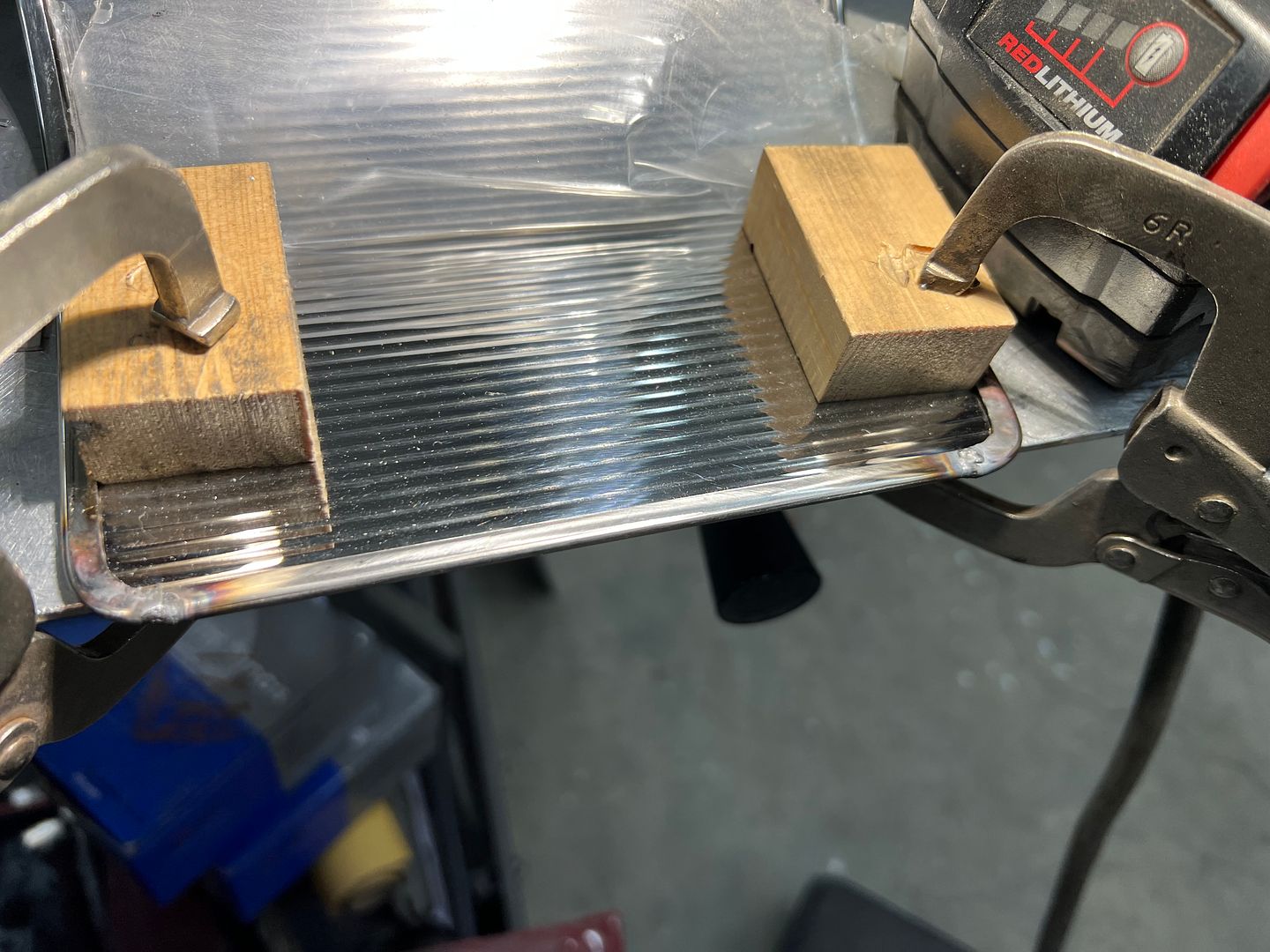

To close off the ends, we used the linear stretch dies in the Lennox...

