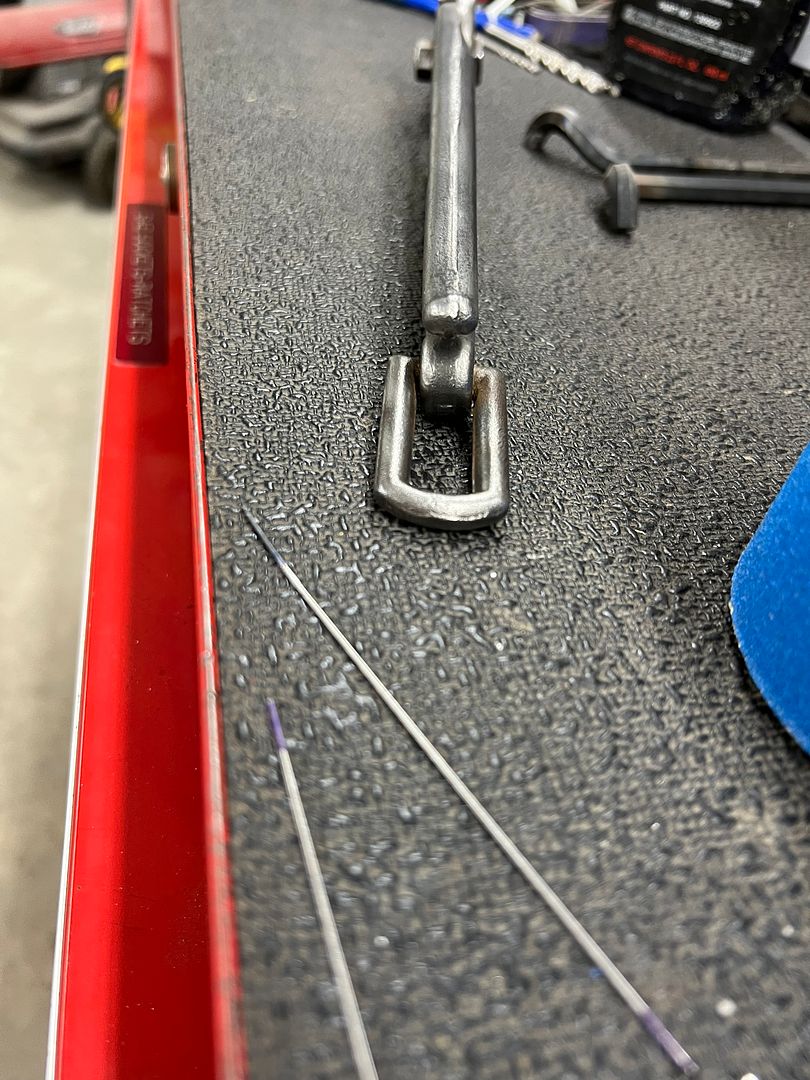

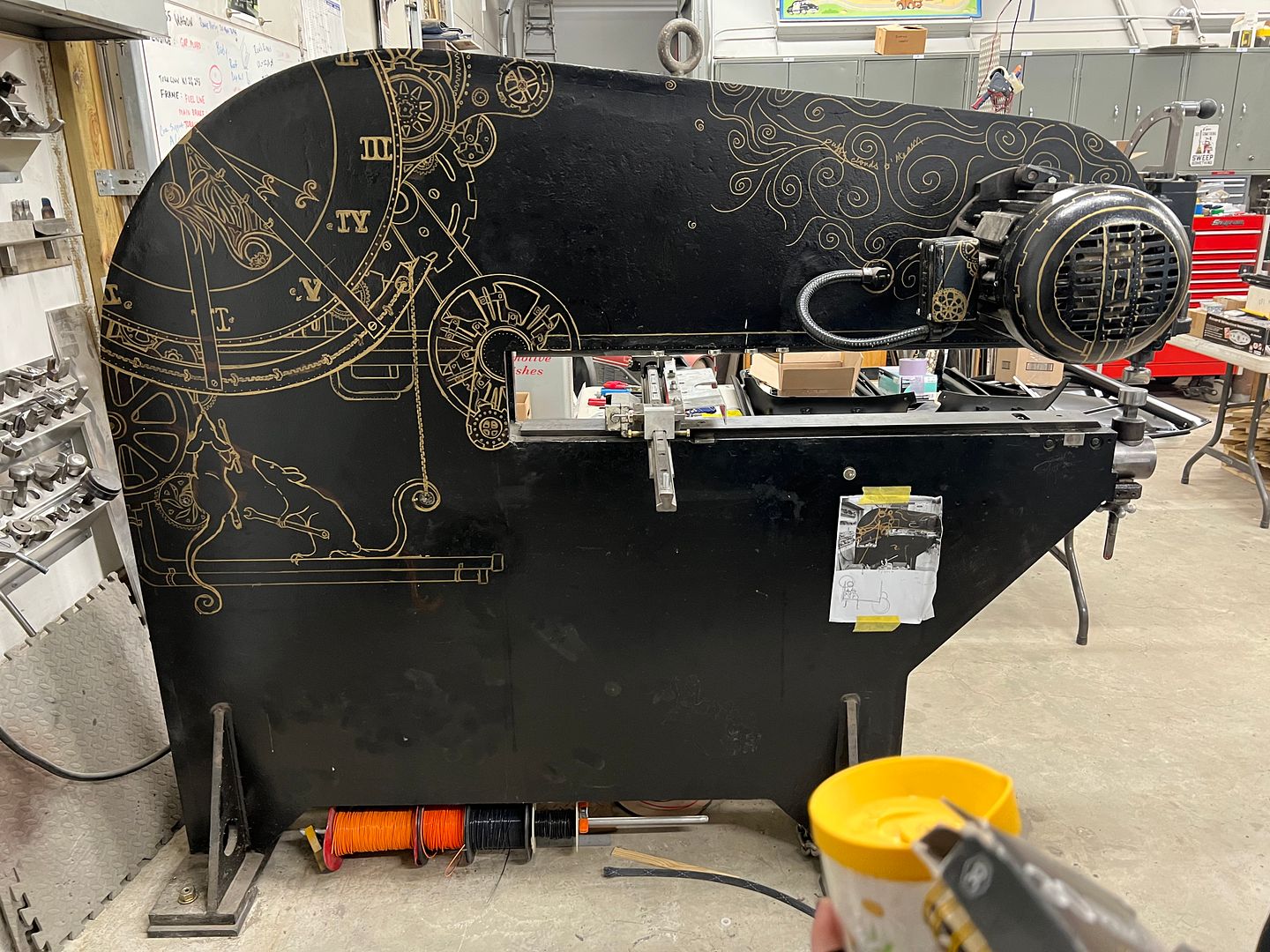

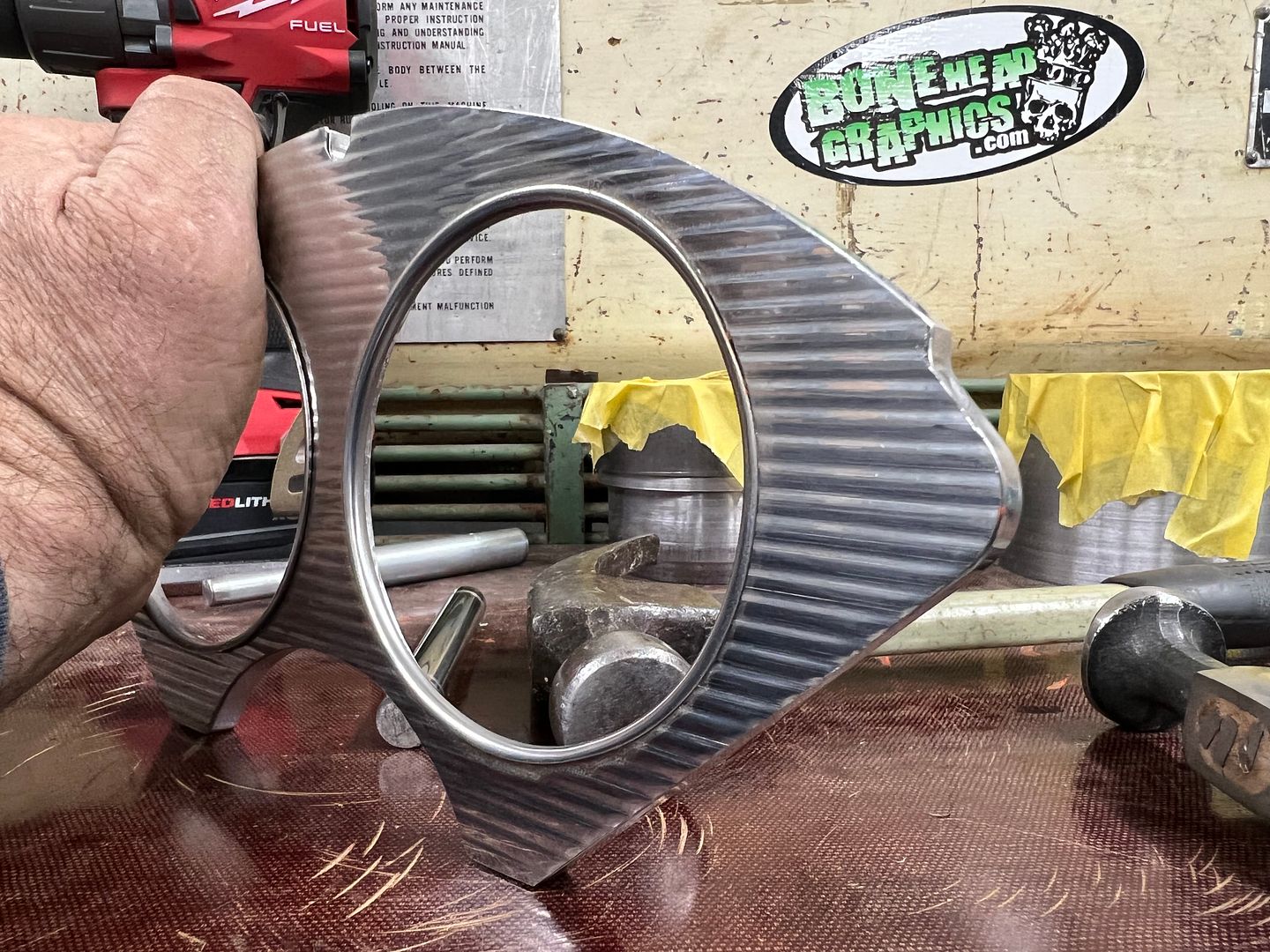

Then we changed out the thumbnail shrinking dies for linear stretch dies in the Lennox TE250 in order to tip the flange back horizontal again. We have a backstop / fence that had been notched for tooling and this did a nice job of getting the flange depth consistent.

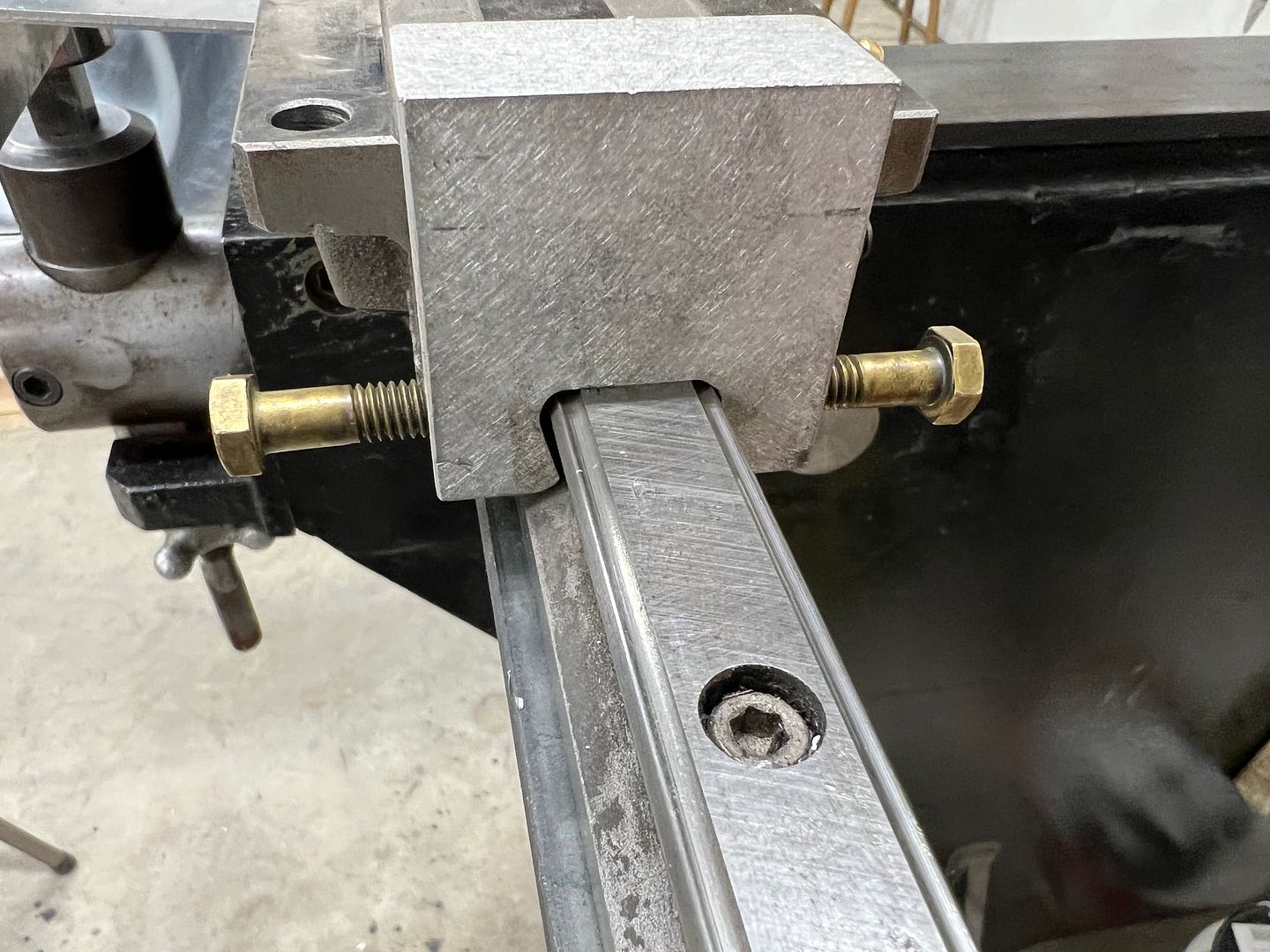

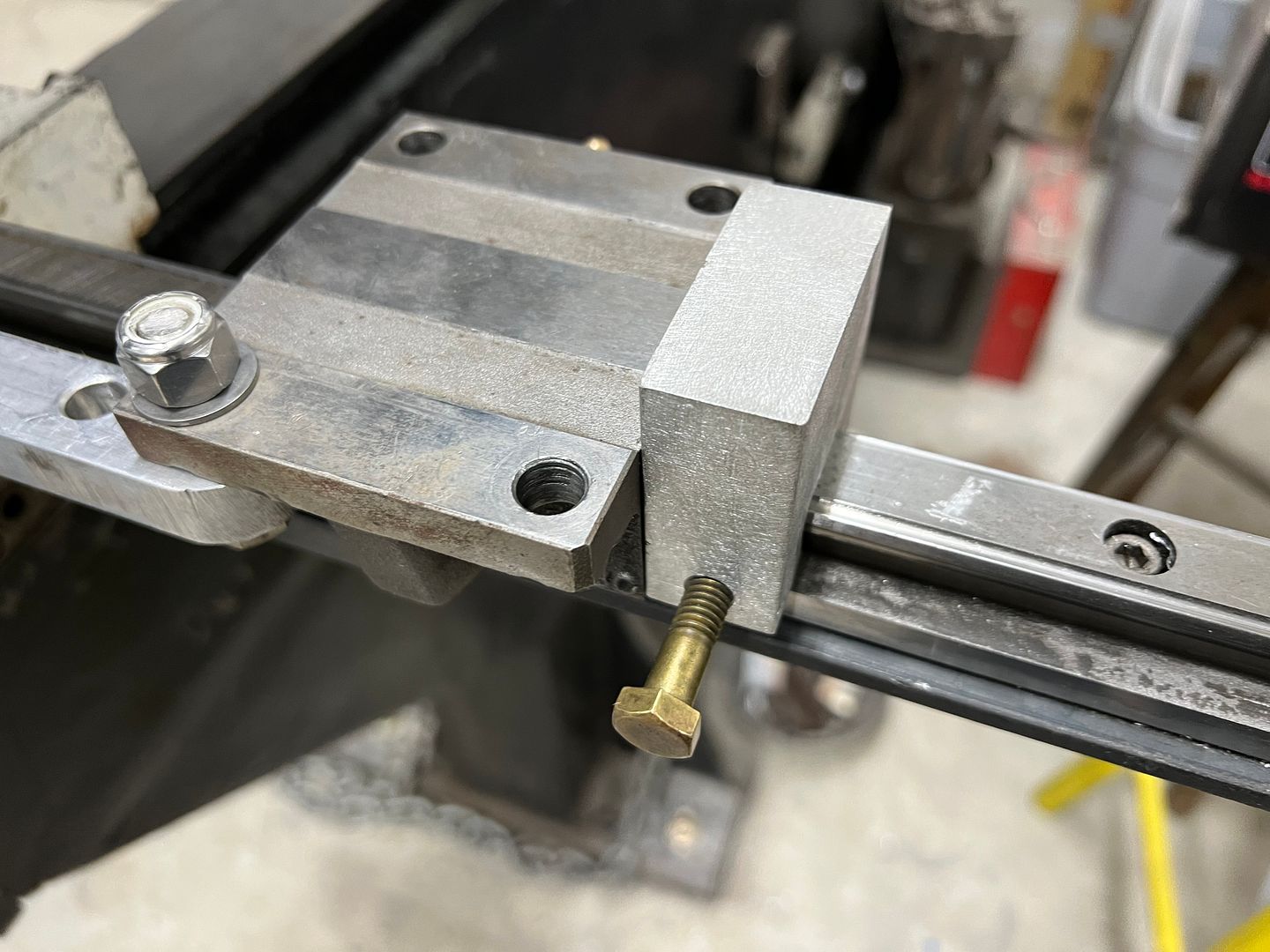

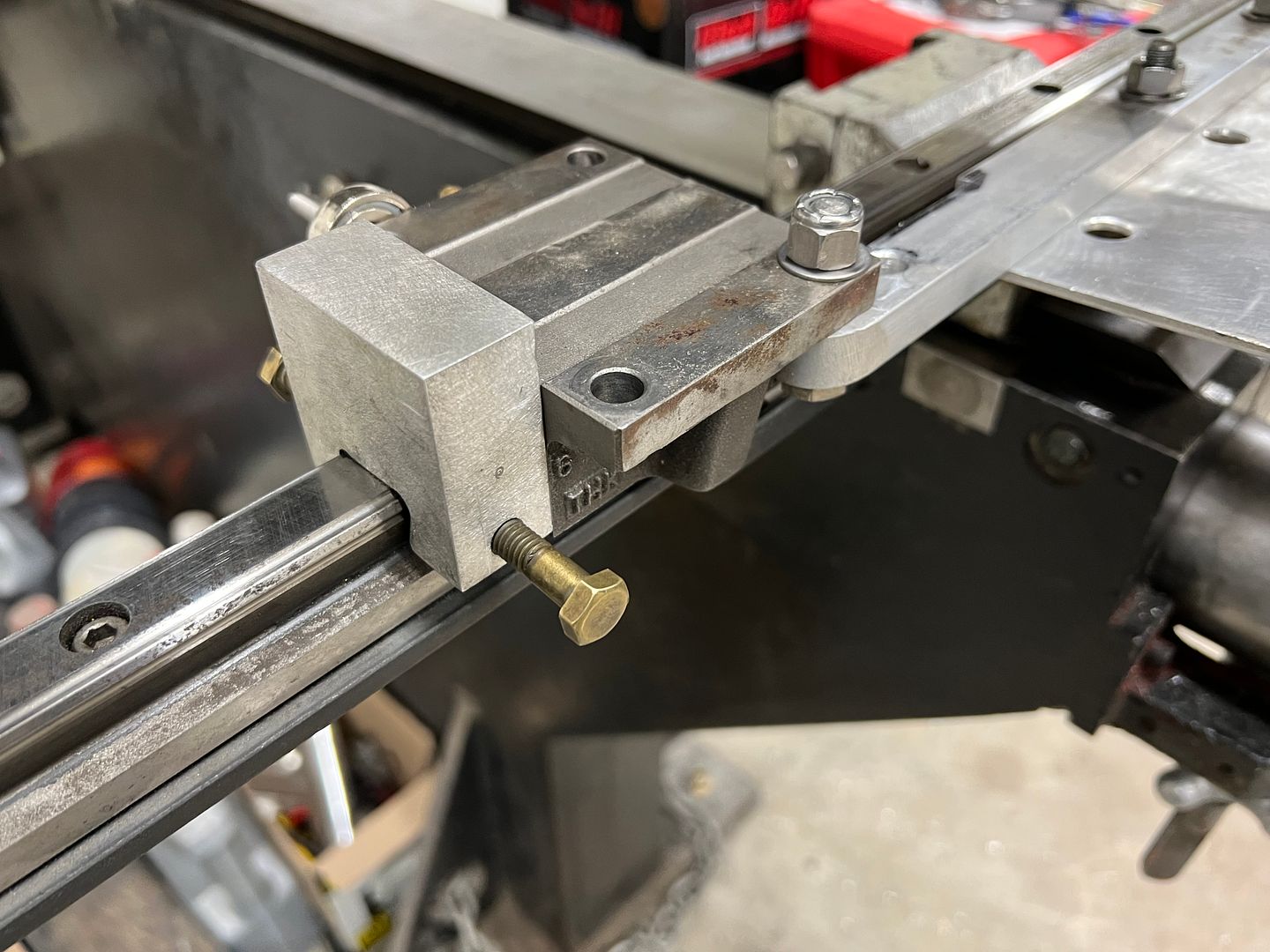

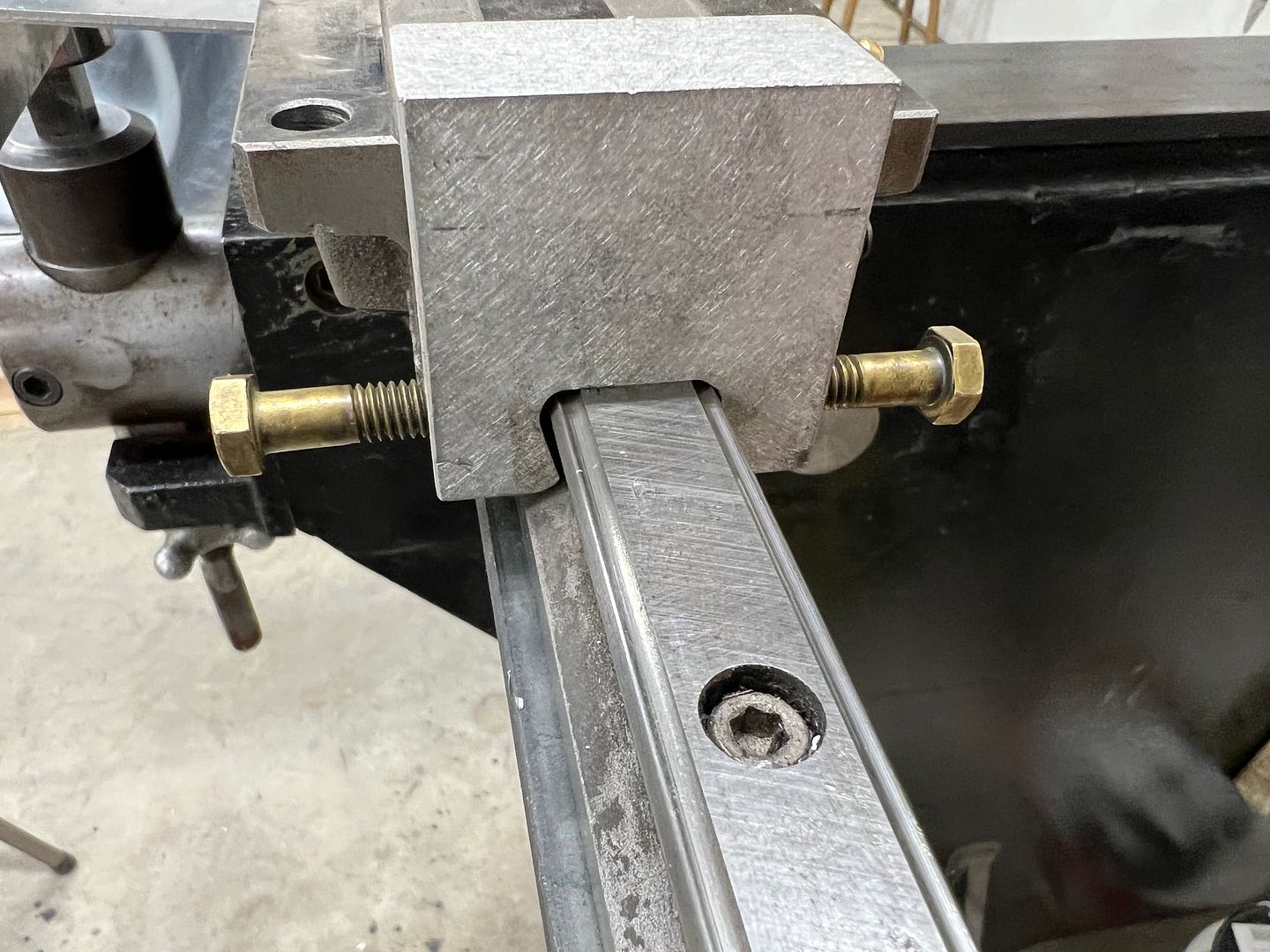

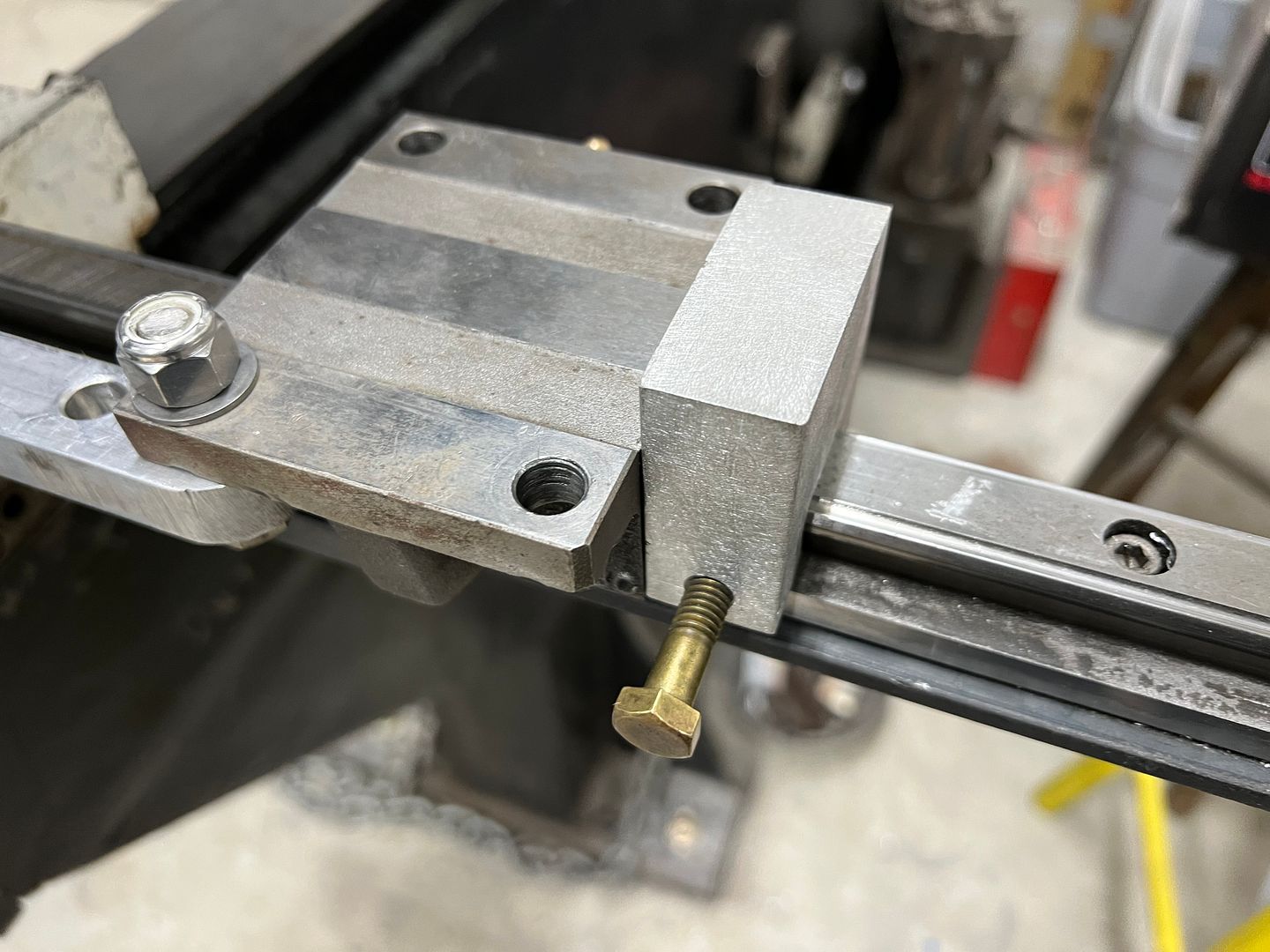

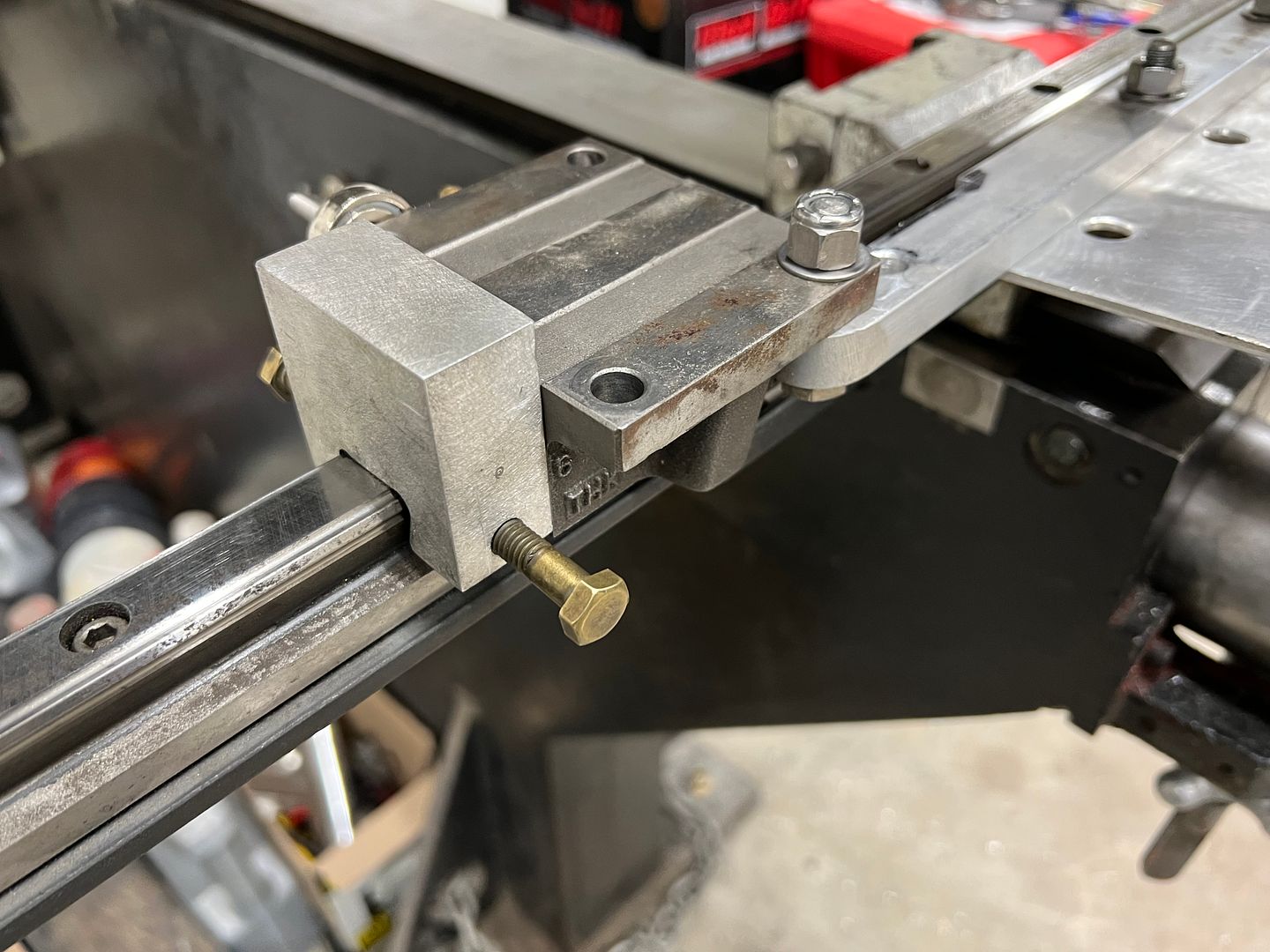

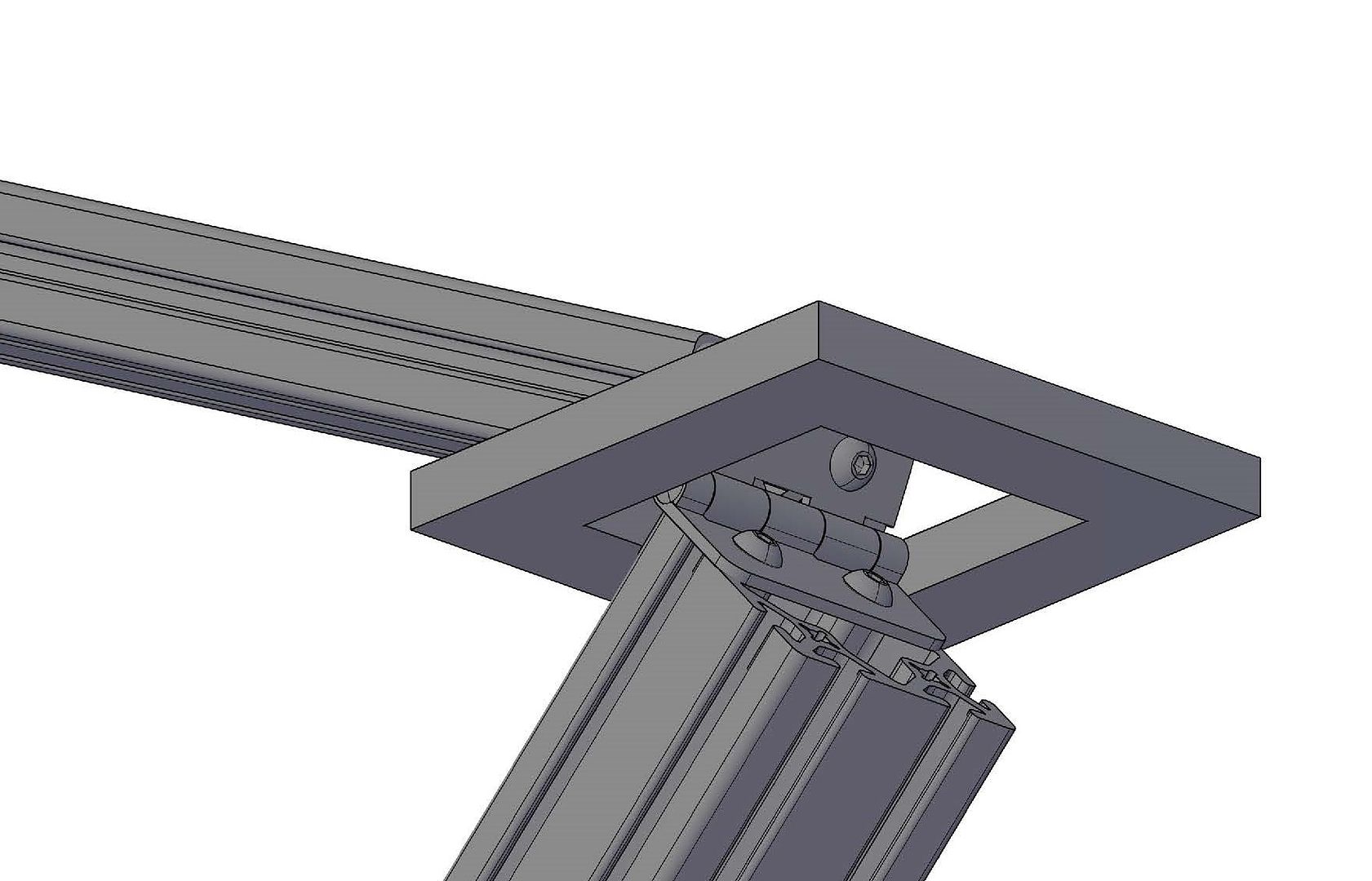

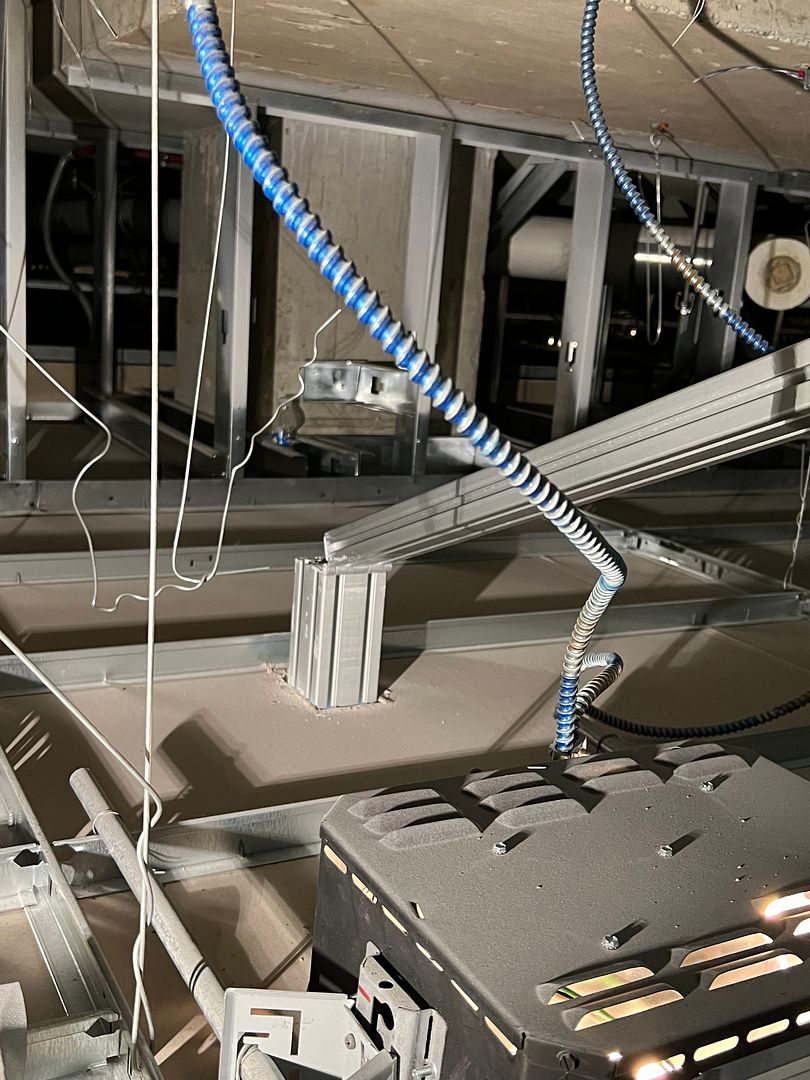

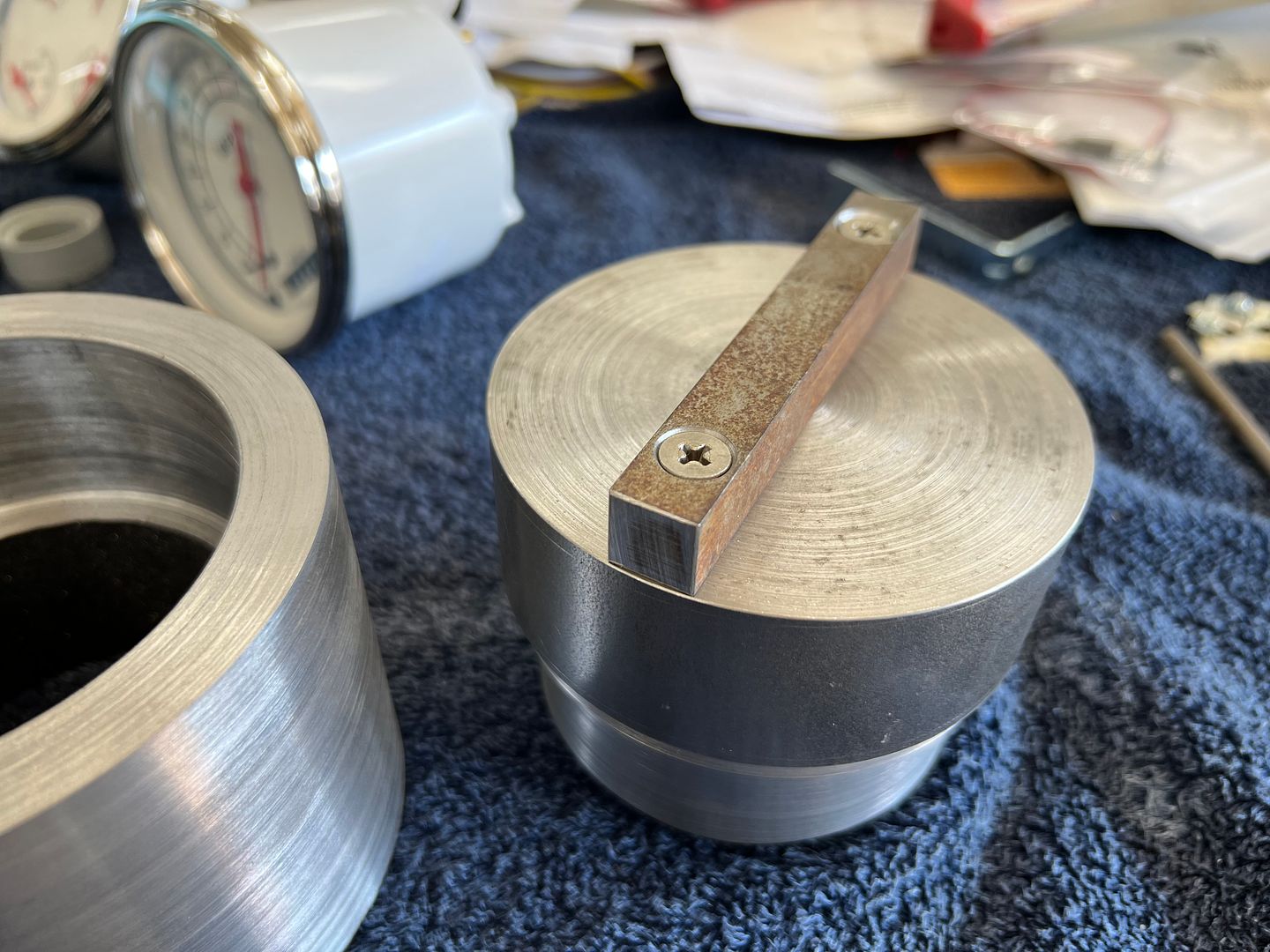

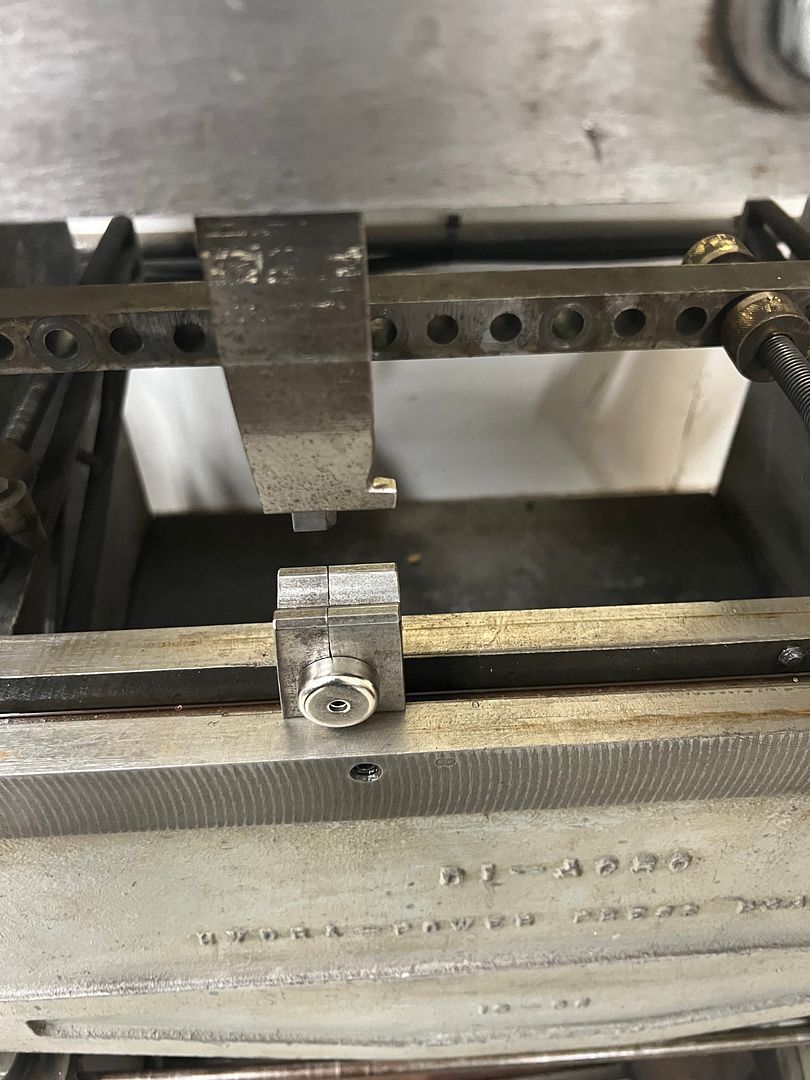

As this gets bolted to our linear slide and we'll need that to remain stationary, some Cerutti built clamp blocks are added.

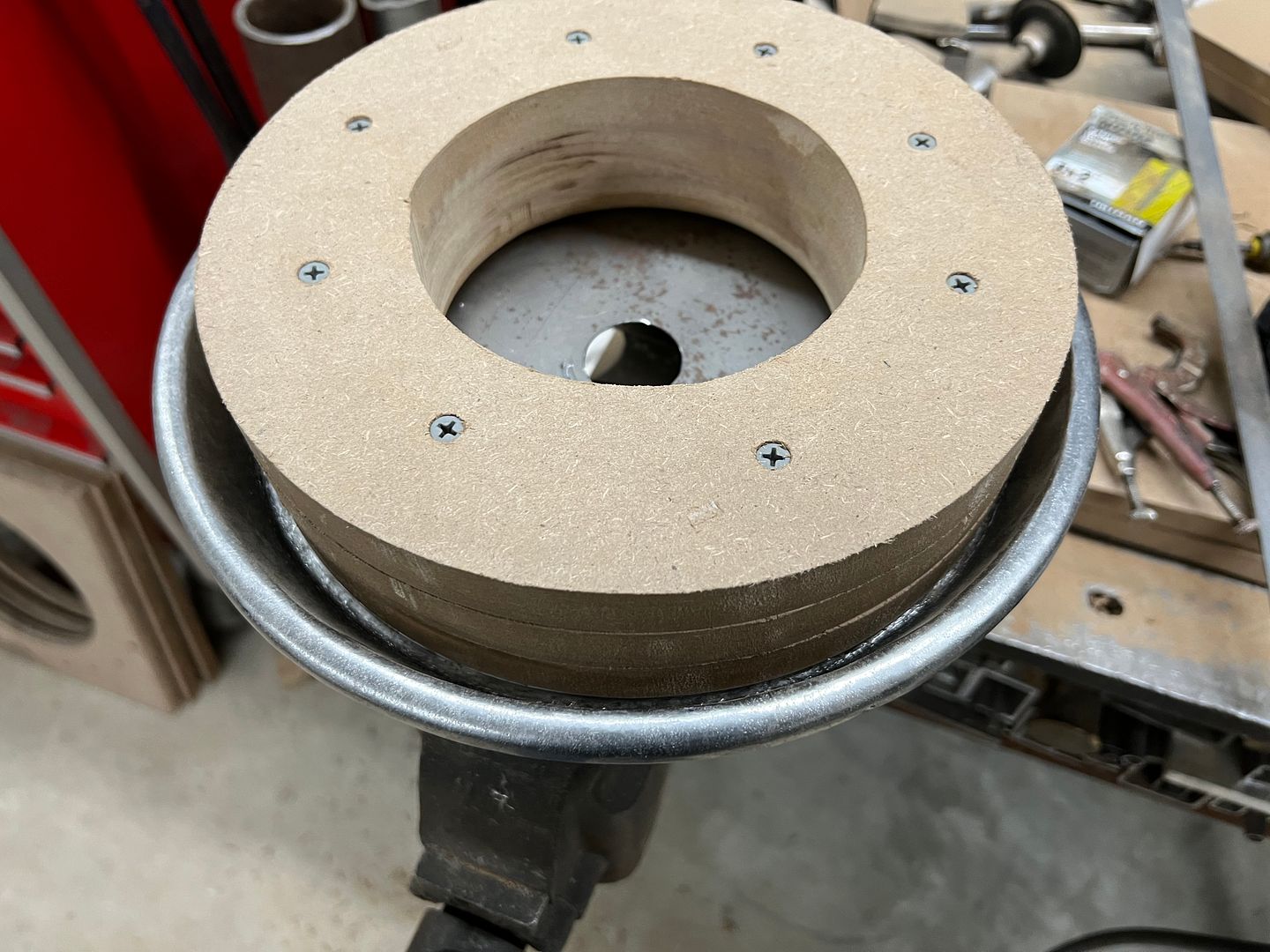

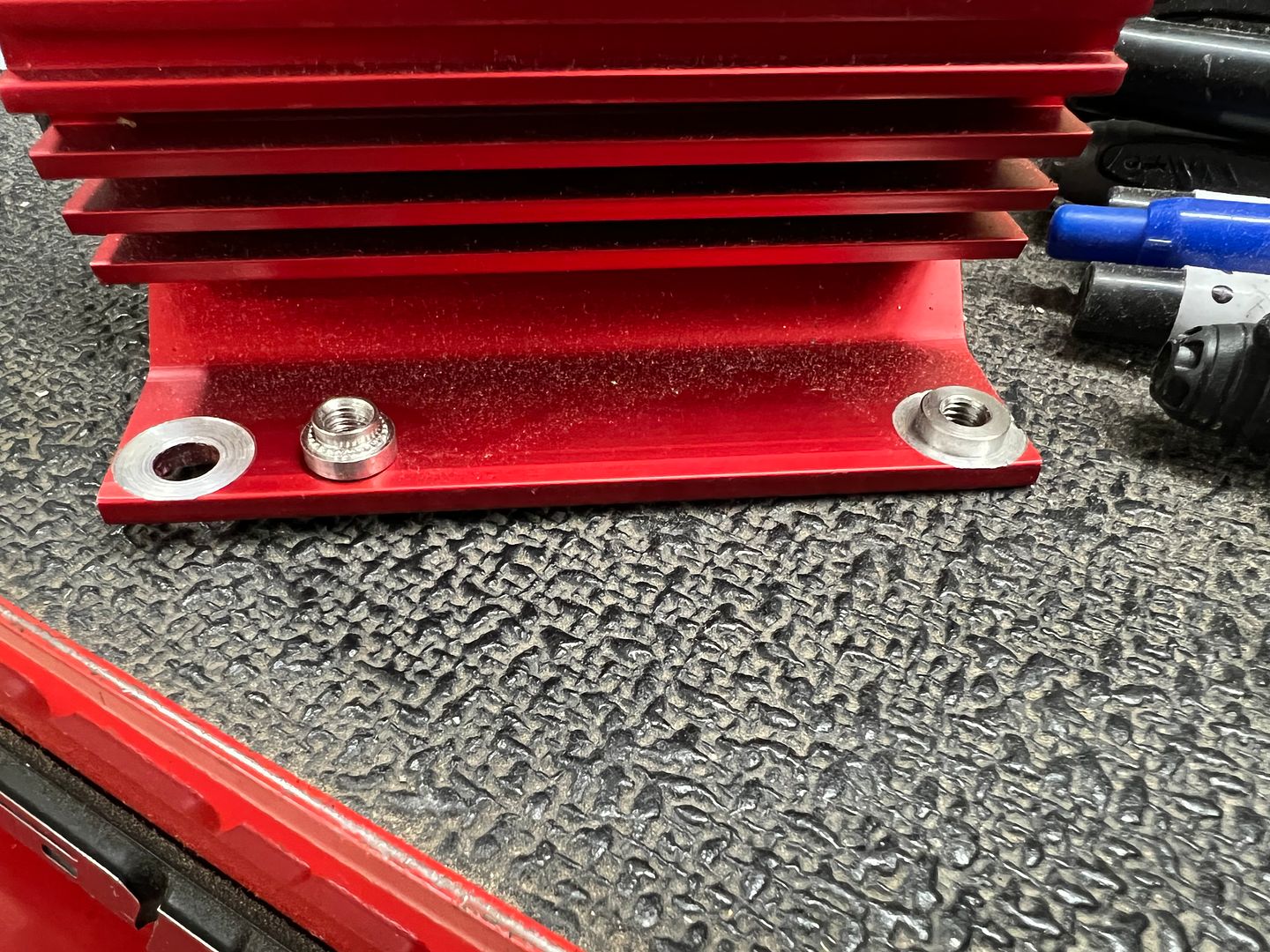

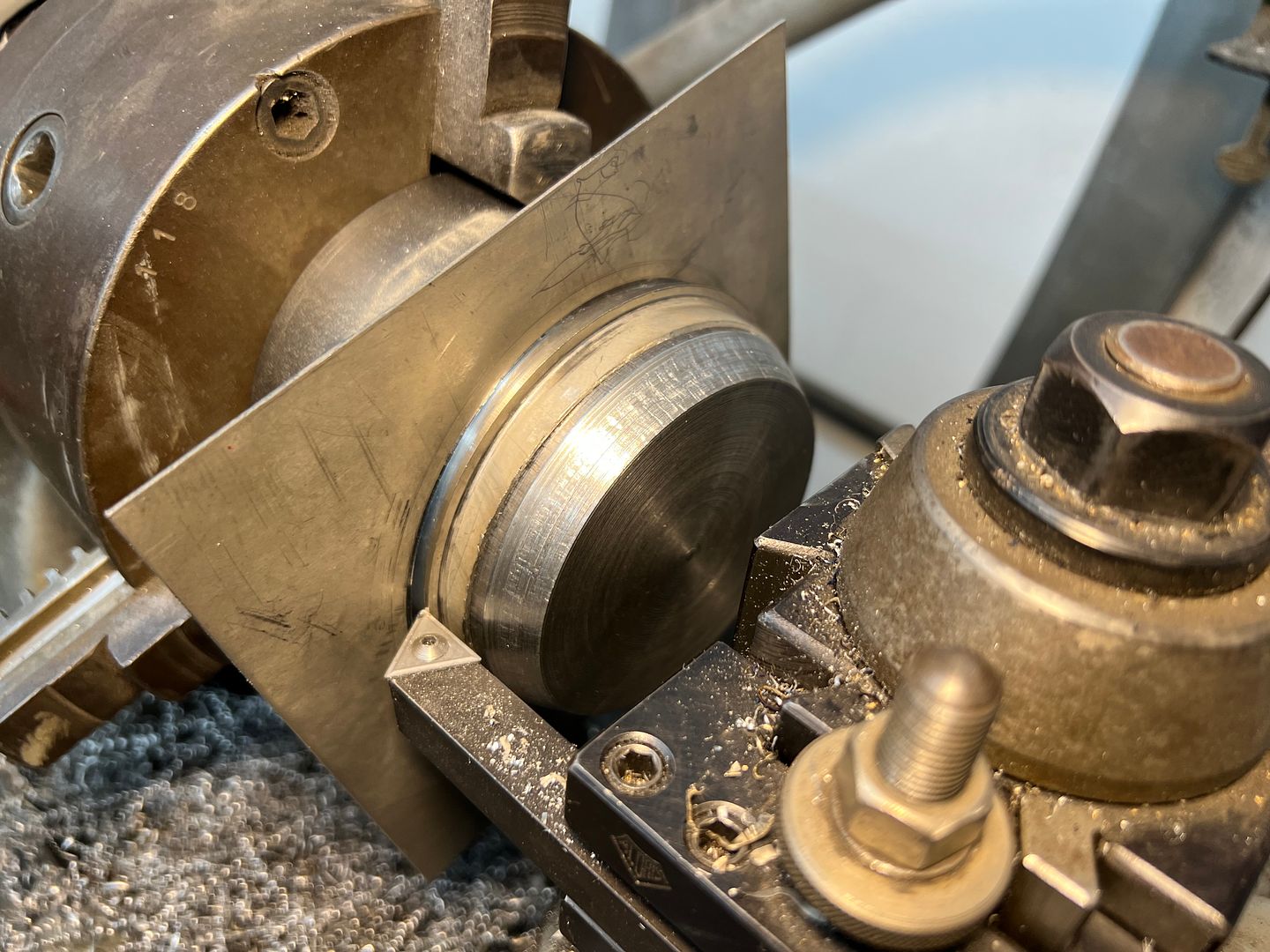

Linear stretch dies in action:

As this gets bolted to our linear slide and we'll need that to remain stationary, some Cerutti built clamp blocks are added.

Linear stretch dies in action:

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

Comment