The falcon tank, like mustangs, has the fittings in the front lower portion of the tank - so that fitting would be swimming in liquid fuel all the time. I'd want a fuel safe O-ring on that fitting. If going into the top of the tank (which is the trunk floor in a mustang/falcon/cougar/etc) I'd be less concerned.

Announcement

Collapse

No announcement yet.

Can a caveman do DIY EFI? Nothing ventured, nothing gained...

Collapse

X

-

I'm making a list of things to purchase for the next steps on this project. Relay board, cables, Coolant temp sensor, Intake air sensor.

Just pondering about springing for the LC-1 wide band at theis point. Why would I NOT buy the Innovate standalone guage kit? For a few more dollars it comes with an $89 guage (which could be used on other stuff with no MS on it)

Get your Innovate Wideband O2 Standalone Gauge Kit including the LC-2 + Blue DB Gauge at DIYAutoTune.com!

Get your Innovate Wideband O2 Standalone Gauge Kit including the LC-2 + Blue DB Gauge at DIYAutoTune.com!

Here is the one with no guage for just a few dollars less.

The LC-2 takes Innovate's award winning wideband AFR hardware in a small, waterproof enclosure. This is a complete system without gauge.

The LC-2 takes Innovate's award winning wideband AFR hardware in a small, waterproof enclosure. This is a complete system without gauge.

What am I missing? Why wouldn't I want the Guage one? They seem to be the same to me otherwise.Of all the paths you take in life - make sure a few of them are dirt.

Comment

-

If you can find it without the gage for $140, then it would be worth getting without the gage. But yeah, it would be nice to have the gage too.My fabulous web page

"If it don't go, chrome it!" --Stroker McGurk

Comment

-

Can I get by with the single sensor, even if I am running headers with dual exhaust? I was thinking I could tune with the sensor on one bank, and then check by moving the sensor to the other bank.Of all the paths you take in life - make sure a few of them are dirt.

Comment

-

Gotcha. Just like boost referencing will deliver more fuel according to barometric pressure in the intake manifold.Originally posted by dieselgeek View PostFor an MPI system you should run a vacuum referenced regulator. It makes sure that the pressure differential at the tip of the injectors is always the same. So if you are pulling 20" of vacuum at low throttle/load, the regulator will take the fuel pressure down 20" - so you always get the target ~40psi difference between fuel pressure and manifold pressure.Of all the paths you take in life - make sure a few of them are dirt.

Comment

-

Sorta, except that Barometric pressure moves in super small increments, like 1-2 kpa range. The manifold pressure will move as much as 80kpa on an N/A engine, and 200-300kpa on a boosted engine, all this depending on throttle position/load.Originally posted by STINEY View PostGotcha. Just like boost referencing will deliver more fuel according to barometric pressure in the intake manifold.

And yes you are fine with a single sensor. Tune the engine on one bank, leave it safely rich so any lean cylinders don't hurt themselves.www.realtuners.com - catch the RealTuners Radio Podcast on Youtube, Facebook, iTunes, and anywhere else podcasts are distributed!

Comment

-

I only have one in the driver's side header and have never moved it. Making the jump to sequential soon, my MSIII shipped today....Originally posted by STINEY View PostCan I get by with the single sensor, even if I am running headers with dual exhaust? I was thinking I could tune with the sensor on one bank, and then check by moving the sensor to the other bank.Escaped on a technicality.

Comment

-

Tank venting: I just drilled a couple of small holes in the bottom of my locking fuel tank cap. Problem solved.Life is short. Be a do'er and not a shoulda done'er.

1969 Galaxie 500 https://bangshift.com/forum/forum/ba...ild-it-s-alive

1998 Mustang GT https://bangshift.com/forum/forum/ba...60-and-a-turbo

1983 Mustang GT 545/552/302/Turbo302/552 http://www.bangshift.com/forum/forum...485-bbr-s-83gt

1973 F-250 BBF Turbo Truck http://www.bangshift.com/forum/forum...uck-conversion

1986 Ford Ranger EFI 545/C6 https://bangshift.com/forum/forum/ba...tooth-and-nail

Comment

-

I've been relying on the factory vent tube set up on the 71 Mustang since I've had the car. When I had the tank out to add a relocated return bung I looked more carefully at the set up. While the line that comes off the fitting to the front and then all the way round the tank to the back, thorugh the trunk floor around two full loop and out under bumper is steel 5/16's, the hole in the tank fitting itelf is maybe .025".

On the other hand, the vent tube on my 5 gal. race fuel tank is #8.

Im thinking the main tank setup is way too complicated, heavy, awkward and too small. Is there a standard for vent size? I have a non-vented factory style flip down filler cap.

Sorry for the hi-jack but the answer might be useful for all of us doing EFI retro fits.Last edited by CDMBill; March 26, 2012, 01:35 PM.Drag Week 2006 & 2012 - Winner Street Race Big Block Naturally Aspirated - R/U 2007 Broke DW '05 and Drag Weekend '15 Coincidence?

Comment

-

As to AFR, I liked the in car guages idea so I went with two of the LC1's. I don't necessarily wnat to drive the car with the laptop connected all the time so these have worked out well. I have one connected to the EMS-Pro (Megasquirt 2) and I can datalog that one. and just swap the 0-5v output wire to log the other guage and the other side of the motor. Every so often while driving i see some readings that usually are on the fat side which reminds to go back and do a bit more drive time tuning.

Location is temporary as I had the two guage little panel laying around.

When I upgrade to the MS3 I'll be able to log both guages.Drag Week 2006 & 2012 - Winner Street Race Big Block Naturally Aspirated - R/U 2007 Broke DW '05 and Drag Weekend '15 Coincidence?

Comment

-

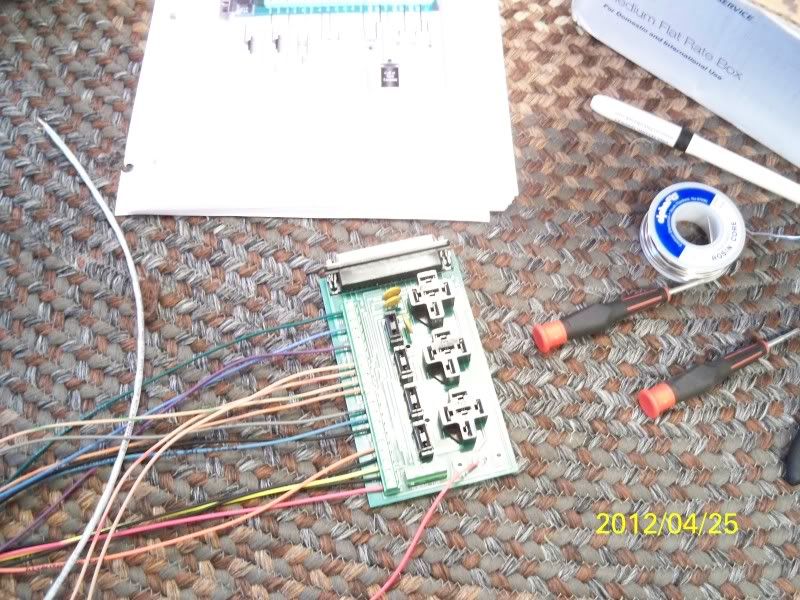

In between dealing with contractors and bankers and renters and elementary schools - I finally found a bit of time to assemble the relay board.

No wonder they don't really provide instructions. Its really THAT simple.

Started to sort thru and read the wires from the bundle. I used to work at a wire factory, and let me say, some of those stamped on labels are a little faint. Could have used a bit more time on the heat stamp.....

But it seems like they sent plenty of length, and at first glance there is a fair number of the wires I'll probably not need, at least at this stage.Of all the paths you take in life - make sure a few of them are dirt.

Comment

-

setting up the relay board in the living room, kind of a dry run to familiarize myself with it, and to make a chart for the wire colors and their intended location. Went well, and I tinned the wire ends that get screwed to the relay board.

Question 1 - - what size wire are you guys using for the power and ground feed to the relay board? I'm assuming something in the 14-12 guage range? Those do not seem to be included in the wire bundle.

Question 2 - - the shielded wire for the tach signal has 2 leads in it plus the shielding wire. Any special precaution to take with the second wire to prevent some weird signal loss? Or just trim it back and pretend it isn't there?

And where is the best place to ground it on the relay? Just jump into one of the other sensor grounds?

Of all the paths you take in life - make sure a few of them are dirt.

Of all the paths you take in life - make sure a few of them are dirt.

Comment

Comment