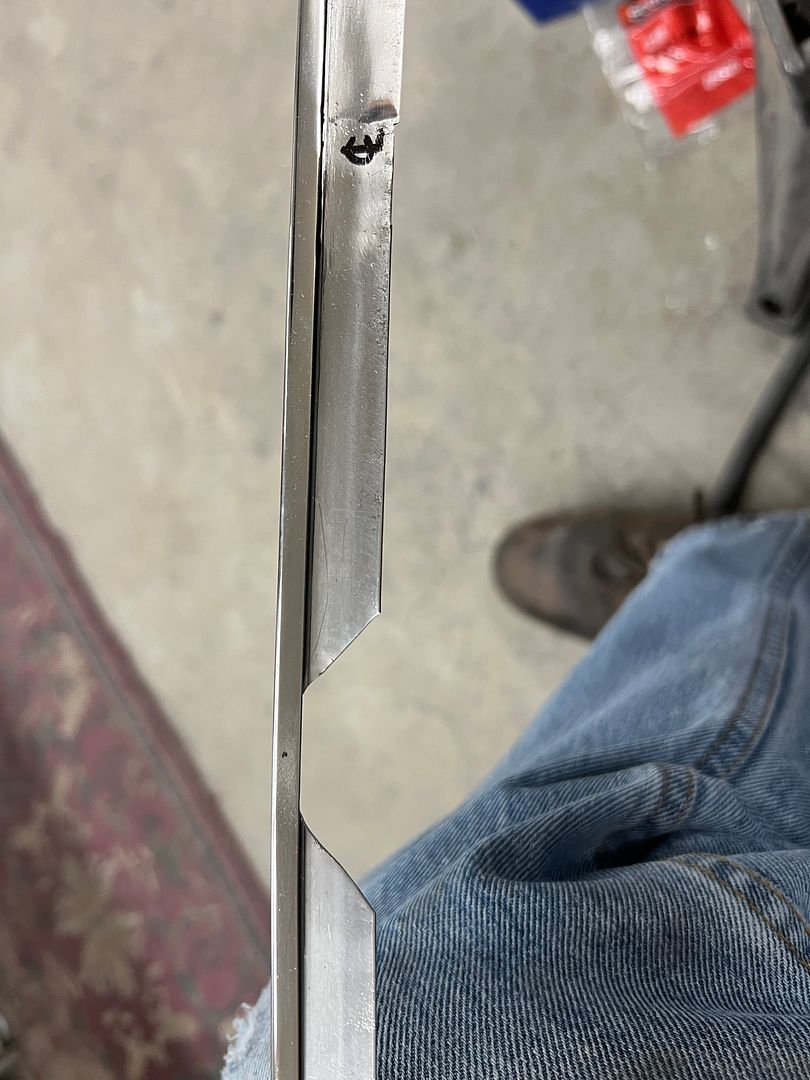

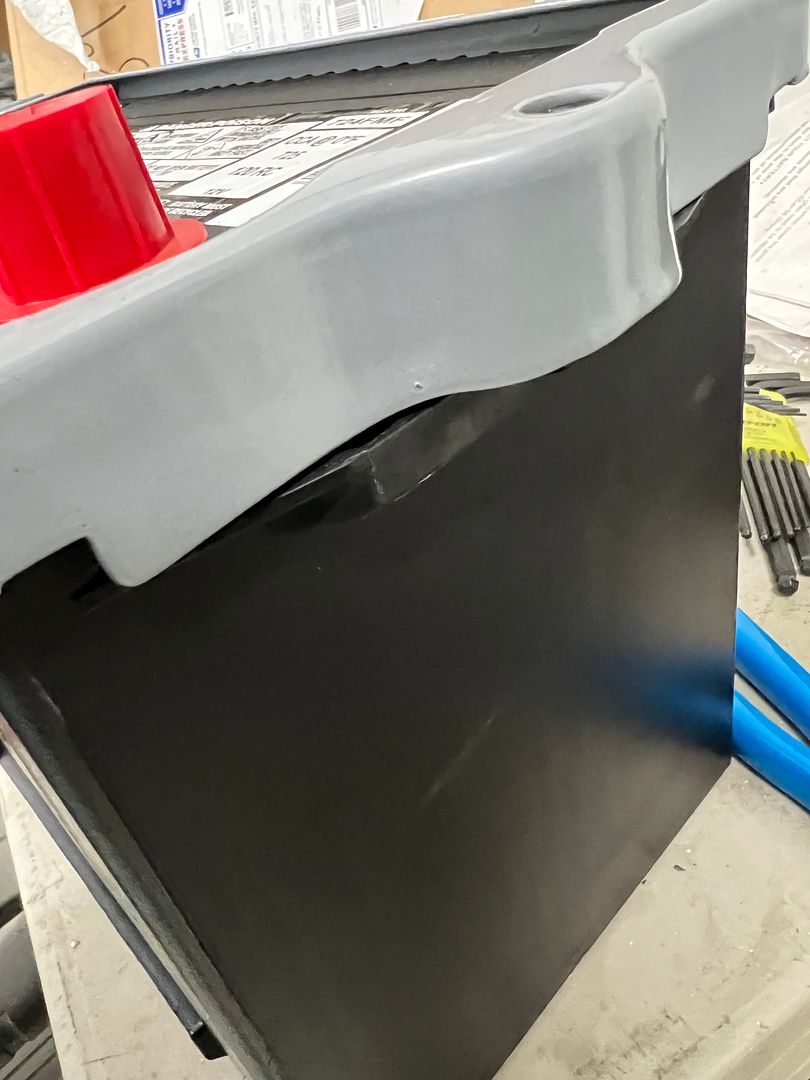

After welding the one end in place, the console was mocked up to get the overall length needed on the shifter seal.

The top flanges will be trimmed to the same width as our polished stainless edge trim surround on the console insert. This one will be used for the passenger side arm, the drivers side will have a wider flange toward the driver to accommodate the shift selector position marking.

.

_IMG_8985.png)

Leave a comment: