Continuing on with the same story

I didn't like how the driver's side looked like the first time, so I cut it back apart

and started again

last night got here

unfortunately, these had to come out

and only one runs... story of my life.. in case any of you wonder why I need 5 off-road vehicles... there it is

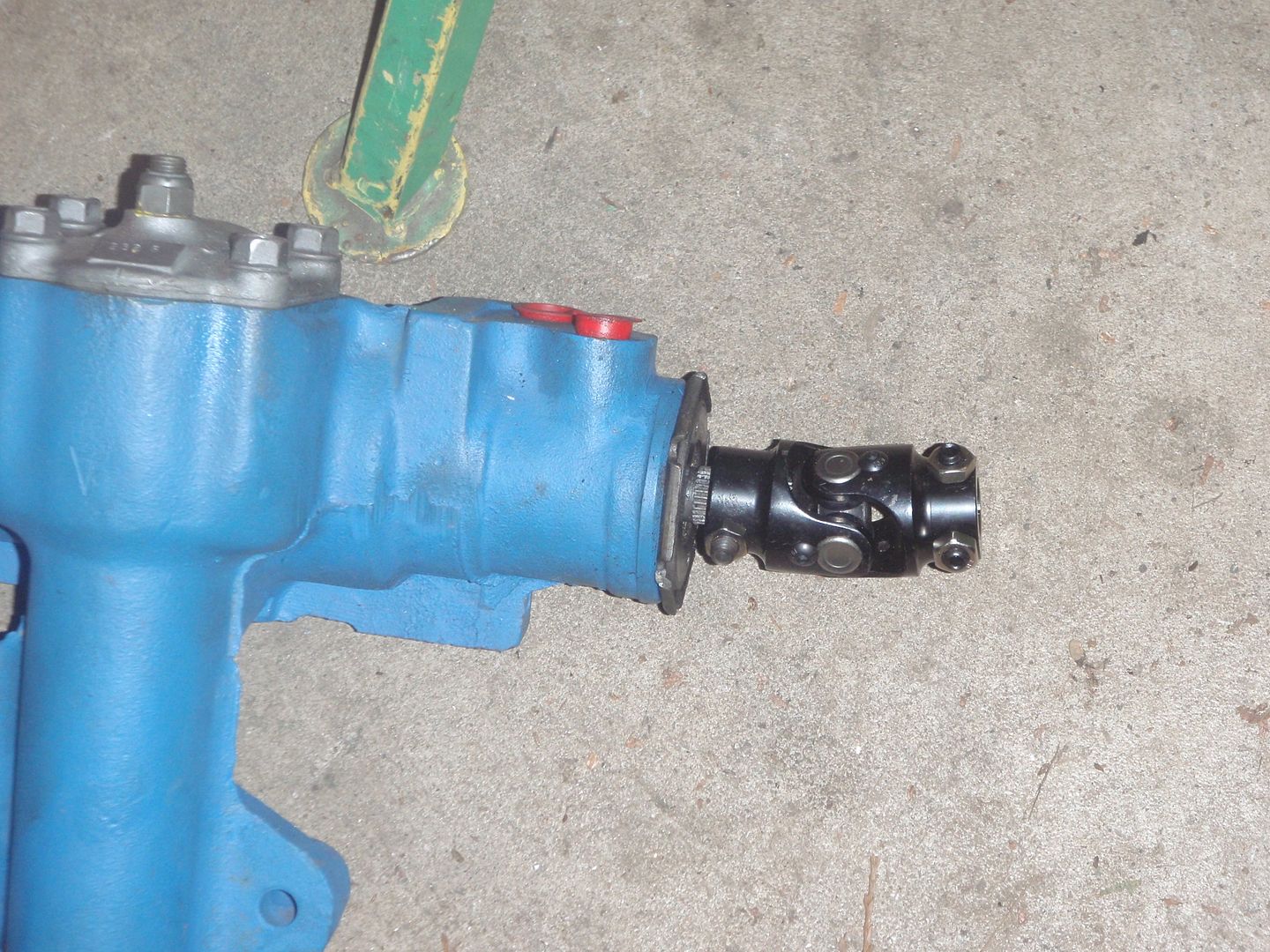

finally starting to put this part together

so at the end of tonight

and I bought a 14 bolt for parts... yeah, I bought a 14 bolt rear end for parts for a dana 60... I know it seems like robbing speed parts from a 911 to made VW bug faster... but there is method to the madness

I didn't like how the driver's side looked like the first time, so I cut it back apart

and started again

last night got here

unfortunately, these had to come out

and only one runs... story of my life.. in case any of you wonder why I need 5 off-road vehicles... there it is

finally starting to put this part together

so at the end of tonight

and I bought a 14 bolt for parts... yeah, I bought a 14 bolt rear end for parts for a dana 60... I know it seems like robbing speed parts from a 911 to made VW bug faster... but there is method to the madness

Comment