Start with the ground since thats the easiest!

Go the Bruab route- Cherry bombs right of fhe headers.

Announcement

Collapse

No announcement yet.

The War Wagon... decaring wars on the grocery store since 1966

Collapse

X

Collapse

-

once again, if it wasnt for this website, I'd have been calling on a tow truck more than once.

Put a gallon of fluid into the trans, on top of what was already in there and that seemed to have fixed the issue of why it felt like the brakes were dragging, which they were not after all.

I need to call Bowtie OD and talk with them, Im trying to get the TV cable set, ive got it close I can tell. I drove it to the gas station and around the block, with moderate throttle it will go into what I think is 2nd and 3rd. It wont shift into 4th though, idk if its because I didnt go fast enough, the rear gearing is wrong for this trans or if I am really starting out in 2nd and its shifting into 4th gear. I need to bite the bullet and get a tachometer to see what the engine is doing. I need to do some more tweaking because it will rev pretty high before it will change into the next gear. but the shifts are firm and positive.

only other thing I can think of is that the vacuum switch for the OD lock-up isnt grounded enough so its not shifting into 4th gear for that reason.

any ideas? cuz Im stumped.

*probably wont drive it again till monday when I can call Bowtie. I dont want to break anything. plus with the center part of the H-pipe cut out, its extremely loud, the cabin fills with fumes quickly and I am suprised I have not had the cops called on me. well, sort of surprised, pretty much everyone at the office knows I own what is probably the only gold '60s GM full size wagon in the county. for now I may just go to the auto parts store, get some exhaust tubing and cut out the rest of my factory exhaust, which is rubbing the tires anyway and just make some home made dumps with some cheap mufflers for now. or see if I can salvage the stock ones, tho they are pretty much junk, one looks like its mostly Jb weld.

Leave a comment:

-

thanks, it didnt have a stud on it, the TV made ez from Bowtie ODs fit perfectly, followed their instructions to the letter. Leave it to GM tho to make something that is so simple yet so complex be the one thing that can grenade a transmission in no time at all lol

I hadnt planned on touching the Ebrake, but the cable system for it had a small bar that connected it to the trans cross memember. since I changed the crossmember, I couldnt get the OE bar that holds the cable to hook back on so right now the cables are kind of floating in the wind, there is a chance that it is still engaged. I was really tired yesterday so after I limped it down the street and pissed off my neighbors, I parked it and figured I'd mess with it today. I guess the info I read online was wrong, will have to go pick up another thing of trans fluid today. I dont have to work this weekend so I'll play with it some. I doubt I hurt anything cuz I hardly even moved the car. just hoping its something stupid simple.

Leave a comment:

-

IDK what type carb your Summit is...

Later model Q-Jets should have the tv stud in the correct location already, being factory parts and such.

Hope this helps.

If I think about it I can take pics of early & late Q-Jet throttle levers to show which style will already have the correct tv stud location.

Leave a comment:

-

Not trying to scare you but if the tv cable isn't real close you could kill a trans in a mile. And on that note my hi-perf 200-4r is going to meet its maker Monday...off topic.

Did you check the fluid level while the trans was hot? You should have. Anytime I've swapped a trans & converter they have taken close to 10 quarts of fluid to be full. An auxiliary cooler and deep tranny pan only add to the volume of fluid needed to fill the system, sans those two items the system could/should take 7 quarts.

To get real close on the tv cable setting:

1) install cable in throttle/tv cable bracket...mine are home-made to fit the applications because I haven't found an aftermarket version I like and they are EXPENSIVE to be trying one then another until some picky snit is happy.

2) install cable end on throttle arm of carb...late AFBs have a hole at the bottom of that arm that is CLOSE to the correct location to connect a tv cable but should have a geometry corrector installed. Everybody makes them (Jeg's, Summit, Edelbrock, etc, etc) for a variety of carbs but each brand/style of carb requires its own so shop with that in mind.

3) make sure the tv cable adjustment slider is all the way to the rear...there is a "button" to push to allow it to retract...may have to do each manually...push button with one hand, move slider with other

4) with the engine & key OFF, move the throttle lever to full throttle with your hand. The tv cable adjuster SHOULD pull out on its own, evidenced by audible clicking. The idea is to have full throttle & full tv pull at the same time.

I'm sure you did all this as it should be laid out in the instructions.

Even if the e-brake was dragging now, did you do anything to make it drag any worse than it was before the trans swap? You can check to make sure this isn't an issue but IMO if you didn't touch the e-brakes during the swap, nothing should have changed. I wouldn't worry about rear gears yet.

And finally, the difference between a th350's first gear (2.52) and a 700r4's first gear (3.06), ANYTHING should act as if it instantly had 18% more balls than it did before the swap.

JM or quarters worth

or quarters worth

Leave a comment:

-

well I didn't do the drain plug, probably going to regret that and cost me a few Tshirts. I was just tired of seeing it on blocks.

got it all buttoned up. got the TV cable hooked up as per Bowtie OD's instructions, with the base setting they described.

car fired up with minimal effort, got the issue with the throttle linkage worked out, it just needed to be coerced. its not leaking any fluids, which is amazing.

car is rather loud since I cut the exhaust. I may just cut the rest out cuz the one side is rubbing the tire.

now the bad news, it runs, and "drives" but it has absolutely 0 none, nada, no balls. at first I thought the throttle was jamming up, which is why I coerced it to fit the right way. the pedal isnt overly stiff, but you put the pedal 1/4 way down and it just wont go. its driving like its only half in gear. it will drive, it just feels like it is dragging 2 sleeping elephants behind it I felt it shift, I didnt mash the pedal, because 1, the TV cable isnt 100% set yet, and 2, its LOUD and I dont want my neighbors to call the cops/get pulled over. I felt it shift into 3rd, and it felt like it was flip flopping in gear, not quite like it was slipping though. It has a 5 quart jug of trans fluid in it, plus 1 quart in the converter when I installed it.

only other thing it could be is the Ebrake, which currently due to the new crossmemeber, the cables are basically just there, not taut or anything, possibly the rear brakes could be stuck as a result?

Ive not hooked up a tach yet, plus the noise it makes is a bit misleading.

anyone have any tips/ideas?

TV cable not adjusted right?

not enough fluid?

rear gears being wrong? I have no idea what they are, but I imagine that they are a 2:something.

ebrake?

I only drove it maybe a mile. just to burn all the dust and spilled fluids off the exhaust.

id go fiddle with it more, but honestly, I am exhausted from work, right now im just happy it crawls under its own power for now.

any ideas will be most appreciated. i dont want to drive it cuz im afraid to break something expensive.

thanks

Leave a comment:

-

I too find a trans drain plug a convenient item to have and it sure makes maintenance & removal a LOT cleaner. I also understand decreasing patience as the end of a project nears. Main thing is that you are happy with the path you take. ENJOY

ENJOY

Leave a comment:

-

I'd rethink that drain plug thing. I just grab a 1/4" pipe coupling and cut it at an angle then weld it in sideways in the pan. Screw in a short length of 1/4" pipe as a drill guide and pierce the pan. Clean out all the metal bits and plug the hole with a brass pipe plug and you're done. By putting it sideways it doesn't hang down so it can catch on something. This method costs almost nothing. Every time I haven't added a plug I've kicked myself soundly at a later date when I need to drain the pan.

Dan

Leave a comment:

-

thanks! I got the kit from them, Ive read this before, plus they included extremely detailed instructions.Originally posted by 68scott385 View Posthttp://www.tvmadeez.com/article/index.php

Important information regarding tv cable adjustment & function. Three part article, something to keep handy for reference.

ran out and bought trans fluid and 3 pan bolts I was missing somehow. so so so so so so so tired of buying stuff. so I am cutting a couple corners. not buying a drain plug for the pan, cuz I forgot to and now I dont give a damn anymore. and ive not bought the tach... I'll get to it.

tomorrow I will attempt to light it off, will need to pour a little gas down the carb, it is bone dry from sitting for over a month.

Leave a comment:

-

Important information regarding tv cable adjustment & function. Three part article, something to keep handy for reference.

Leave a comment:

-

getting close finally, got the trans wired up, vacc line for switch run, new TV cable kit installed, just need to adjust it. I need to modify or make a new throttle rod/ convert it to a cable. the way it is, it hits the bracket for the TV cable. if I flip it upside down it clears. but then the air cleaner doesnt fit. for now, I dont care, I'll fix it after I get everything all set up and its running and shifting right. should have mostly done tomorrow, gotta read how to set the cable as per the instructions.

hopefully the battery has enough juice to crank it over.

Leave a comment:

-

nice! thanks man, I'll have to check tomorrow.Originally posted by Scott Liggett View PostYour fuse box should have three spades left of the fuses. Top one is fused ign hot, next one is battery hot, third is ign hot.

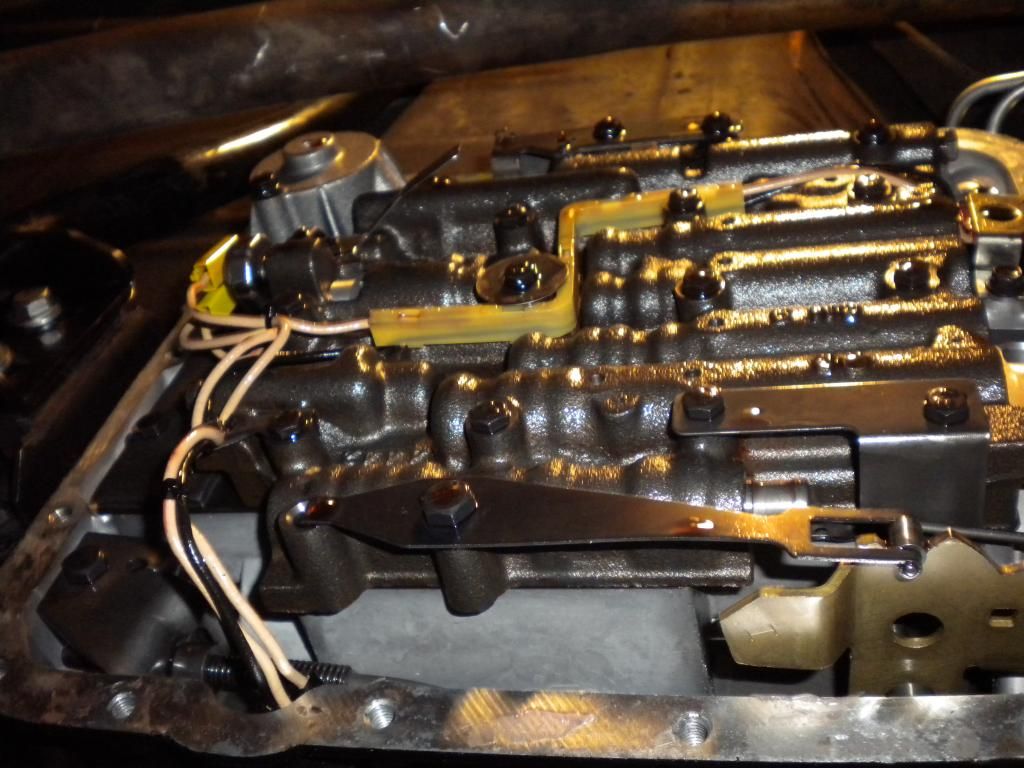

here are some pictures of the inside of the trans.

these are the two solenoid switches located at the back of the trans, not the front like I thought before. the green plug is the one with the single terminal. the one i am pointing at has 2 terminals.

route of the wires

I will leave all this alone for now and see how the transmission reacts for now.

from what I have read the TCI kit is Vacuum operated vs the B&M one which is speed operated. which is also two times as espensive

Leave a comment:

-

Your fuse box should have three spades left of the fuses. Top one is fused ign hot, next one is battery hot, third is ign hot.

Leave a comment:

-

no man, you are helpful.

I dont know if I have an extra slot in my fusebox, I have to look, cuz Its the old school glass fuses. unless I can run an auxillary fusebox for just the transmission and leave some spots open for future additions. unless that is getting too complicated and I am better off just running an inline fuse to a keyed source or maybe run it off the cigarette lighter, unless that would put a draw on the batter when the car is off.

electrics are my weak point.

and I do have a loose ground strap I ground on the caseLast edited by Shelty; June 22, 2014, 07:30 PM.

Leave a comment:

-

I ALWAYS source power for new circuits from the fuse box. Usually there is at least one unused keyed hot terminal, plug in one end of an in-line fuse there. I've even used a two-from-one adapter to feed more than one low-draw circuit, just make sure both circuits use fuses.

From what I envision from your explanation, you just need to supply 12v to the appropriate wire(s). I don't have any pictures of the valve body in my 700r4 but I was just in my built 200-4r, the switches in the valve body get their ground from the valve body/transmission. This is a good reason to add a ground strap from a bell-housing bolt or tail-shaft housing bolt to the frame or crossmember, or both in my case. I like to remain fully grounded.

I wound up with one of each after doing separate modifications...redundancy at its best. Anyway, by supplying the valve body switches with 12v they will close at their predetermined time/pressure to make the hydraulic valves do their thing. I understand what they do & how they do it, just not good at explaining it. I know I'm marginally useful.

I wound up with one of each after doing separate modifications...redundancy at its best. Anyway, by supplying the valve body switches with 12v they will close at their predetermined time/pressure to make the hydraulic valves do their thing. I understand what they do & how they do it, just not good at explaining it. I know I'm marginally useful.

Leave a comment:

Leave a comment: