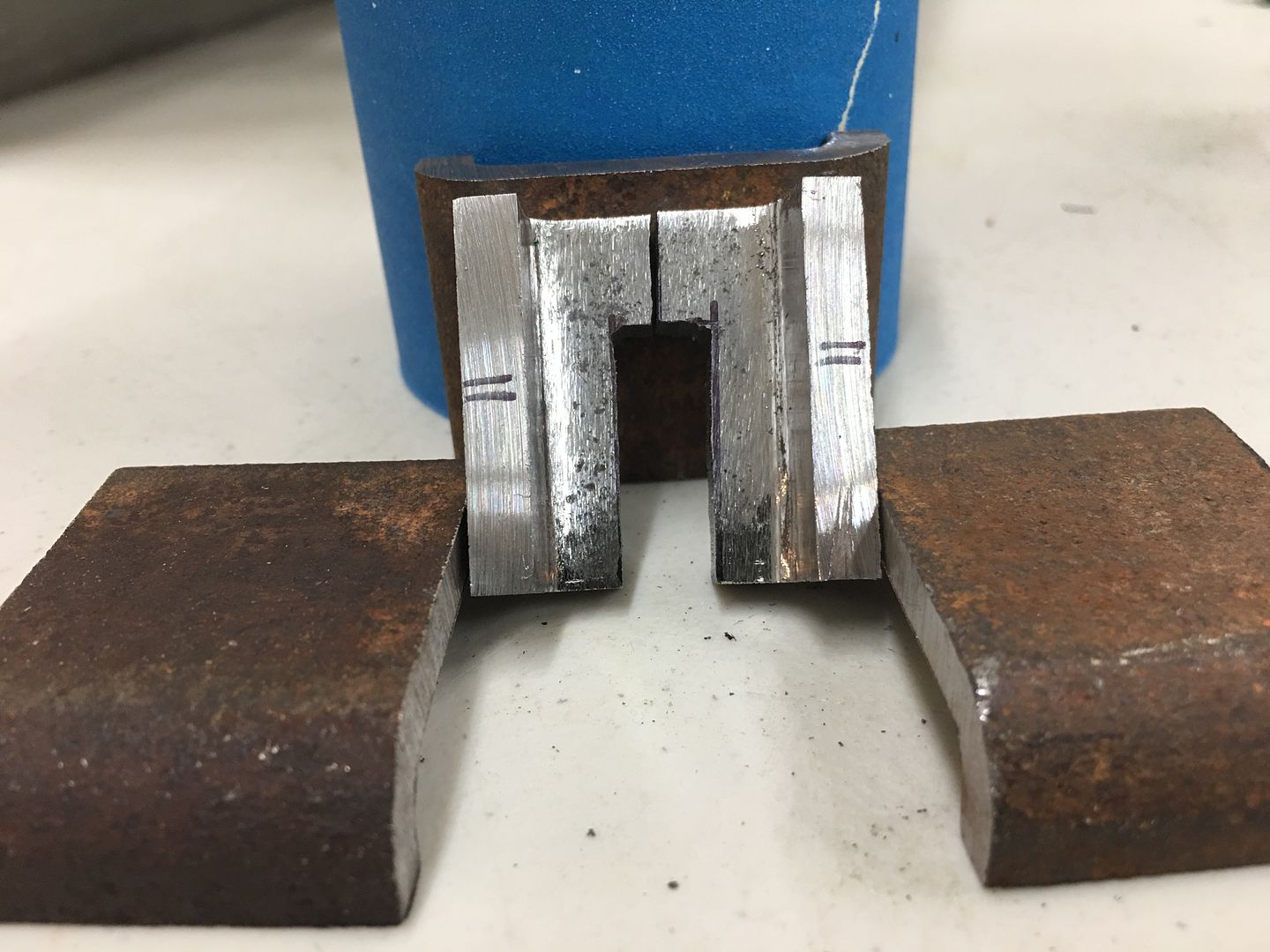

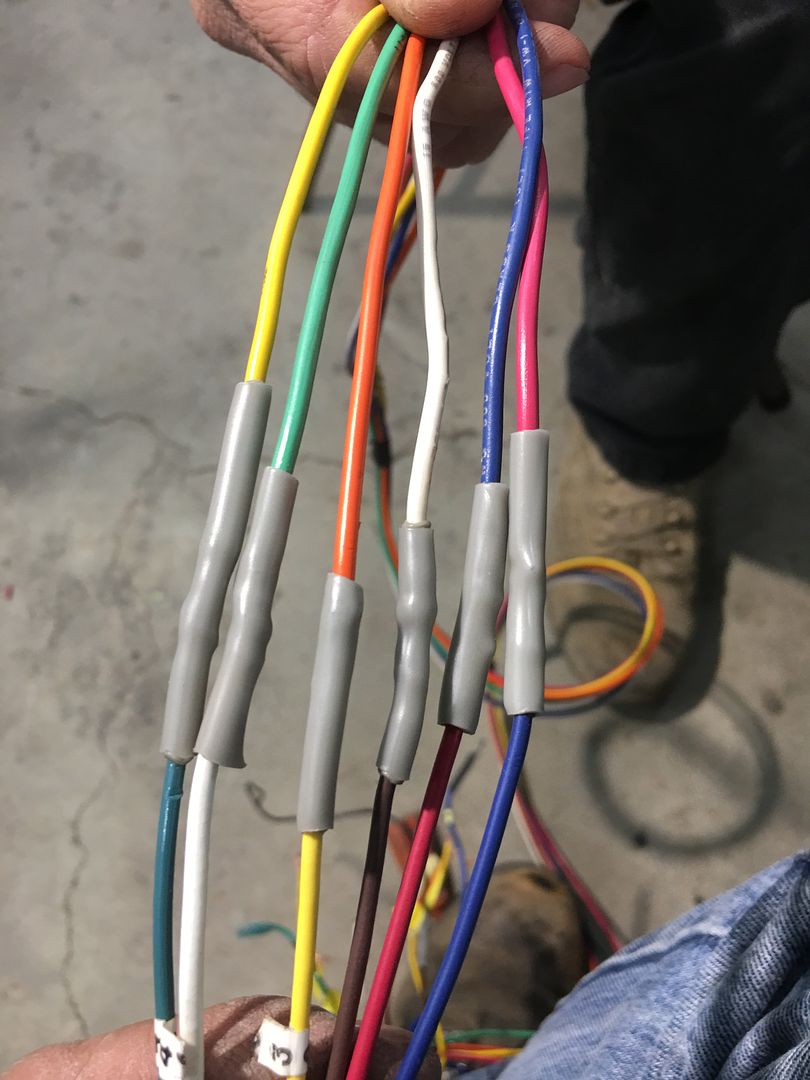

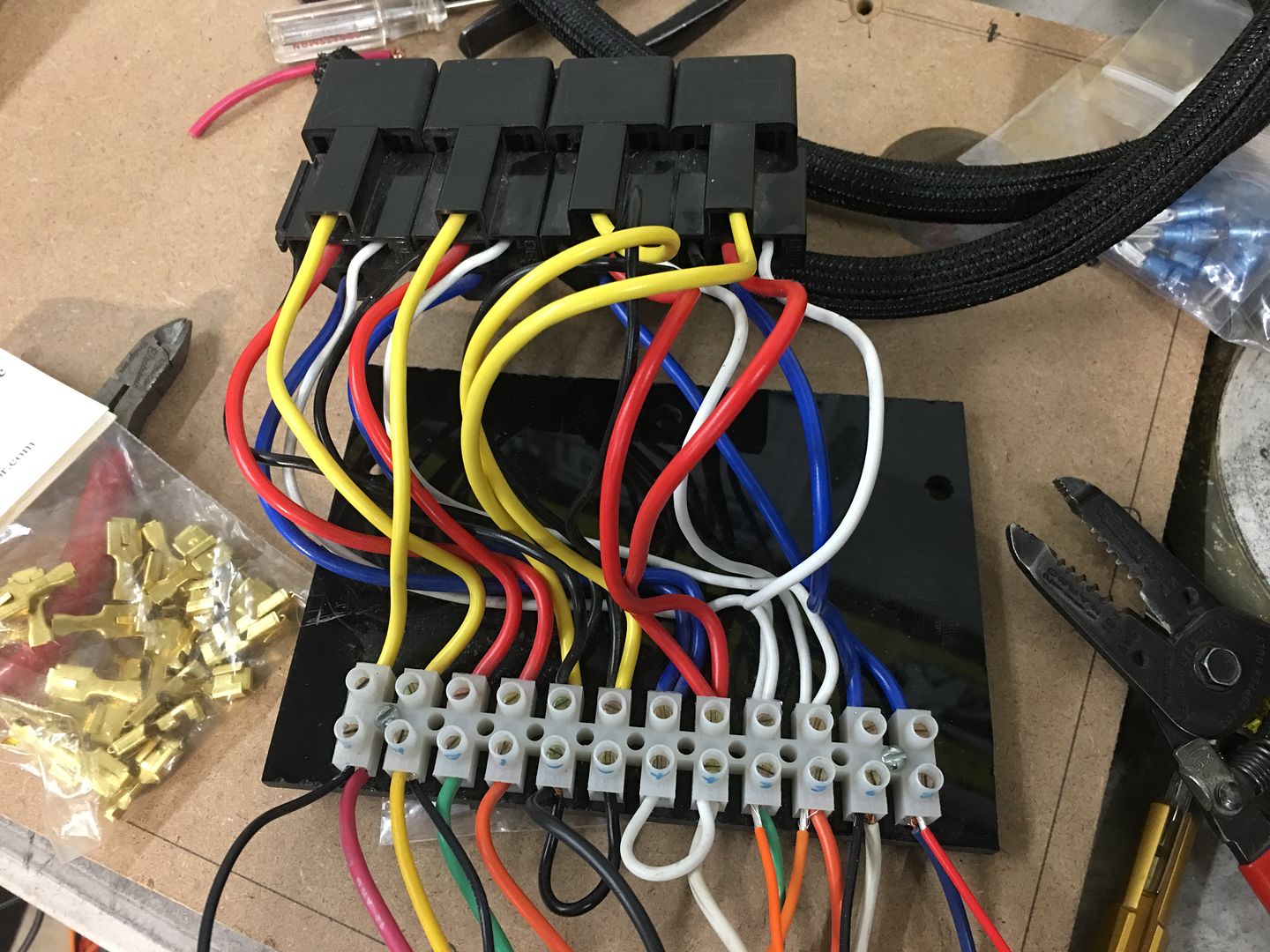

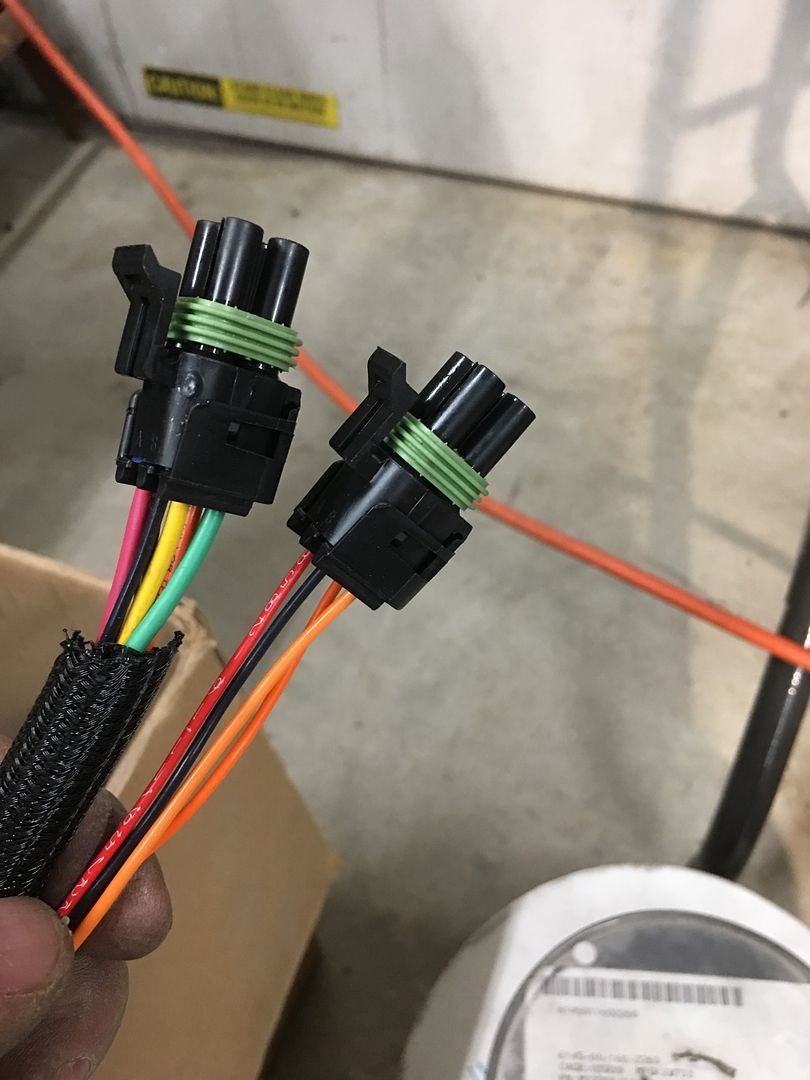

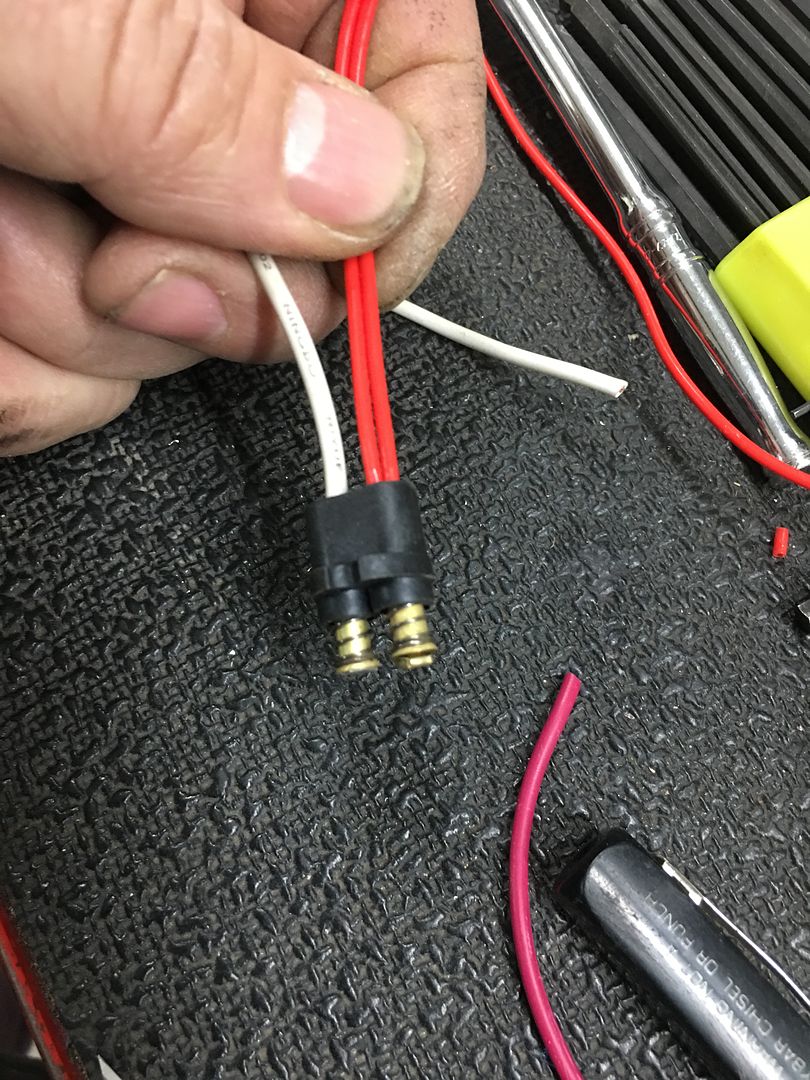

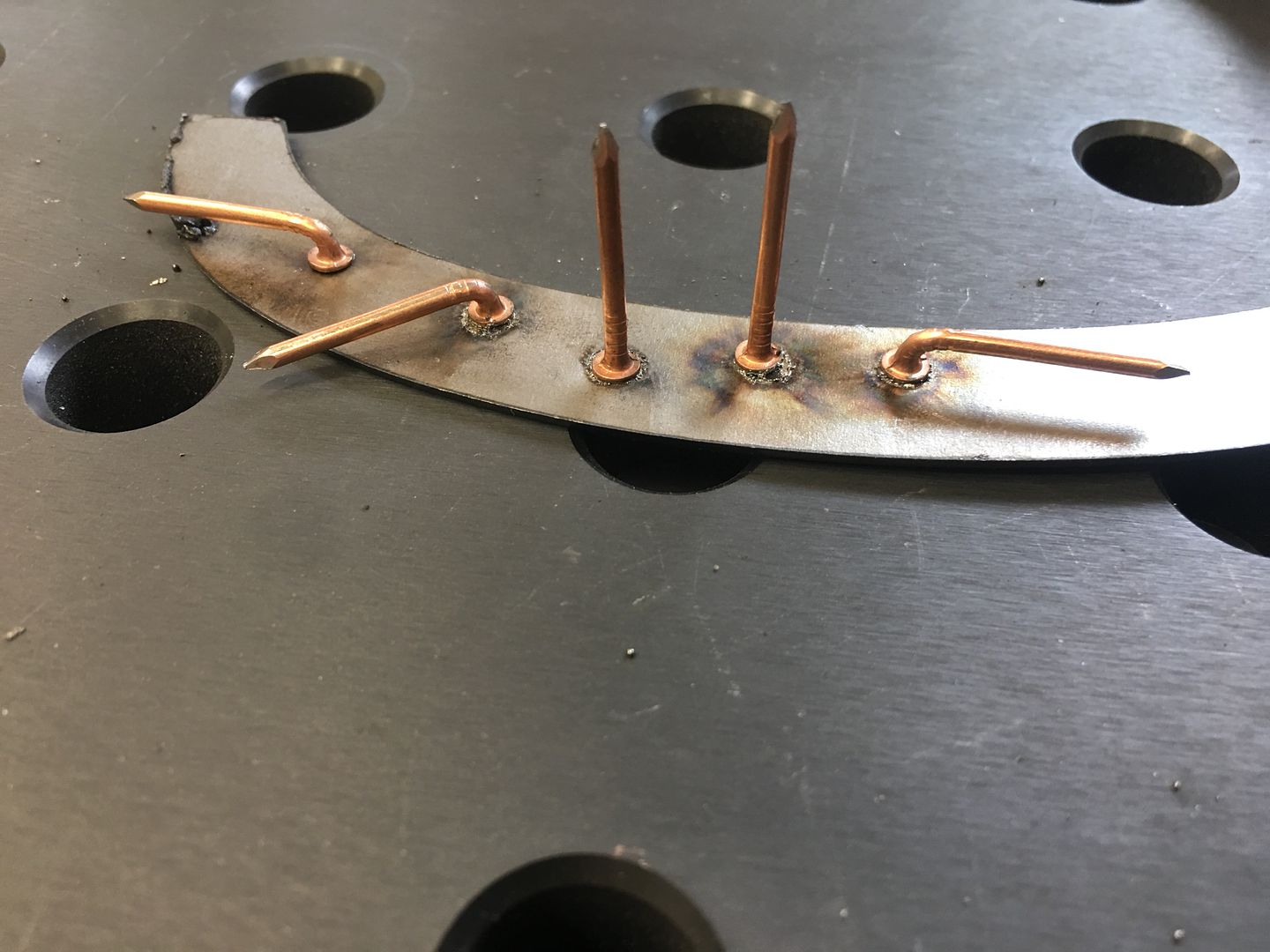

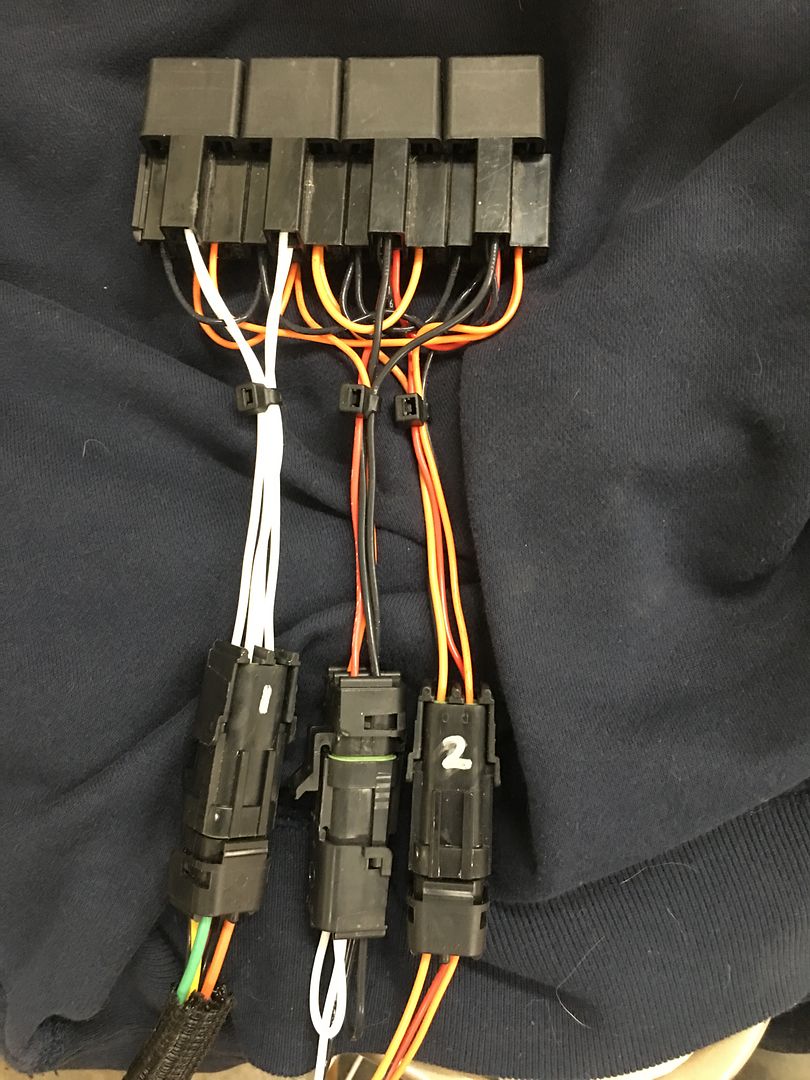

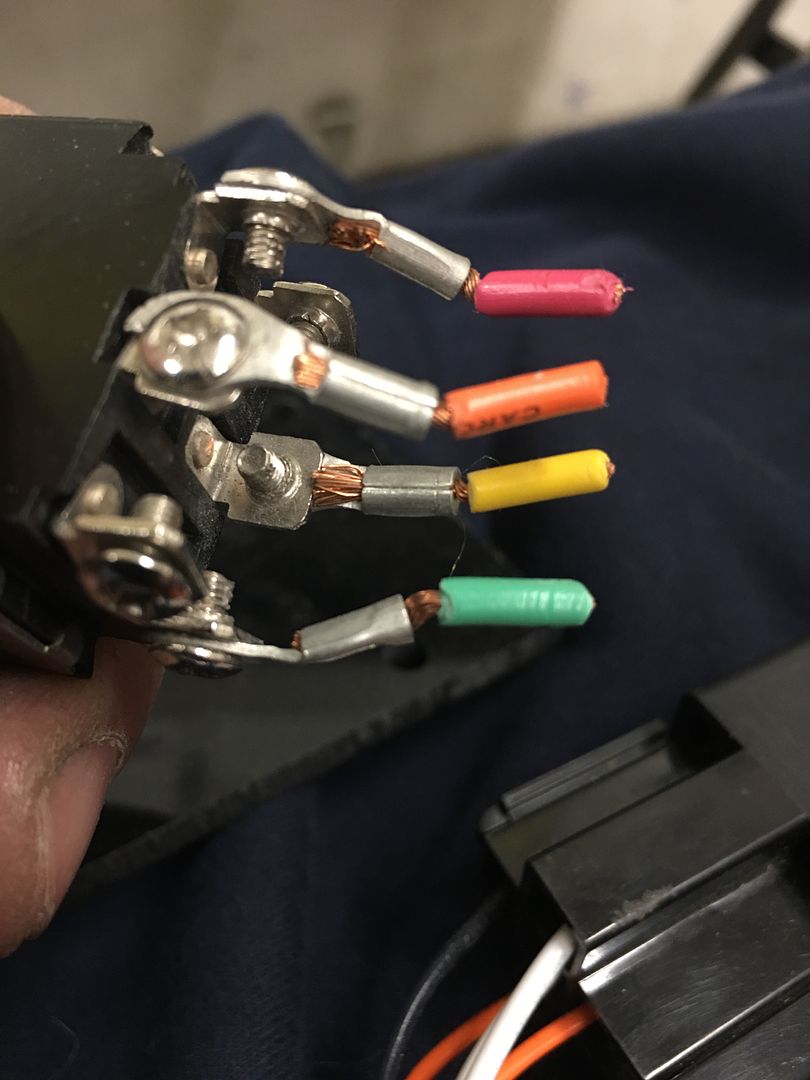

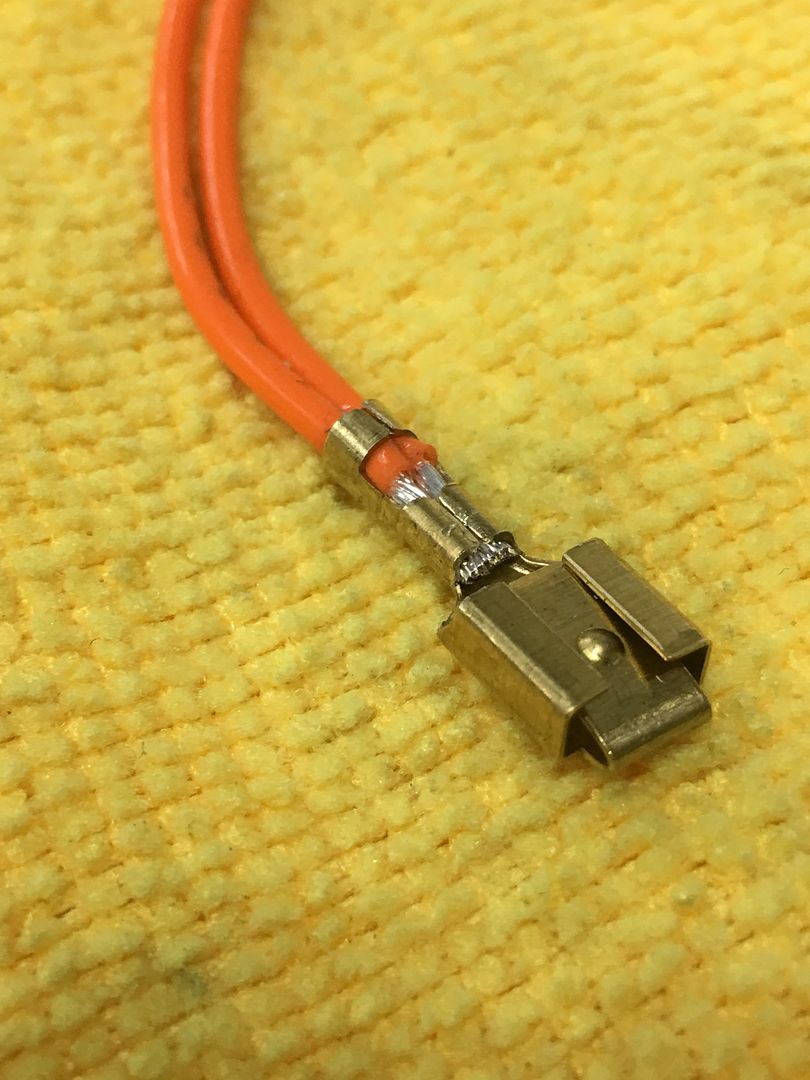

Next, in order to test fit the front bumper and provide the same "trim fitting" we will need to install the doors and front fenders. So our hinges got some new braid loom and a pull wire installed for the hidden wiring..

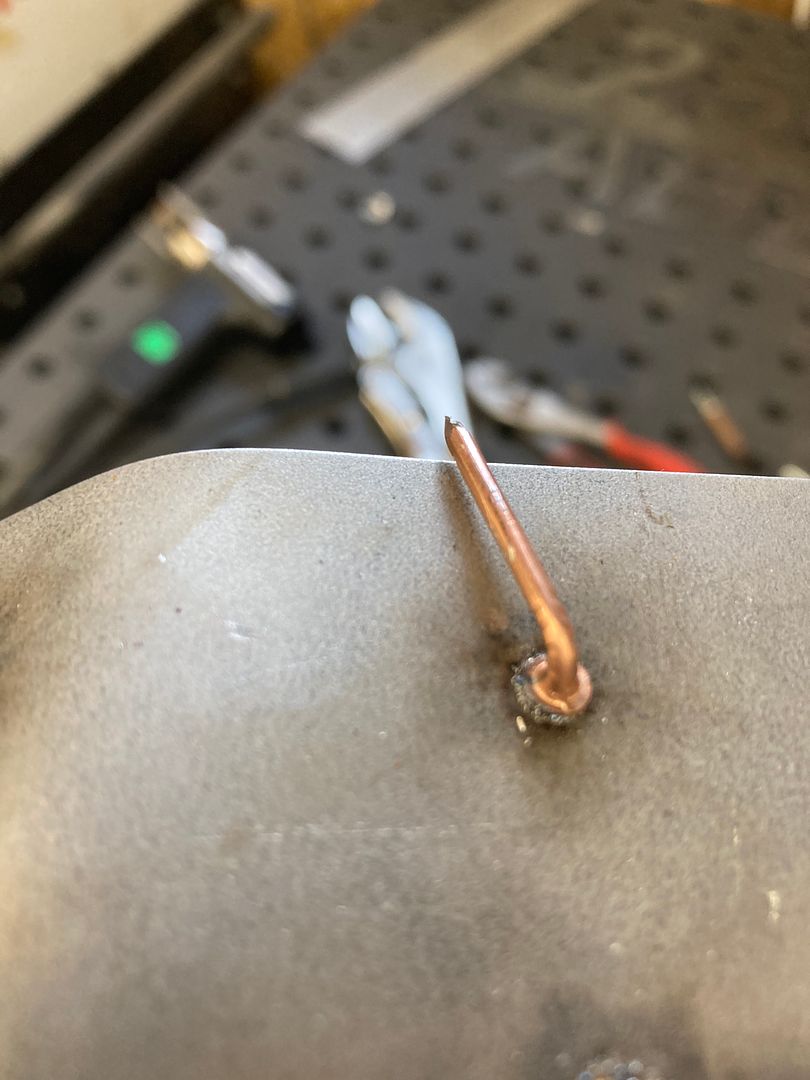

The tapped holes in the door's nut plates were chased to insure the fresh paint did not interfere with the bolts..

All buttoned up for the day, and under Kramer's watchful eye..

Driver's side fits well to the profile of the rear of the quarter...

Passenger side not so much, so the bumper is marked with some fineline tape for where we will sand down the edge to better match..

Leading edge of drivers side needs some trimming...

….as does the center section behind the tail pan..

Next, in order to test fit the front bumper and provide the same "trim fitting" we will need to install the doors and front fenders. So our hinges got some new braid loom and a pull wire installed for the hidden wiring..

The tapped holes in the door's nut plates were chased to insure the fresh paint did not interfere with the bolts..

All buttoned up for the day, and under Kramer's watchful eye..

Comment