Damn another month got by me, but I made a nice trip back home to hang with the kids. Also waited on engine parts, but now all that is done and waiting to go in vehicles.

And we are back to working on the 65! Today I cleaned up the inner wheel wells, hit them and the grille surround with POR15. Should be ready for a bit of metal work tomorrow, and then I will do the front fender patches. The engines I have been working on are almost done, so its time to get back into the body work.

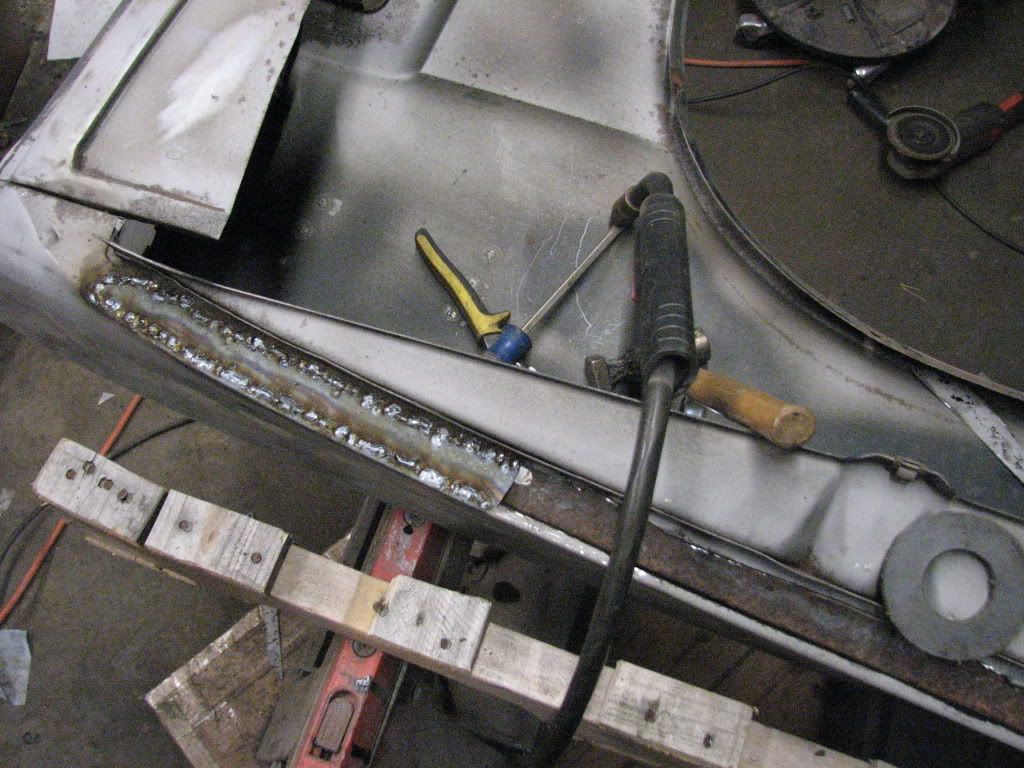

I am only waiting on one part that was back ordered, the headlight harness. I have the rest of the electrical system, so this thing should not have any wiring issues when its done. It wont be long and I will be shooting primer on this beast. Tomorrow, lots of welding.

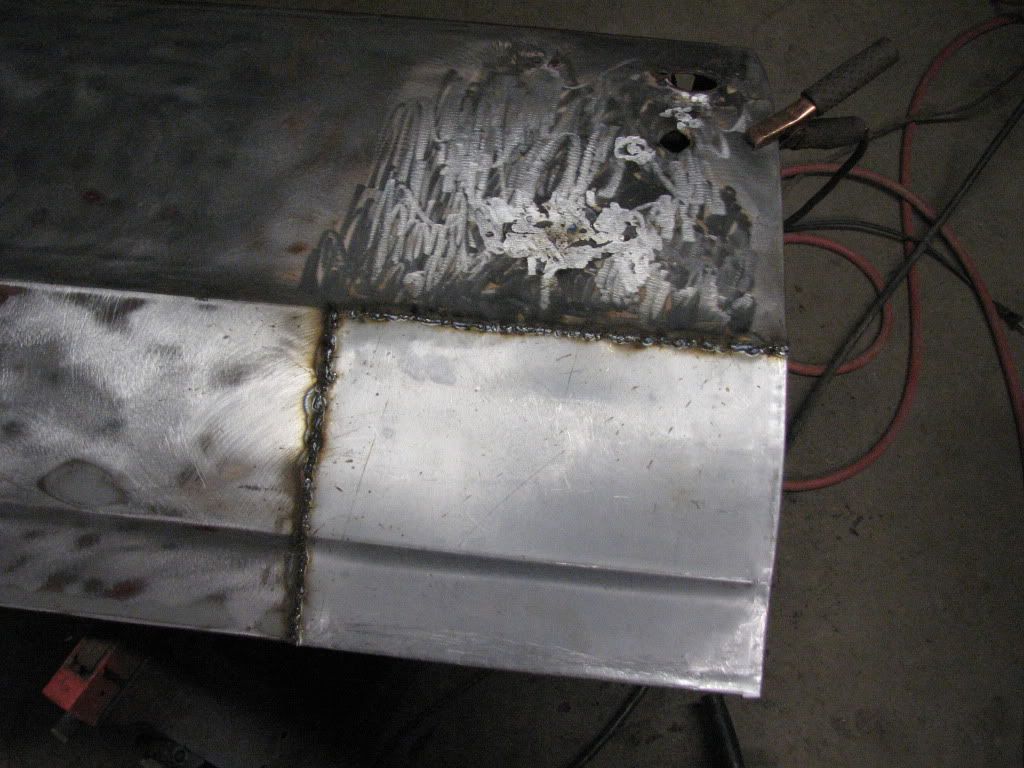

Here are the parts I painted today.

And we are back to working on the 65! Today I cleaned up the inner wheel wells, hit them and the grille surround with POR15. Should be ready for a bit of metal work tomorrow, and then I will do the front fender patches. The engines I have been working on are almost done, so its time to get back into the body work.

I am only waiting on one part that was back ordered, the headlight harness. I have the rest of the electrical system, so this thing should not have any wiring issues when its done. It wont be long and I will be shooting primer on this beast. Tomorrow, lots of welding.

Here are the parts I painted today.

Comment