Hackery 101.

Some day I'll apply fuel to mine and see if they leak 35/64 bit, a small dremel to round the entrance for the o-ring insertion and NPT tapped ends

35/64 bit, a small dremel to round the entrance for the o-ring insertion and NPT tapped ends  Lets see how good O-rings are

Lets see how good O-rings are  It'll be bench tested/pressurized before being installed into the car.

It'll be bench tested/pressurized before being installed into the car.

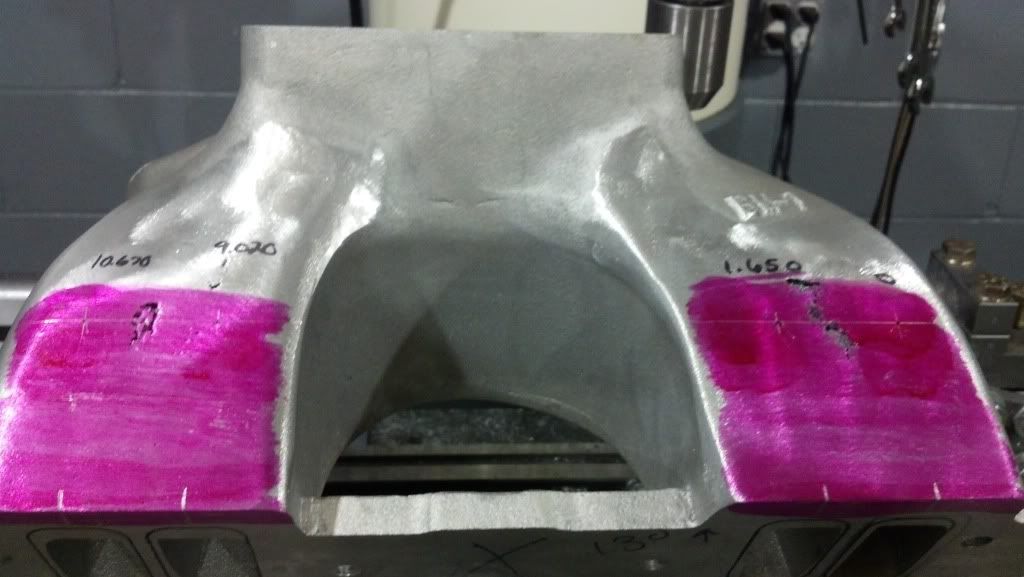

I just drilled them until the bit fully went into the fuel passage. This picture has the injectors pushed too far in, I had to pull them out a bit to install the electrical clip, so I'm guessing the top of the injectors are about flush with the fuel passage.

I still have to figure out how to retain the rails on the engine. I'm thinking a J-shaped plate from the cam housing bolts to the rails. I'll have to pull the rails off again to drill a bolt hole, but it'll probably be how I hold them in place.

Some day I'll apply fuel to mine and see if they leak

35/64 bit, a small dremel to round the entrance for the o-ring insertion and NPT tapped ends

35/64 bit, a small dremel to round the entrance for the o-ring insertion and NPT tapped ends  Lets see how good O-rings are

Lets see how good O-rings are  It'll be bench tested/pressurized before being installed into the car.

It'll be bench tested/pressurized before being installed into the car.

I just drilled them until the bit fully went into the fuel passage. This picture has the injectors pushed too far in, I had to pull them out a bit to install the electrical clip, so I'm guessing the top of the injectors are about flush with the fuel passage.

I still have to figure out how to retain the rails on the engine. I'm thinking a J-shaped plate from the cam housing bolts to the rails. I'll have to pull the rails off again to drill a bolt hole, but it'll probably be how I hold them in place.

Comment