Well, I finally had a bit of spare time to spend with the MegaSquirt that Santa brought. Its a little intimidating when first opening the box and seeing the barage of teeny-tiny bits that go into these things, but a little reading in the MegaManual and a couple of "dry-runs" generate a lot of confidence. The DIY guys do a great job of making this process as simple as it can be.

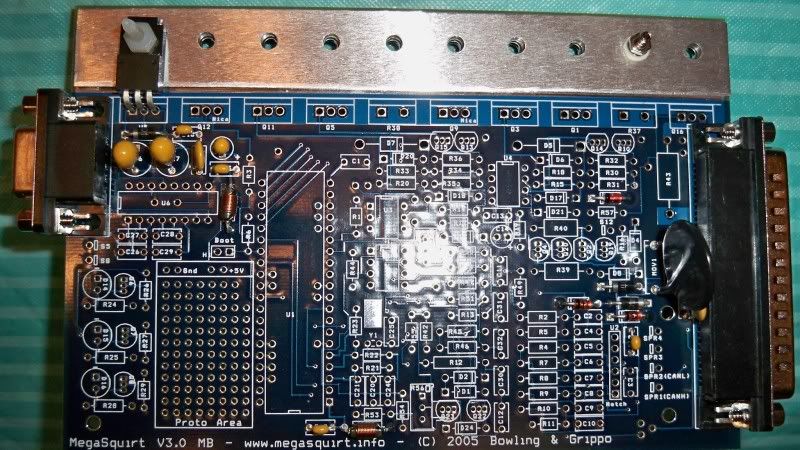

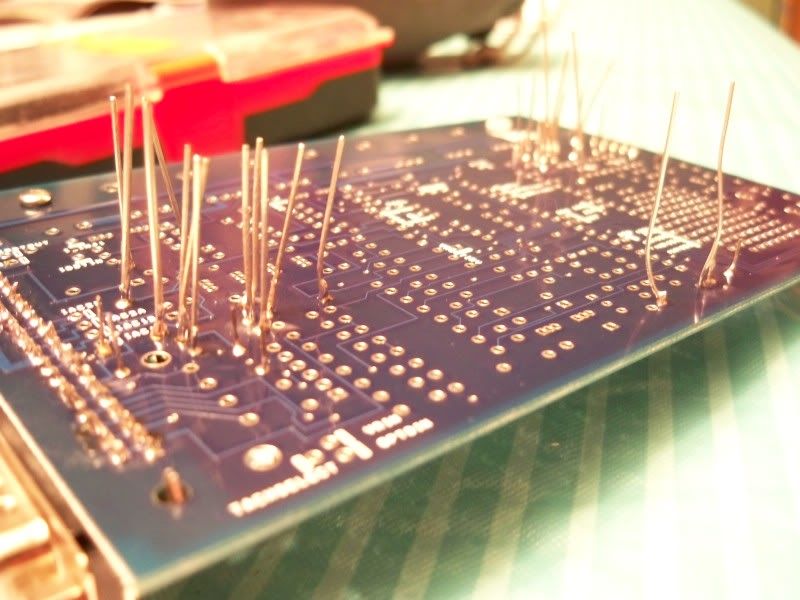

So here is what greets you upon first diving in.

I decided to splurge and treat myself to a new soldering iron, as my old Weller iron from 1982 has earned its retirement many times over. Has it really been 30 years since Grandpa gave me that Weller for Christmas? Yikes.....

Anyway, here is the replacement. Nice to have a stand and wipe pad, the temperature adjustablity is nice too. This bad boy set me back a whopping $16

I set up shop on the dining room table (wife was a little later than usual getting home last night, Suprise Honey!) Nothing fancy, just ran an extension cord and used the printed-off Megamanual for a work surface. Nothing but the best here at Club Med. Kids were intrigued too.

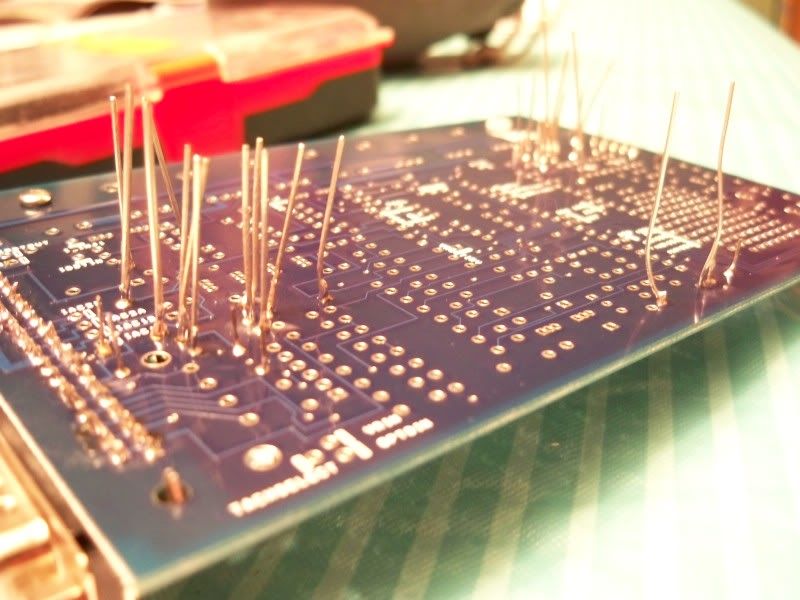

I got into the groove pretty quickly and in 1 1/2 hours I had this to show for my time. Found it nice and relaxing too, good change of pace from the normal havoc.

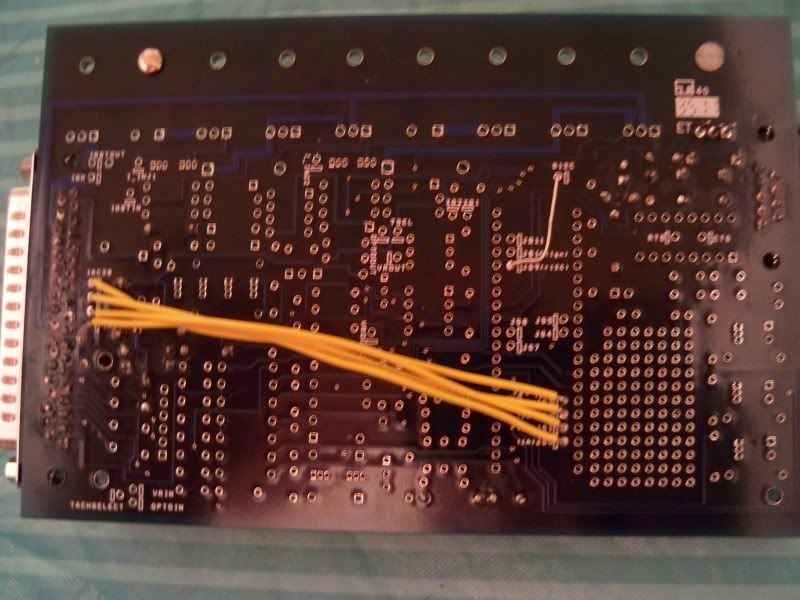

And the hairy side. I decided not to trim as I went, will just do that all at once as I clear a stage.

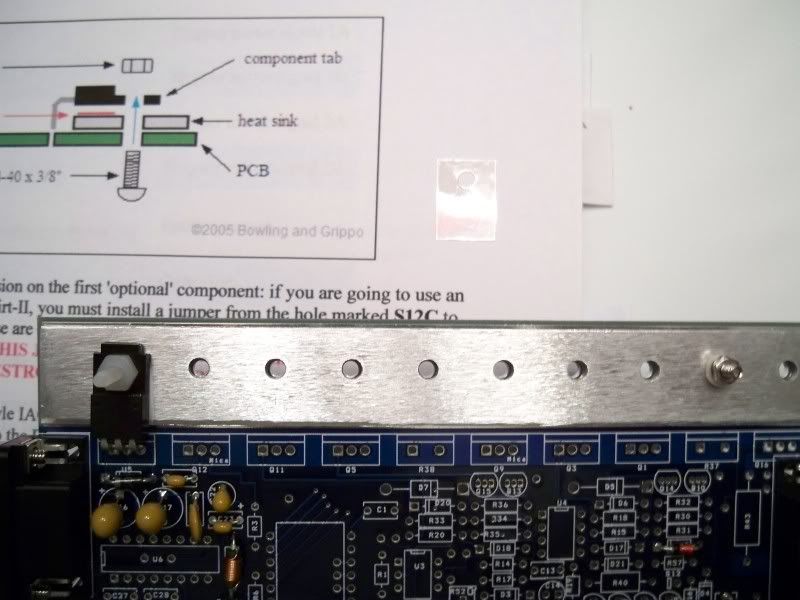

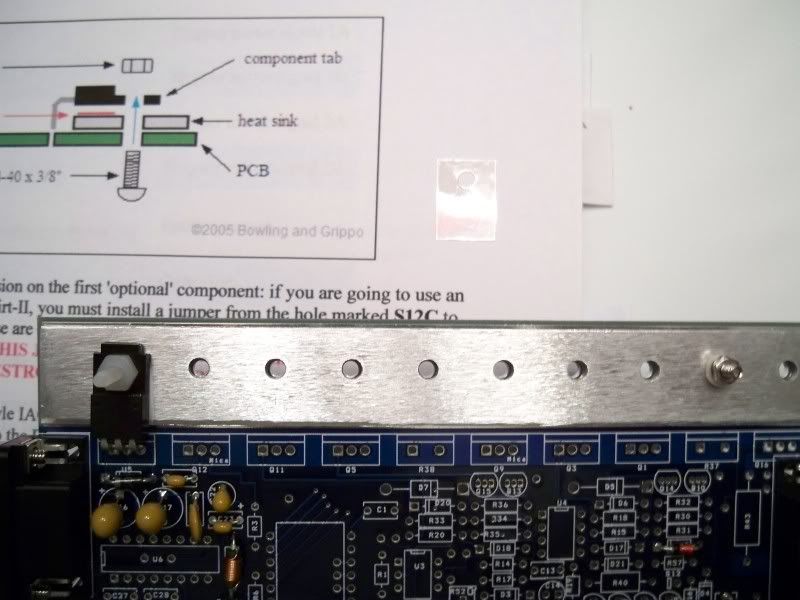

Found a good stopping point and a question. Each packet of fasteners for the heat sink has one of these little clear plastic shim pieces with a hole in it, but the manual doesn't address them. The picture in the manual doesn't show it either.

Should I just consider them "extra" parts or would it be a good idea to incorporate them? Shim piece is on paper just above PCB....what is this piece normally if I don't need it? Just curious, that's the whole point of this project for me anyways, learning new stuff.

And just to be sure - no heat sink grease between the PCB and aluminum heat sink itself? That's how I read the manual, though it didn't actually say.

So here is what greets you upon first diving in.

I decided to splurge and treat myself to a new soldering iron, as my old Weller iron from 1982 has earned its retirement many times over. Has it really been 30 years since Grandpa gave me that Weller for Christmas? Yikes.....

Anyway, here is the replacement. Nice to have a stand and wipe pad, the temperature adjustablity is nice too. This bad boy set me back a whopping $16

I set up shop on the dining room table (wife was a little later than usual getting home last night, Suprise Honey!) Nothing fancy, just ran an extension cord and used the printed-off Megamanual for a work surface. Nothing but the best here at Club Med. Kids were intrigued too.

I got into the groove pretty quickly and in 1 1/2 hours I had this to show for my time. Found it nice and relaxing too, good change of pace from the normal havoc.

And the hairy side. I decided not to trim as I went, will just do that all at once as I clear a stage.

Found a good stopping point and a question. Each packet of fasteners for the heat sink has one of these little clear plastic shim pieces with a hole in it, but the manual doesn't address them. The picture in the manual doesn't show it either.

Should I just consider them "extra" parts or would it be a good idea to incorporate them? Shim piece is on paper just above PCB....what is this piece normally if I don't need it? Just curious, that's the whole point of this project for me anyways, learning new stuff.

And just to be sure - no heat sink grease between the PCB and aluminum heat sink itself? That's how I read the manual, though it didn't actually say.

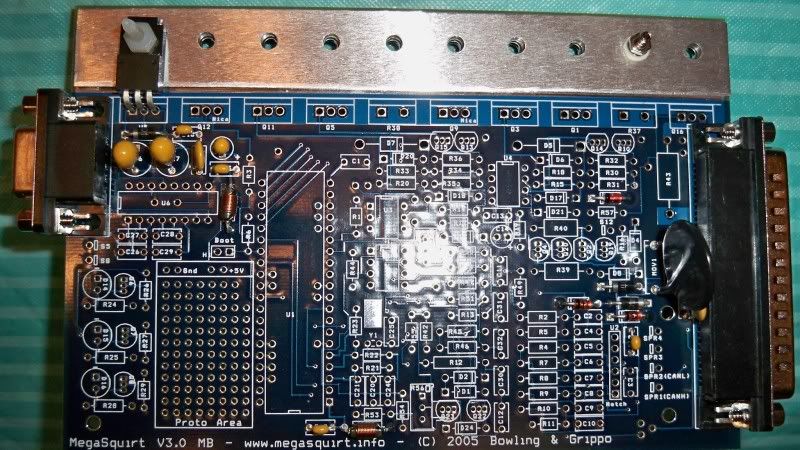

Dang this picture was taken in February 2008, almost 4 years ago. Didn't get it running on the MS until around October though.

Dang this picture was taken in February 2008, almost 4 years ago. Didn't get it running on the MS until around October though.

Comment