Not sure why I did it when I'm working on buying a house but I started nosing around the classifieds on www.Turbobuick.com looking for Stage 2 blocks (side note: Stage II was the 455 stuff of the early 70's vs. Stage 2 was the V6 racing stuff). I found this: http://www.turbobuick.com/threads/of...-block.443393/, a very well worn Stage 2 4.1 block (3.965in bore vs. a 3.800in bore for the 3.8 blocks) with a ton of issues but much much closer to my price range. I'm really debating it as a solid foundation that will take years, like everything else in this project, to make work but provides a MUCH more solid foundation than any production block. I'd have to sleeve it down to 3.700-3.800in bore to make displacement for my class but that would just make the cylinder wall thicker and more stable.

Help me evaluate this if you would.

PROS:

4 bolt center mains

Much thicker decks

Much thicker main webs (one of the biggest things about a Stage 2 block)

Siamese bores (a stock 4.1 block would have that too though)

6 head bolts per cylinder (stock is 4, added benefit is theoretically I could put studs in them without nuts and run Production then put the nuts on and run Modified since it's an "engine swap" by having more head bolts than stock)

Priority main oiling

Takes "GM" solid rollers without mods (stockers need shrouded foot lifters which aren't cheap)

Cost I can afford now/in the reasonable future ($500 when I asked yesterday)

CONS:

Missing front and rear main caps (which are about $450 for billet replacements, the rear is rarely upgraded on stock blocks as well)

One sleeve already and another needing to be put in

Already at ~4.045in bore and the thickest Manley replacement sleeves are 0.125in wall which makes 4.050in the maximum off the shelf sleeve I could find quickly so custom sleeves are in order

Has taken a hit before (hole welded and epoxied)

If it breaks, it would be harder to find a replacement for

Definitely needs more work than a stocker even if the stocker needs a full on rebuild (unless I sleeve down a 4.1 then it's close)

A stock 4.1 is around $600 for a complete engine but getting harder and harder to find. With a complete 4.1 I would get a marketable crankshaft (same as the turbo motors) but with the aftermarket forgings out there, its not as marketable as it once was and if it was rebuilt they are often swapped out for regular units so that's a crap shoot.

Thoughts on how good of an idea that block is?

Announcement

Collapse

No announcement yet.

(S//NP)3.0L Buick V6 Destroker Build (eventually an 81 Regal to put it in)

Collapse

X

-

keep going......on both the Rivera and this motor..."patience is a virtue, waiting is a pain"

Leave a comment:

-

This project has not died, it just doesn't get any money spent on it in areas that don't overlap with the Riviera since I'm still trying to get the Riviera to a Riviera Owners Association meet.

I have been researching the Bosch K-jet (CIS) system and turbos. What I have concluded is that I do need to run a pair of air meters and fuel distributors to make sure I have enough capacity for 350hp since I can't use any of the "normal" CIS tricks using the cold start injector. The Volvo/VW guys say those systems max out at 300hp with the cold start injector in the mix. I've made friends with a coworker with a 3D printer and we're developing plans on how to customize the air cones by machining the original aluminum cone off and bolting on 3D printed units. This should allow me to customize the fuel curve in the field by printing new ones in a hotel room. Because of this I want to use preferably the Audi turbo I5 units since they are

1. updraft (meaning the cone is on top of the air meter instead of inside like the Mercedes unit pictured earlier),

2. have a potentiometer built in so I can data log the air meter travel,

3. have individually adjustable fuel feeds to fine tune cylinders

4. have 5 fuel feed lines

The Volvo units will work (and can be a bit more common) but they don't have the potentiometer built in and have less fuel outlets.

The plan is to gang the extra 2 fuel outlets per head together and and have this common fuel supply run to each injector via a 'Y'. The individual injector lines will join at the 'Y' and give you your individual cylinder balancing since the bulk of the fuel supply will be the same to all injectors. This means I only have to run a single injector per cylinder which makes manifold fab much easier as I can get an EFI intake from an LC2 Turbo6 and just thread the injector bosses for compression fittings to hold the injectors.

Turbo wise I've been playing with Borg Warner's Matchbot turbo sizing tool as well as doing hand calculations and what really stings is the density altitude of Bonneville. The lower baro pressure means I have to run a much higher pressure ratio (i.e. more boost) to get the air mass I need. At least with a race only car keeping the charge cool and recovering some of that is much easier since I can ice the intercooler supply tank. Since I need a high pressure ratio and a decent mass flow I've turned to diesel turbos since they run big boost levels (even stock) and are durable pieces. The answer to my turbo question is basically a Holset HX35 or HX40 depending on if I want to buy headroom or just enough capacity. An HX35 will give me ~450hp worth of flow due to the crappy VE of the engine with the cam profile it needs. An HX40 probably has another 100-150hp in it.

Just documenting what's going on. Hopefully I get done with my Riviera soon enough to drag this project out for my guys night fellowship since it's more fun than doing basic fab and wiring.

Leave a comment:

-

All crated up!

Built the crate with casters so I can wheel it around to load up the parts and so the movers can easily put it on the truck here at the end of next month.

The crate is made of 2x4's with 2x6 uprights. The engine is bolted via 2 bellhousing bolts to the 2x6's with holes drilled partially through to fit the alignment dowels. I propped the front of the engine up on where the oil pan goes under the timing cover and is flat with a stack of 2x4's. The top is a storage box for things like headers, P/S pump, and other misc parts that came off of the engine that I don't want to scrap.

Now I just need to build another crate (without storage) for the Nailhead and it's matching ST400.

Leave a comment:

-

My men's group got back together now that summer has cleared a lot of kid schedule out off of our plates. Last night we knocked out tearing the heads off and rotating assembly out of the donor block (turns out it's one of the "bastard" 85's with a later oil pan but old deck height and so on which is an annoyance but not a crippling issue). Bearing looked great and the bores are nice and smooth. This motor has been well taken care of though like most Buick's it leaked and is externally covered in oily grime, I'll take care of that minimally before I crate it up.

Since the block is basically just a storage container right now I did total dirtball engine assembly, which is really more of parts consolidation. I reused the original main bearings since they weren't in bad shape and the crank needs a polish anyway before I could use it. Thanks to Scott Liggett I had a set of STD SBC rod bearings that I put onto the rods (they are weird Ford offset 6.300in SBC rods that work almost perfectly) and I put the pistons in with no rings since I didn't want to fool with trying to get the old ones off of the original pistons and I'm doing mockup work at best. Really the only thing I'm going to do to the motor after this besides put more fasteners in the heads and intake is to get a cast off Rover V8 timing chain to hold the oddfire cam in the block and put the roller rockers on the heads. Otherwise, it's crate time!

- Likes 1

Leave a comment:

-

While this has been totally backburnered for trying to get the Riviera ready for the Riviera Owners Association meet in June, I have made some progress on it in the name of consolidating parts to get ready to move with it this summer.

I have all the part I need to really put together a short block well enough to transport and I'll just throw the heads back onto the motor and the spare 4.1L 4bbl intake I have sitting around to seal it all up. I plan on getting the spare junk I have lying around off to the scrapyard this Friday to continue to get rid of stuff and make some money to put towards crating materials.

Minor change in the fueling setup is that I'll now be using Volvo 240t K-Jetronic air meters and fuel distributors since the bowl shape is different for the turbo motors and supposed to be more appropriate for a boosted motor. Another good thing about them is they seem to be more common than the 300E units I was going to use and they are blow up vs. blow down which should make packaging easier.

- Likes 1

Leave a comment:

-

Engine is a winner so I need to get rings, bearings, and wrist pins and it's off to the races to test fit everything then get the block final machined and the rotating assembly balanced!

I guess I really do need a cam and intake manifold but we'll get there.

Even better news is that the group picked up another guy who freely admits that "when I get bored I weld stuff and paint things" and he's my next door neighbor. Building a car is fun but the fellowship and friendship that is building is far more important!

- Likes 2

Leave a comment:

-

Big update

Got another engine, this time 68k mile granny fresh 85 unit and it's sitting in the garage awaiting disassembly and a plan for the other engine we have already.

I've also bought headers for the engine so once I get my turbo back from the shop we can start playing around with mounting it and other mockup steps with the old engine. We might even fire it after throwing it back together with whatever parts we have laying around and the minimum bought from the parts house.

- Likes 1

Leave a comment:

-

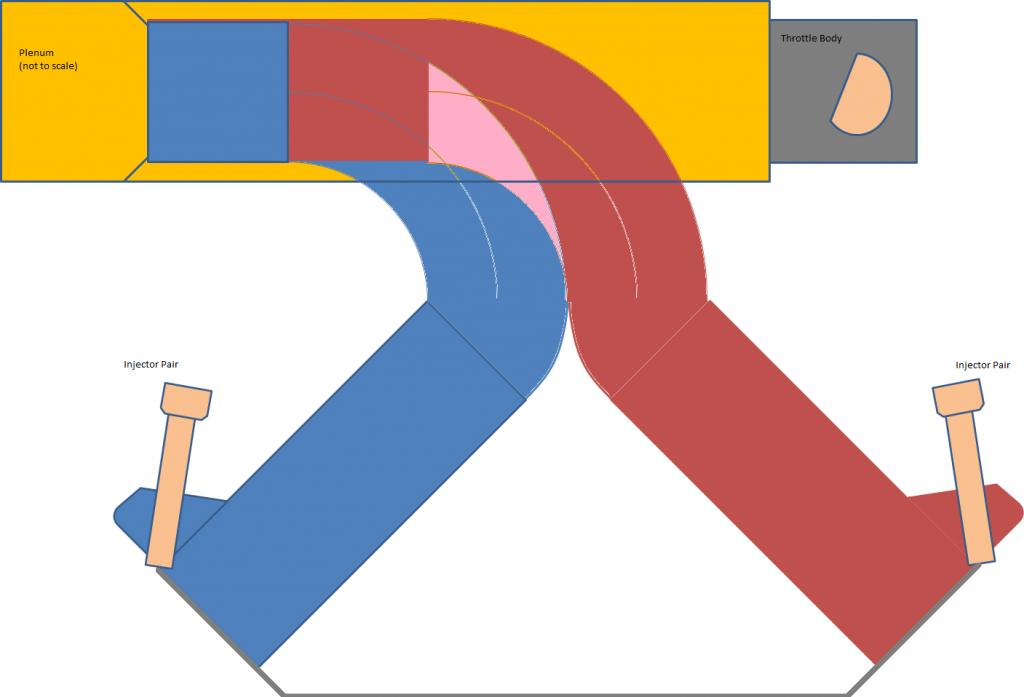

Intake idea modeled off of the Ford 5.0/5.8 intakes based on how relatively simple it is to fab, inexpensive in terms of parts, and a comment by someone referring to how a "93 Cobra intake is the only one I've seen that does a good job of equal distribution of air under boost" on www.turboforums.com.

It's made of 2in diameter tubing, 6 45deg bends and 3 U-bends cut in half to make the 90s. Depending on hood clearance I could bring all the 45's into a single line to lengthen the runners and make them all equal length. Plenum volume is going to be fairly big, roughly 4.5-6.0L with a flat back wall so the air coming out of the intake tube in the middle hits it smack on then distributes out along it.

- Likes 1

Leave a comment:

-

OPPS!!! The intake I have is for a low deck 3.0, not the tall deck which shares the same deck height as the 3.8. That means it's 0.5in too narrow a side. I might be able to fit the extra injector in that spacer but if I'm going to do that much fab, I might as well make my own intake from scratch... Plan to come.

- Likes 1

Leave a comment:

-

I've put used lifters in a different used cam. (during off season, no $$ coming in) in my flatbed.. Worked the snot out of it!

Cam's on the wall waiting for duty in a derby motor, maybe..

If the stuff is up to snuff.. Should be ok!

I wouldn't take that motor racing.. Just got too lazy to fix it proper..

Leave a comment:

-

All parties involved with the 79 turbo engine seem happy with the idea of the guy wanting the turbo plumbing to buy it and haul it down to his place, strip off what he wants and sell it to me for transport cost and a nominal amount for the parts.

Also found a guy parting out a 92 300E so I can get a complete AFM and FD off of it and start rigging up a test to run something with it.

How long do you think an engine would run if I put used lifters back in near randomly on a flat tappet cam? Really don't need the 3.8L to do much more than test if it will even start and idle with the injectors and intake on it and that the Rover oil pump will make pressure. With a miss matched neutral to external balanced damper I don't really want to run it under load, just rev it to see if the fuel system will actually respond.

Thoughts?

- Likes 1

Leave a comment:

-

Howdy,

So I have a hybrid Buick V6 Series II/Stage II timing cover on my Riviera that works great and gets rid of the wear prone spur gears, however it took quite a bit of work to make it fit and I had to customize quite a few things including chopping a pair of timing covers in half to make it work.

Rummaging around for small displacement motors for while I was bored/stalled on this project lead me back to the different generations of timing covers for Rover V8's. In 95 and 96 Rover made an "intermediate" timing cover that still took a distributor but used a gerotor oil pump. 97-~99 they used the same basic casting but instead boring the distributor hole (the hole is there, just not machined through) they used a sensor in the cover and a flying magnet on the cam gear. Now if I was making another one for my Riviera I'd be happy with the second one or even the later ones with the distributor completely gone but this is for (S//NP)'s motor that has to run old school with no EFI or DIS type ignition, so I snagged a cover from a 95 Discovery 3.9L

Fast forward two months or so and I finally got my first attempt at a usable block (didn't work out) for the 3.0L destroker.

Yanked the filthy with oil stock cover off and after wrestling with the drive gear popped the Rover cover on.

The good news is that it fits a 14 bolt pan like a charm, the stud is threaded into the timing cover through the pan, I did the other bolt hole after I took the picture.

The bad news is that Rover deleted a pair of the bolts around the water pump.

I knew they were missing however and it looks like with a bit of clearancing and the use of a Buick gasket, I can get them to seal fine with a plug or maybe a set screw of some kind.

I also grabbed the balancer to get the waterpump pulley to line up and it's neutral balanced, perfect for an aftermarket crank like what I'll be using.

I also found a 79 Turbo6 for sale on Craigslist, too much at first glance but no harm in finding out if I'm going to pay $450 for another engine full of what will be mostly spare parts to avoid $1000 on pistons. Called the guy up and turns out he has a guy in the town South of me that wants the turbo and associated intake, plumbing and electronics, exactly what I didn't want off of it. The seller is trying to sell the other guy on pulling what he wants off and selling me the block and everything else that's left for $100-150. I'll take it! We'll see how it turns out.

On some related sad news, the Black Forest wildfire claimed the entire property, shop included, of Loophole Racing which was a Buick Indy Lites team based in the local area. Big loss for them and the community.

- Likes 1

Leave a comment:

-

Haven't run across really anything but out here!

I need a STD bore preferably 77-early 85 3.8L since the 3.0's had FWD bellhousings, the 3.2 has a 3.5in bore, and the 4.1 has a 3.965in bore. I've had trouble finding any engine in that range to be honest, I bought the first one that was for sale in town at a reasonable price considering all I really needed was the block but never hurts to have all the miscellaneous nuts and bolts on a complete engine.

- Likes 1

Leave a comment:

Leave a comment: