Originally posted by 68scott385

View Post

Announcement

Collapse

No announcement yet.

The War Wagon... decaring wars on the grocery store since 1966

Collapse

X

Collapse

-

I bought it from some dude who had it in his 32 ford. I cant remember how he said he had the overdrive wired. I think he said he had it on a switch. I really cant remember though.

-

Who supplied the transmission? My 700r4 came from TCI and the only control over the lockup convertor is a vacuum switch, 12v source, and a ground wire. The 12v & ground wires can be run through switches. I'm sure I have the directions if you want me to scan/post them.

Leave a comment:

-

Got stuff done! pictures!

taking the drive shaft off to the machine shop, cleaned it up before it went into the back of the mustang. should be back in a couple days

a little blurry, but here is where I mounted the dipstick for the trans. It came free with my transmission and it does the job, its out of the way, and easy to get at. ignore the blue tape thats just holding that wire out of the way until I can get a clip to secure it

the Lokar shift linkage showed up, had to trim a few inches off the bar to make it the right length and had to play with the shifter selector arm a few times to get the positioning right, but it shifts into all the gears with no binding. its nice and smooth and the needle even sort of lines up with the letters on the column indicator. I put a light bend in the bar too but overall its strong sturdy and fool proof.

might be the nicest thing on the car right now.

I am quite happy with myself, I will be able to finish it up in a couple weeks after the next pay check

as for budget...

previous cost 5,102

added expenses

quart of trans fluid to fill converter $6

Lokar shift linkage w/shipping $69

distributor kit $70

assorted hardware $5

driveshaft $275

total build cost so far

$5,527

things left to buy to finish up trans swap

TV cable kit from Bowtie overdrives

TCI overdrive controller

Trans filter

drain plug kit

gasket/fluid etc

trans cooler lines/fittings

aux trans cooler

tachometer

Last edited by Shelty; June 6, 2014, 05:12 PM.

Leave a comment:

-

dropped the driveshaft off to the machine shop, they are going to make a new one for me instead of using the old one. gave them the length, so they should take care of me. should be done in a couple days too.

Fedex didnt deliver my linkage today, which it typical. when UPS ships something from summit, I got it in two days, Fedex, well I hope its here tomorrow.

going to have to wait till next pay to order the last bit of parts, but its getting there.

I just cannot wait for this car to be done. will have some pictures up tomorrow.

- Likes 1

Leave a comment:

-

no pictures of the boring stuff I did today.

found a machine shop that may be able to take care of the drive-shaft, going to measure it again tomorrow and take it over there.

got the few bolts I needed for the bell-housing, got them bolted in and tightened. got the starter back in and hooked back up.

most importantly, I got the issue with the transmission cross-member fixed. had to extend the holes in the mount that bolts to the transmission, maybe a 1/8th of an inch, and had to enlarge the holes on one side of the frame mount a tiny bit and that did the trick, the transmission crossmember is now bolted in tight.

was also going to mount the transmission dipstick, when I bought the transmission, it came with a lokar braided stainless/flexible dipstick tube. found a good spot to mount it to the firewall, just need to drill holes for it, but I cant find my bits, I think the last time my parents came to visit, my dad and I were working in the garage, think he might have grabbed them by mistake.

the shift linkage should be here tomorrow

Leave a comment:

-

have not been out to mess with the car the last couple days. I need to get out and pick up more bolts for the bellhousing, two were too short to use. also will go get some self tapping screwed, found a place to mount the dipstick on the firewall.

ordered a lokar shift linkage should be here in a few days.

also my Cpl told me of a place a couple miles from me that will do a custom exhaust system for 300 bucks. its worth looking into, I can always drive the car up there open headers.

Leave a comment:

-

yeah, its not a super huge issue. another idea I had was to see if I can center the crossmember under the trans, and if I cant get the bolts to work where it bolts to the frame just weld it. i'll figure it out

Leave a comment:

-

pretty much. its two bolts on each side of the crossmember, then there are supposed to be two bolts that bolt the trans mount to the crossmember. but I'll figure it out one way or another. its hotrodding, either it fits or you make it fit.

- Likes 1

Leave a comment:

-

5 bolts, a 2x4 and a jack... sounds like a good next step, and priced right!Originally posted by Shelty View Post...

one thing I didnt try was centering the crossmember under the mounting pad on the trans, then see where the holes where it mounts to the frame line up. I could always take a crack at that after work one of these days. I just need to get motivated to order the next set of parts. probably do the linkage for the shifter next

Leave a comment:

-

they do, but no matter which way I move it, the cross member does not go far enough to be of any good. I thought about elongating the holes even more, but that thing was such a pain in the butt to get into the car, Im surprised I was able to get it in to begin with. I dont want to modify the bracket that the crossmember bolts the one welded to the frame rail. the only thing aside from the cross member mounting pad being off centered is that, it appears that the Driver side bracket on the frame rail had been re welded at some point. it could have possibly just been rewelded in the wrong spot. there are several hinky places on this car that has me head scratching, I'll just have someone look at it when i get it back together. once I get everything tight, it will be good enough to limp down the road to get fixed. my goal is to have it back on the road in july.

one thing I didnt try was centering the crossmember under the mounting pad on the trans, then see where the holes where it mounts to the frame line up. I could always take a crack at that after work one of these days. I just need to get motivated to order the next set of parts. probably do the linkage for the shifter next

Leave a comment:

-

Do the frame ends of the cross member have elongated holes? Maybe you could slide the cross member laterally to get the mounts to line up. Just a thought.

Leave a comment:

-

i think it may have taken a bit more than a wagon lol.

anyway back to my wagon.

good news. the trans is in. finally.

extremely tired but its in. didnt really take much to wrestle it in. I need to go get more bellhousing bolts, like two more, cuz the two top ones were too short, the case on the 700 is thicker than the PG. I also have a billion other things to buy but at least the heavy lifting is done

I had to cut the center of the "H" out on the H-pipe out in order to slide the transmission up into position. the exhaust is going to be modified/changed anyway, so I didnt feel too bad. it wont take much to weld it back together so no real bit worries.

\

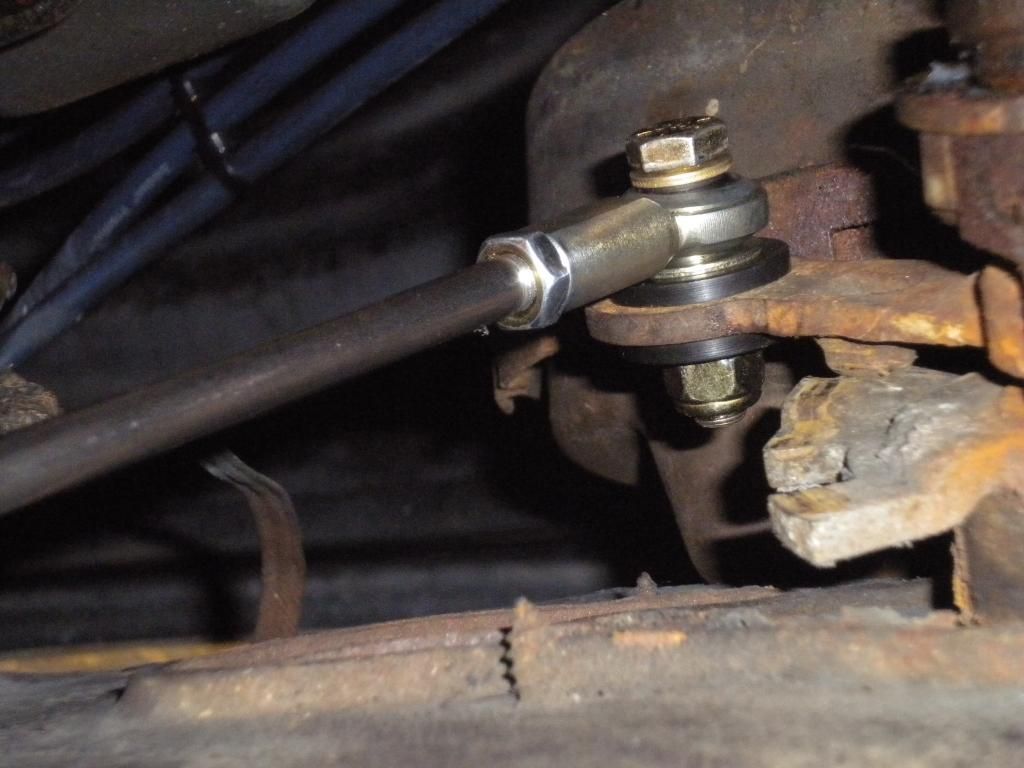

Bowtie overdrives crossmember.

luckily, I know the old saying with hotrodding in that nothing is 100% bolt on. although the bow tie overdrives crossmember is very nice, the mounting point on the crossmember for the transmission is not 100% centered, so with some finagling and some loc-tite, I managed to get one bolt into the rubber mount that bolts to the crossmember for now its good enough for me to limp the car to a shop, have them cut and weld the bracket about half an inch over. Im pretty sure the crossmember is the issue, as the trans is bolted up to the engine, the engine isnt at some strange angle.

but on the bright side, the torque conveter and the flexplate bolted up perfectly fine to one another.

but im done with it for a few days until the next paycheck comes in, I was going to do more, but my buddy came by with his corvette so we went cruising and went to Hooters. damn that 'vette hauls ass. I never was in a corvette before.

Leave a comment:

-

Its all relative...............took a wagon to haul that sucker home!

Leave a comment:

-

we had a Panasonic (1976) that opened like a clam ... how bout this mutha?

1962. Those feet probably poked through linoleum. Maybe the title shouldn't say Grocery and I'd quit derailling the hell out of it. Ooooops. Sorry. Back to the wagon!

Leave a comment:

Leave a comment: