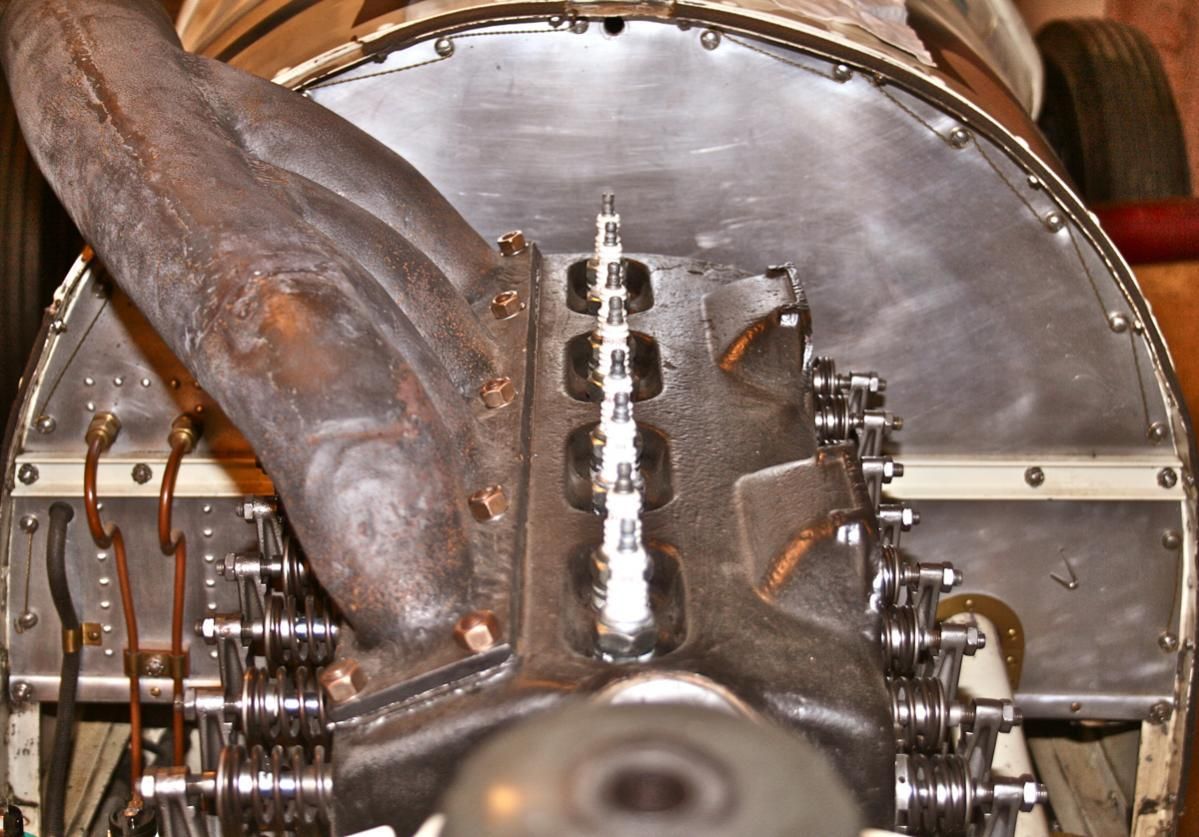

Tom, I have noted the seeming lack of attention to performance on the intake side as well. I have a theory, but obviously no way to verify it. The theory is that they wanted to lug the motor at extremely low rpm in high gear without bucking or stalling. You can't do that with multiple carbs, because the low air velocity in the carbs will not create enough pressure drop to pull fuel into the venturie.

I read in some old literature that people who bought Duesenbergs new often specified a deep rear end gear, especially if they lived in the city. Not so that they could peel out of the hole, but so they didn't have to downshift unless they stopped. So they'd get it in high gear, and lug it down to 5 mph if need be. Don't bother to double clutch, match the gear speeds and drop a gear. I think this was a big selling point of the car. You could go from 5 mph to 100+ in high gear. (I know that Cadillac used that in their sales pitch for their 452 cid V-16 that was introduced in 1930)

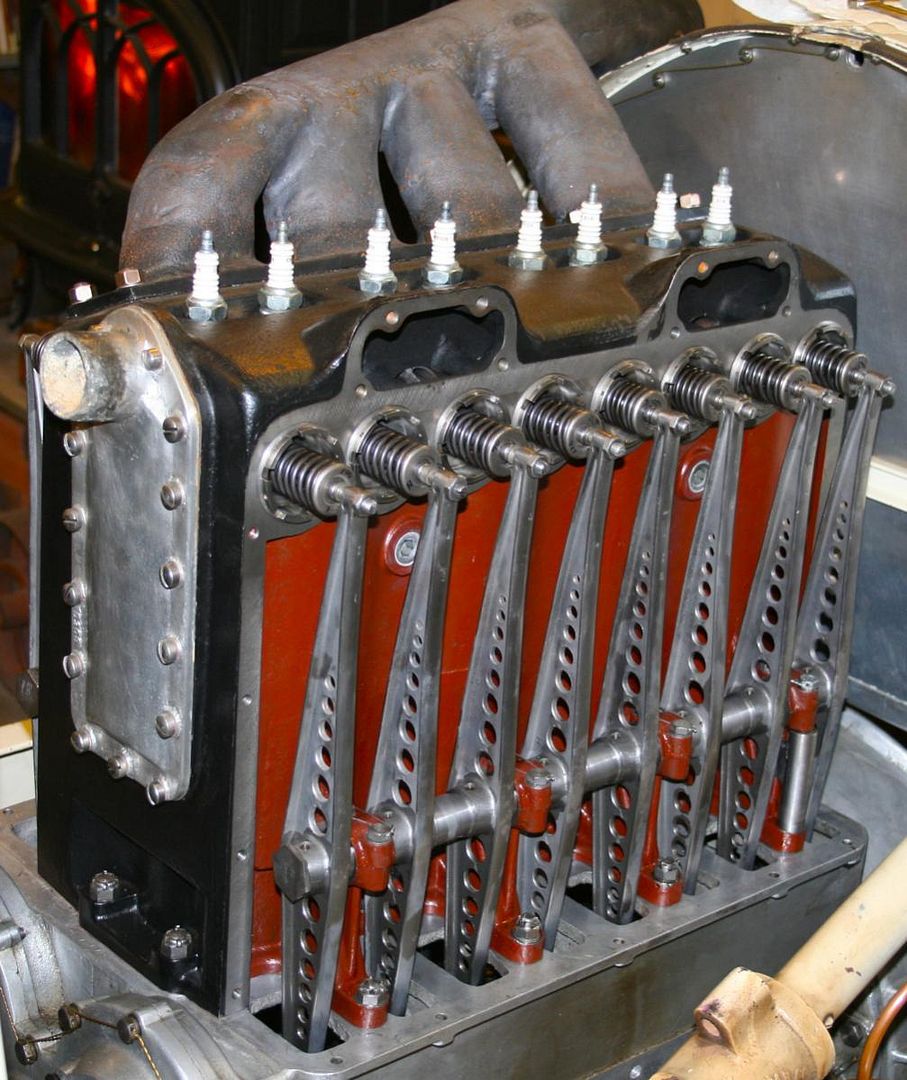

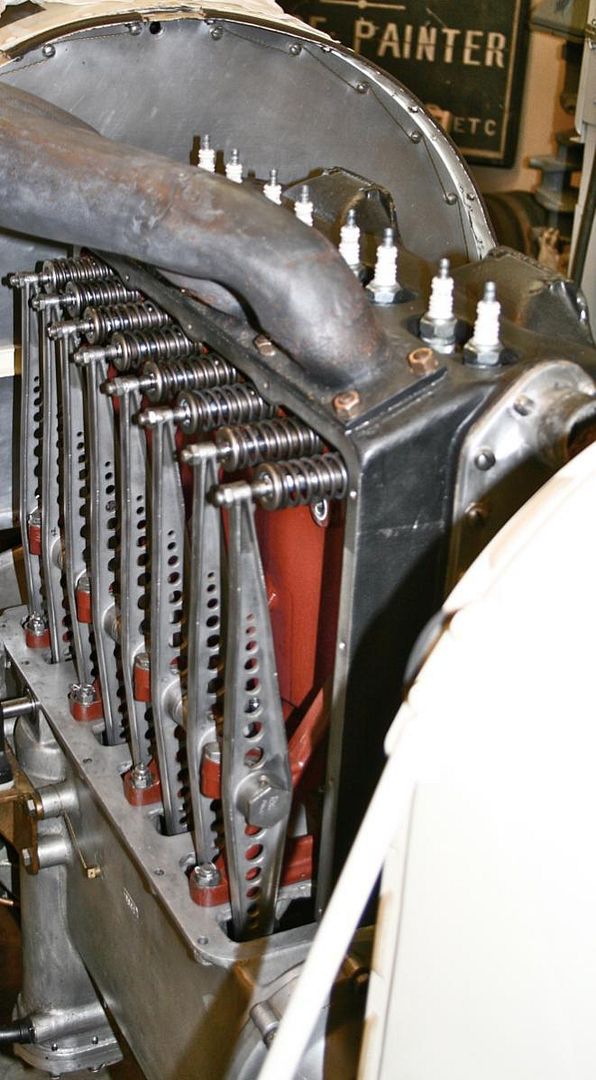

In 1932, they made a supercharger available with a single carb, rated at 320 BHP. Then a dual carb set up at 400 BHP.

5.5 to 1 compression was due the low octane gas at the time. Could they have gone higher? Probably. But I suppose there would be trade offs. Like maybe risk multiple occurrences of engine damage from crap gas in a higher compression engine ruining their reputation. And they already had the field more than covered in power, so why risk it? I'm just speculating here.

I read in some old literature that people who bought Duesenbergs new often specified a deep rear end gear, especially if they lived in the city. Not so that they could peel out of the hole, but so they didn't have to downshift unless they stopped. So they'd get it in high gear, and lug it down to 5 mph if need be. Don't bother to double clutch, match the gear speeds and drop a gear. I think this was a big selling point of the car. You could go from 5 mph to 100+ in high gear. (I know that Cadillac used that in their sales pitch for their 452 cid V-16 that was introduced in 1930)

In 1932, they made a supercharger available with a single carb, rated at 320 BHP. Then a dual carb set up at 400 BHP.

5.5 to 1 compression was due the low octane gas at the time. Could they have gone higher? Probably. But I suppose there would be trade offs. Like maybe risk multiple occurrences of engine damage from crap gas in a higher compression engine ruining their reputation. And they already had the field more than covered in power, so why risk it? I'm just speculating here.

Comment