Spent today hosting a Pullmax Workshop for some of the guys from the VA HAMB. OJ Higgins recently took delivery of a gargantuan Trumpf universal machine (a Pullmax on Steroids) and wanted a down and dirty on how these machines could be put to use. So OJ and a few other VA guys stopped by today and for a sample to use, ClutchDumpinDan brought by a tail pan from his 52 Chevy that was in dire need of rust repair.. We found a piece of 18 gauge cold rolled steel large enough to do the trick, so Dan cut it in half just in case we needed to do this twice...

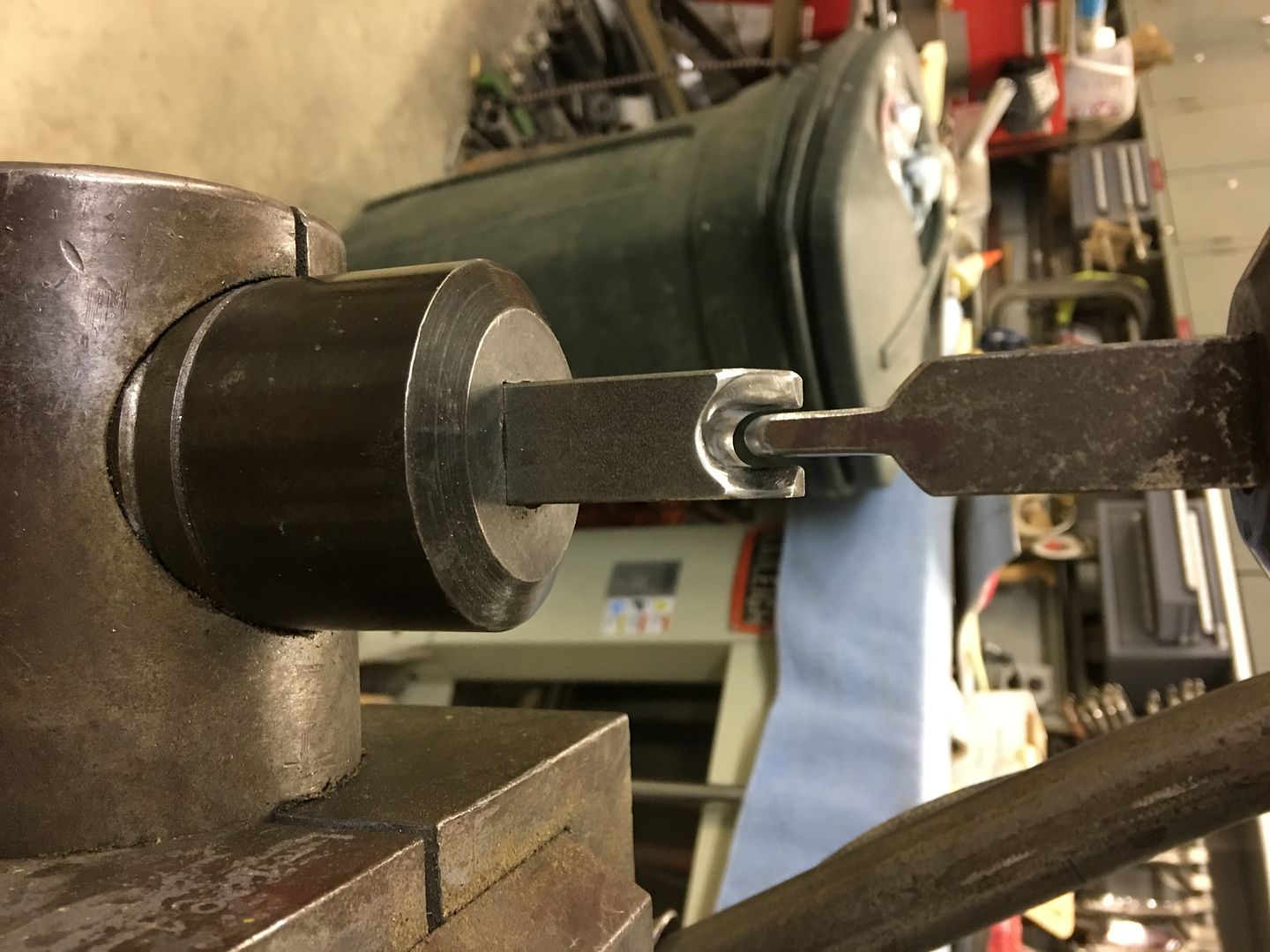

Dies made for the universal tool holder in the Lennox Nibbler

Profile check...

Test sample...

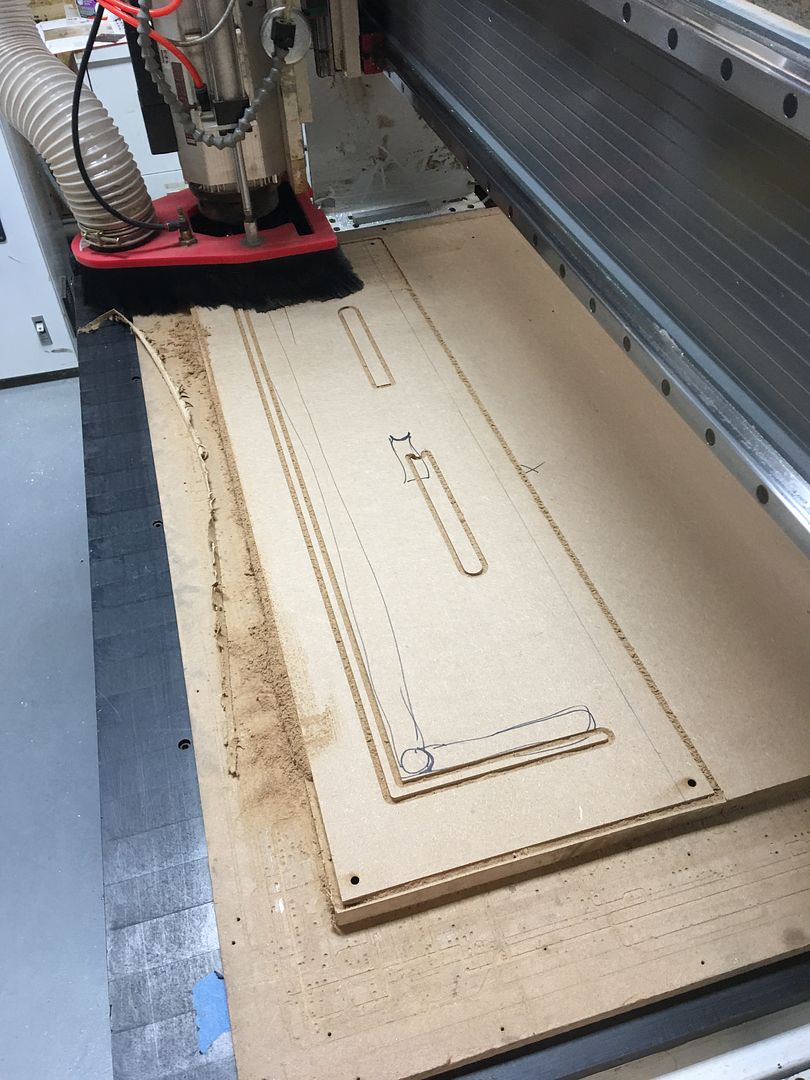

Our new panel ready to run through the dies...

Step detail

Tipping the leading edge..

Dan takes a twinkie break

Videos....

Comparing new to old...

Rusty seal joggle on the old panel...

The new one...

Adding some bead details to change things up a bit...

Comparison....

Fancy tool for finishing the bead ends...

Dies made for the universal tool holder in the Lennox Nibbler

Profile check...

Test sample...

Our new panel ready to run through the dies...

Step detail

Tipping the leading edge..

Dan takes a twinkie break

Videos....

Comparing new to old...

Rusty seal joggle on the old panel...

The new one...

Adding some bead details to change things up a bit...

Comparison....

Fancy tool for finishing the bead ends...

Comment